Quick gear grinding device for disc gears

A gear and disc-shaped technology, applied in the field of fixture devices, can solve the problems that the installation accuracy affects the precision of gear processing, increase the labor intensity of workers, reduce production efficiency, etc., to improve product quality, reduce final time, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

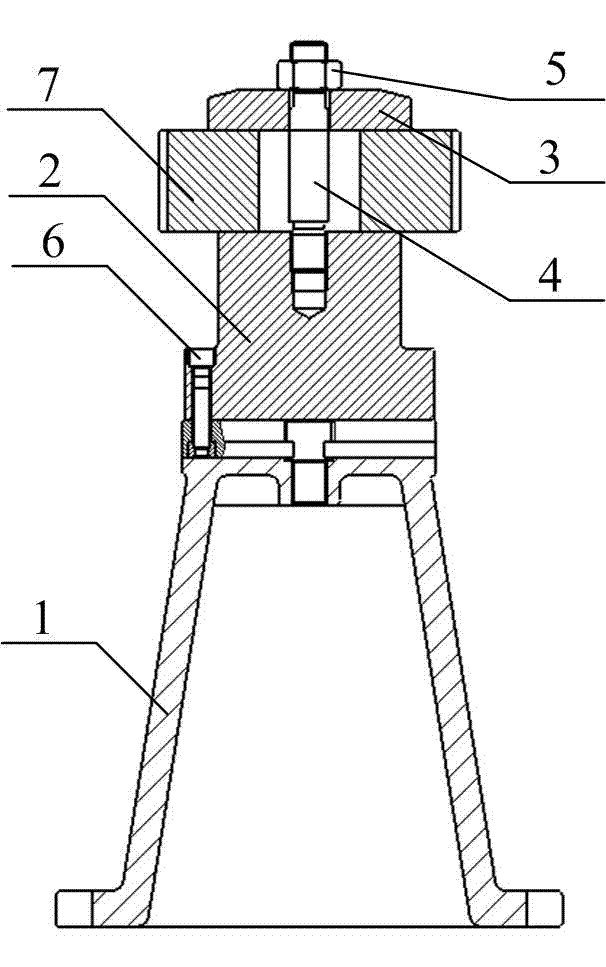

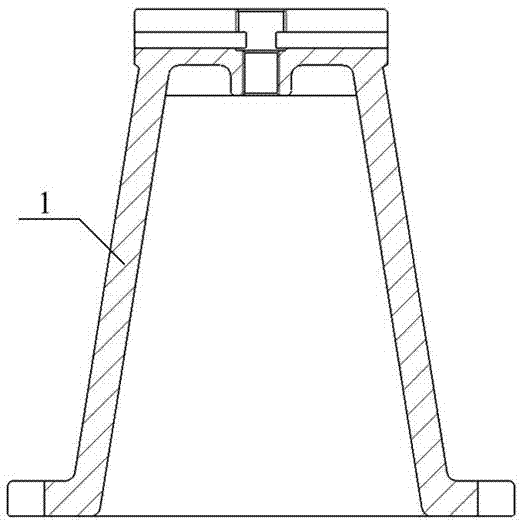

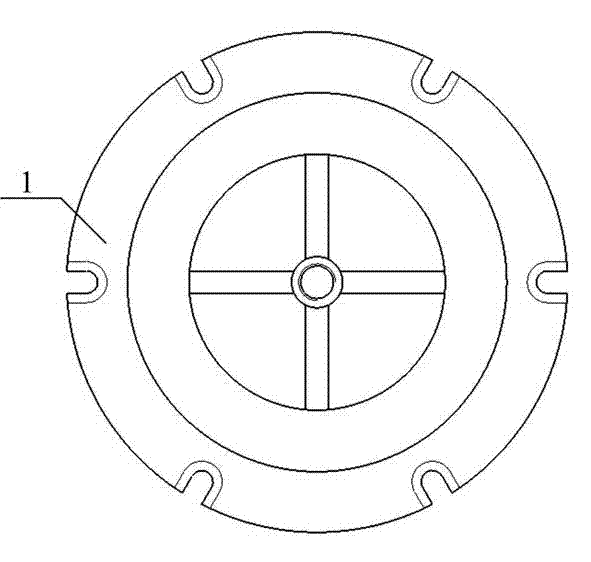

[0013] like image 3 As shown, the disc-shaped gear quick-change gear grinding device of the present invention includes a tooling table 1, a platform accessory 2 and a pressure plate 3, and also includes a screw 4 and a nut 5. The platform accessory 2 is installed on the tooling platform 1 through screws 6, The disc gear 7 to be processed is clamped between the platform attachment 2 and the pressing plate 3 through the screw rod 4 and the nut 5 .

[0014] The platform attachment 2 can be made into various specifications according to the external dimensions of the disc gear to be processed. When working, the tooling table 1 is installed on the surface of the workbench. After it is relatively flat, the matching platform accessory 2 is selected according to the outer dimension of the disc gear 7 to be processed and placed on the tooling table 1. It is fixed by the screw 6 and the screw rod 4 is installed. On the platform attachment 2, the disk gear 7 to be processed is placed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com