Modular above-water platform

A water platform and modular technology, applied in ship propulsion, ship parts, ships, etc., can solve the problems of difficult pairing and assembly of modules, low cost performance, complex structure, etc., and achieve high flexibility, low cost, and fast assembly and replacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

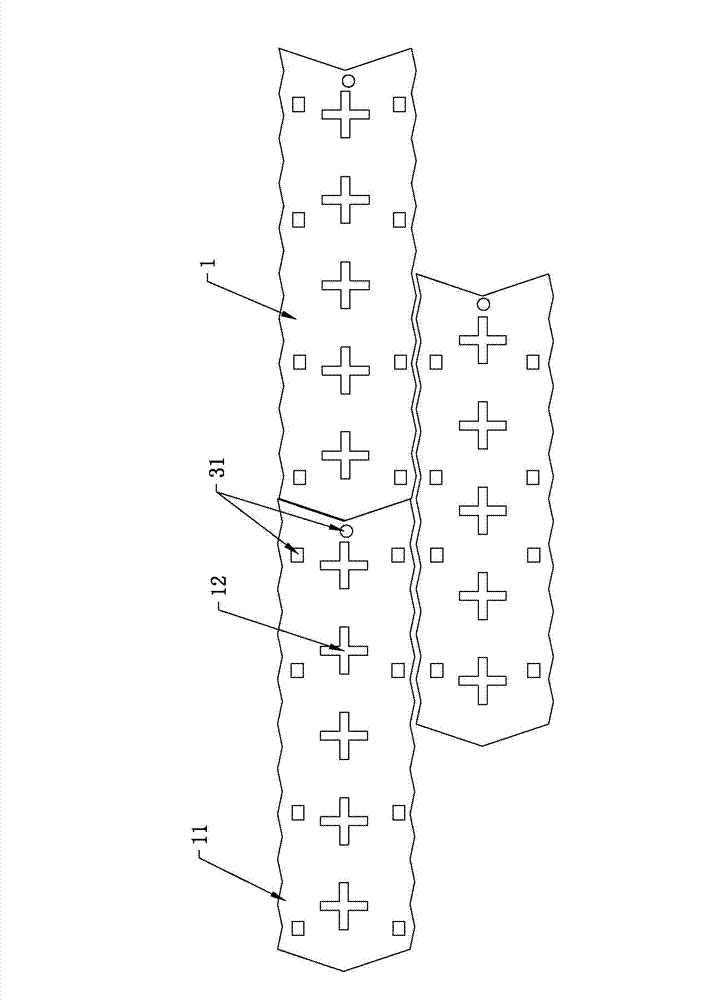

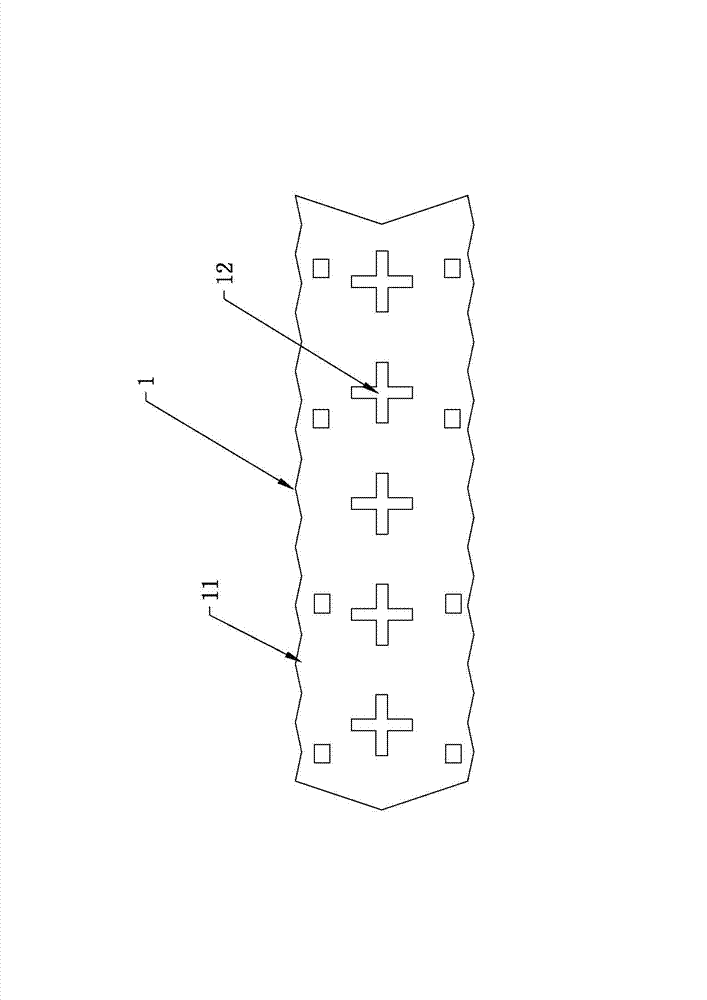

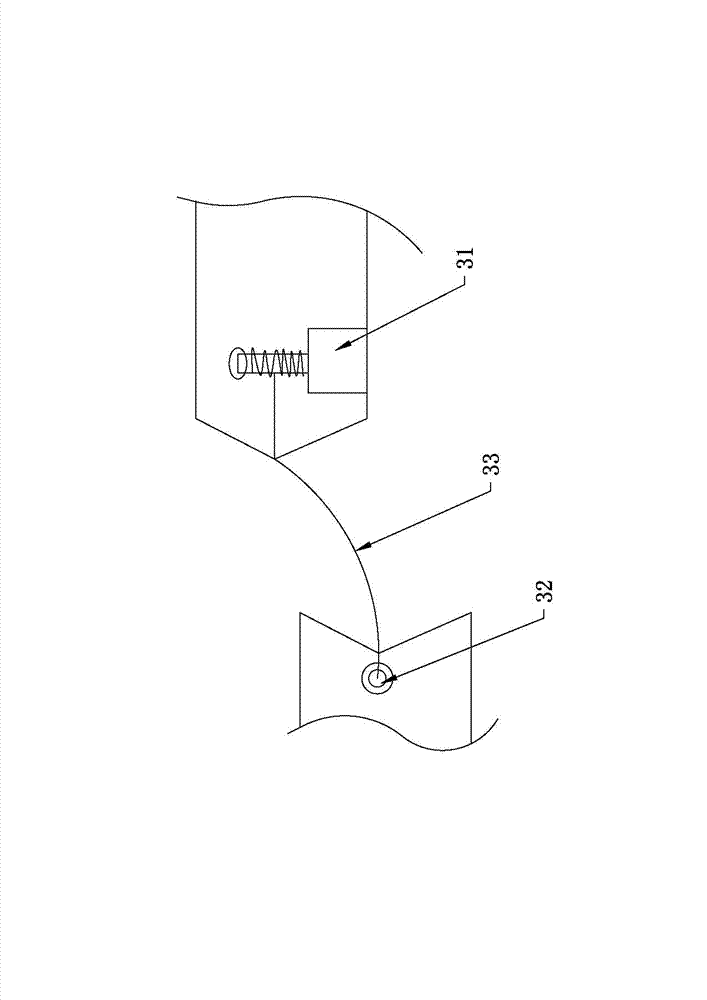

Embodiment 1

[0029] A modular water platform such as figure 1 As shown, multiple platform modules 1 are included. like figure 2 As shown, each platform module 1 includes a windlass, a platform layer, a plurality of connecting devices and a ship power device for driving the platform module 1, and the inside of the platform module 1 of this embodiment is also provided with a control cabin for the staff to operate , the controller is installed inside the control cabin. In this embodiment, both sides of each platform module 1 are equipped with a ship power plant, which effectively improves the stability of the platform module 1 on the water surface. The ship power plant in this embodiment includes a main engine, transmission equipment, shafting and propulsion etc., and the propeller is used as the propeller of the ship power plant of the present invention, when the main engine is started, the transmission equipment and shafting can be driven to make the propeller work, and the platform modu...

Embodiment 2

[0035] A modular water platform of this embodiment is different from Embodiment 1 in that the platform module 1 of the modular water platform of this embodiment is not equipped with a control cabin for personnel to operate, but is provided with a control server on the shore , each platform module 1 is wirelessly connected to the control server, and the operator controls the operation of each platform module 1 wirelessly through the control server on the shore. Other structures and principles of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

Embodiment 3

[0037] The difference between the modular water platform of this embodiment and Embodiment 1 is that the docking area 11 of this embodiment is a splicing protrusion provided on the four sides of the platform module. Other structures and principles of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com