Energy-saving casing of induction heating device universally used in iron section cladding sand cast production line

An induction heating device, iron mold sand-covered casting technology, applied in induction heating, casting molding equipment, casting molds, etc., can solve problems such as uncontrolled heating, parts failure energy consumption, etc., to achieve strong versatility and reduce energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

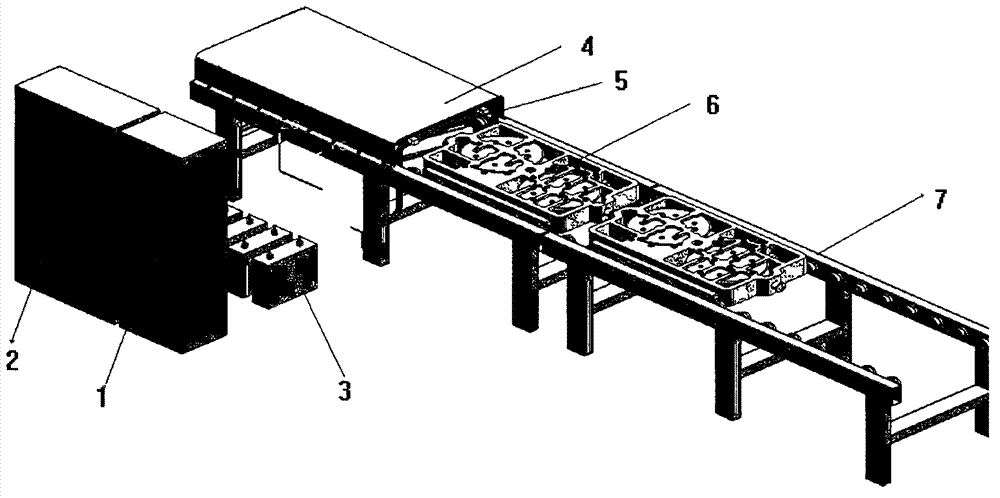

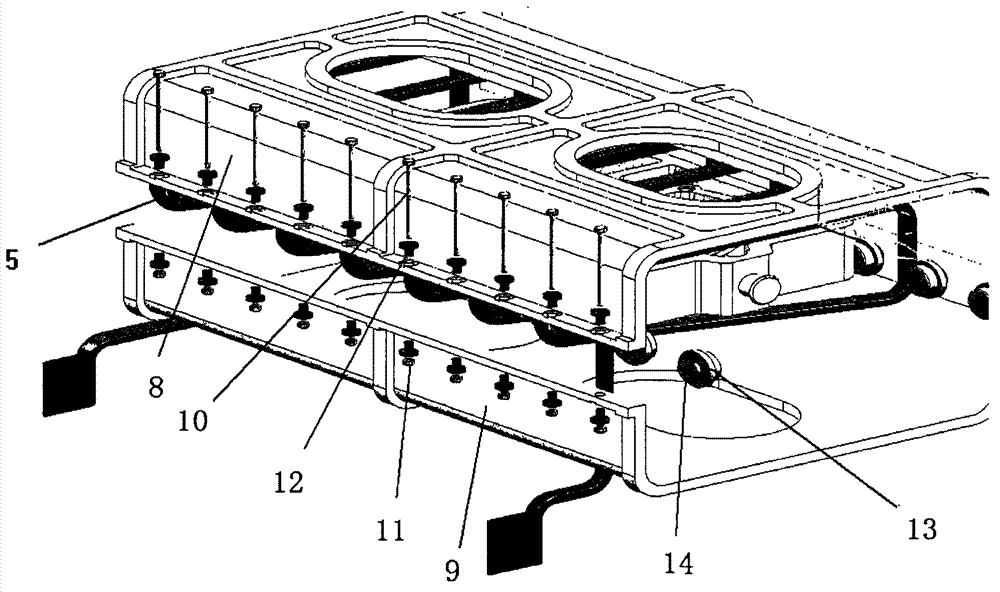

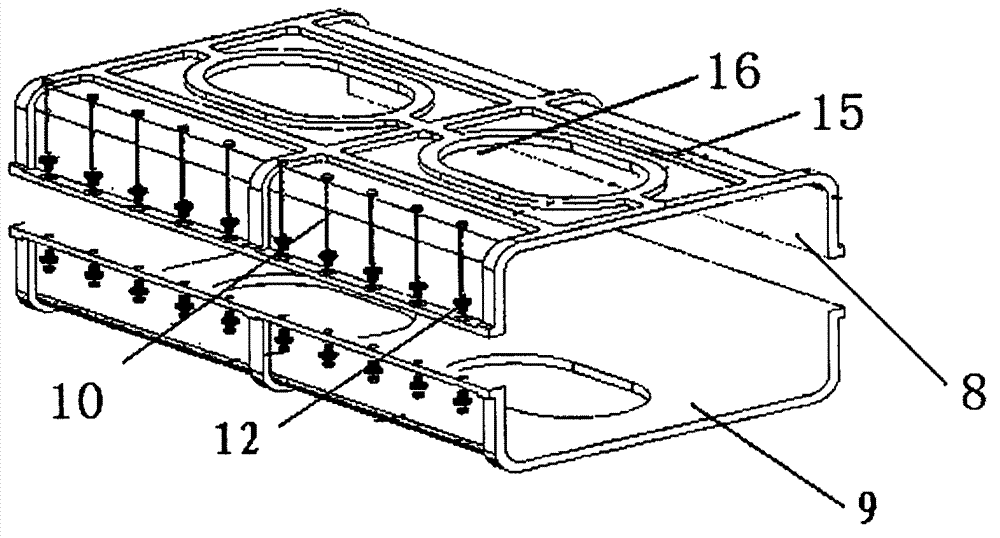

[0019] Such as figure 1 , 2 As shown, the iron-form intermediate frequency induction heating process components include a power switch cabinet 1 that provides control power, a power frequency conversion and rectifier cabinet 2, and a capacitor bank 3. The iron-form 6 is placed on the iron-form conveying section 7, and the iron-form passes through the outer wheel 13 of the idler roller. And heat-resistant bearings 14 are transported along the conveyor belt. The casing 4 is made of metal and installed on the iron-shaped conveying section 7. The surrounding of the casing 4 covers the induction heating device 5 and the iron-shaped conveying section where it is located. There are iron-shaped conveying inlets and outlets at both ends of the casing. The casing 8 and the lower casing 9, the upper casing and the lower casing are connected by fixing parts, and the upper casing and the lower casing are provided with ribs 15 and openings 16, and the openings are opened on the top of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com