Welding method of orthotropic plate U-shaped rib fillet welding robot and special equipment thereof

A technology for robotic welding and orthotropic plates, which is applied in welding equipment, arc welding equipment, welding accessories, etc., can solve the problem of difficulty in ensuring consistency in the appearance of fillet welds, fluctuations in welding quality of U-shaped rib fillet welds, manual Operational low efficiency and other issues, to achieve the effect of complementary welding operations, high economic and social benefits, huge application value and market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The robot welding method of U-shaped rib fillet weld of orthotropic plate of the present invention, its steps comprise:

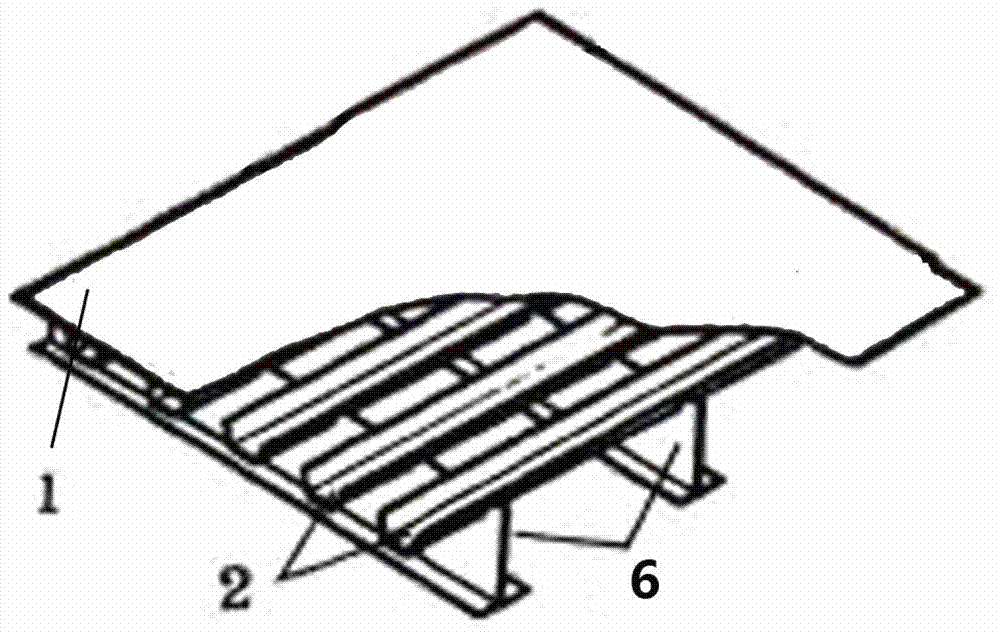

[0043] Preparation of U-shaped rib unit: U-shaped rib 2 is fixed on the bridge deck 1 by tack welding to prepare U-shaped rib unit 3; the specific operation process is as follows:

[0044]A-1. U-shaped rib groove processing and pressing: First, flatten the U-shaped rib 2 with a steel plate, then expand the width and length of the U-shaped rib 2 and reserve a certain amount of processing for blanking, milling on both sides of the steel plate and Process the fillet weld bevel, and then press it into a U shape on the molding machine;

[0045] A-2, bridge deck blanking: after the bridge deck 1 is flattened, it is unloaded;

[0046] A-3. Cleaning of the area to be welded: clean the rust, oil, moisture and other welding harmful substances in the area to be welded on the U-shaped rib 2, the bridge deck 1, and the range to be welded on both sides;

[0047]...

Embodiment 2

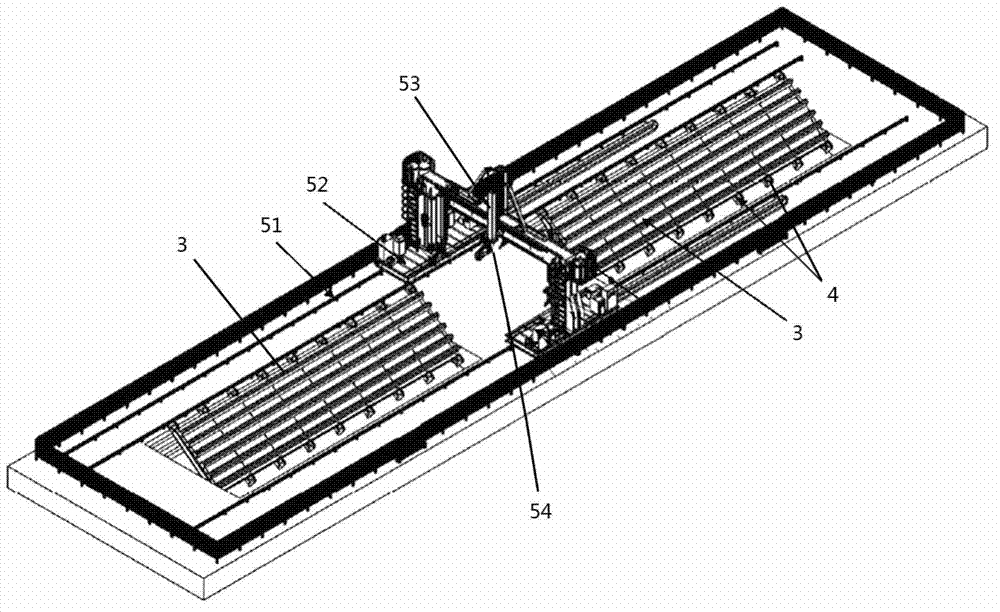

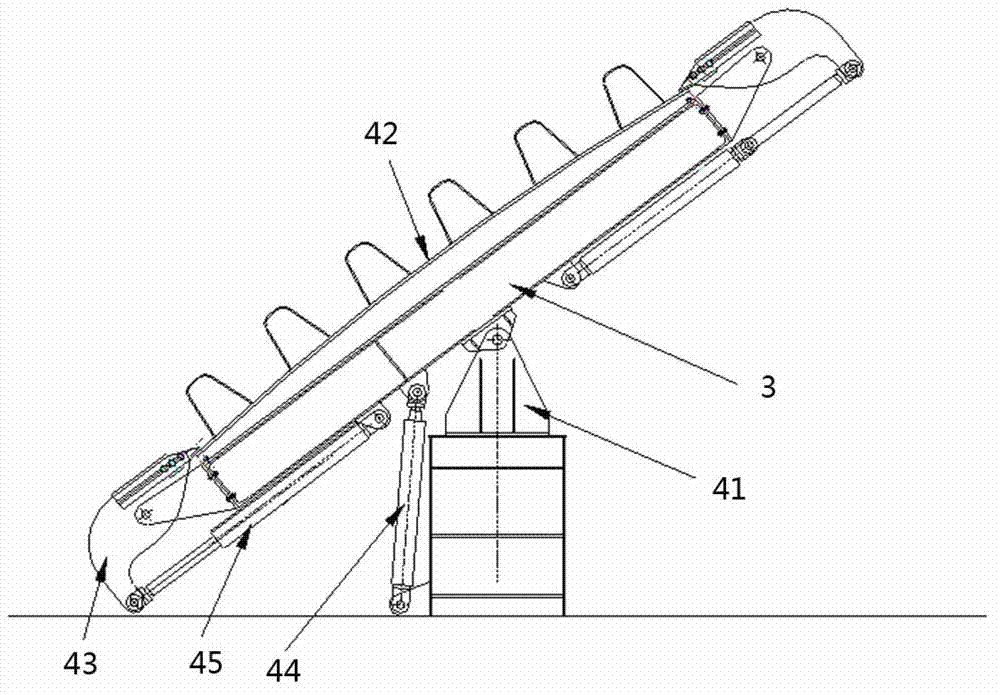

[0054] Special equipment for the robot welding method of U-shaped rib fillet welds on orthotropic plates, which includes a robot automatic welding system and an anti-deformation flip tire frame 4, both of which realize automatic interactive operations through the controller;

[0055] Among them, the robot automatic welding system includes a work platform 51, a mobile device 52 arranged on the work platform 51, and two sets of independent cantilever traveling mechanisms 53 arranged on the mobile device 52, and two sets of robot welding robots are arranged on each cantilever traveling mechanism 53. hand 54; the robot welding hands 54 communicate in real time through wired or wireless means, and correct the other welding hand in real time according to the welding conditions of one of the welding hands, so as to realize complementary welding operations; the robot automatic welding system also includes the overall control of the robot Cabinet, welding power supply, welding wire buck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com