Bearing head of underwater sonar electronic system for connecting trailing cable

An underwater sonar and electronic system technology, applied in the field of load-bearing heads, can solve difficult problems and achieve the effect of ensuring low-loss transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

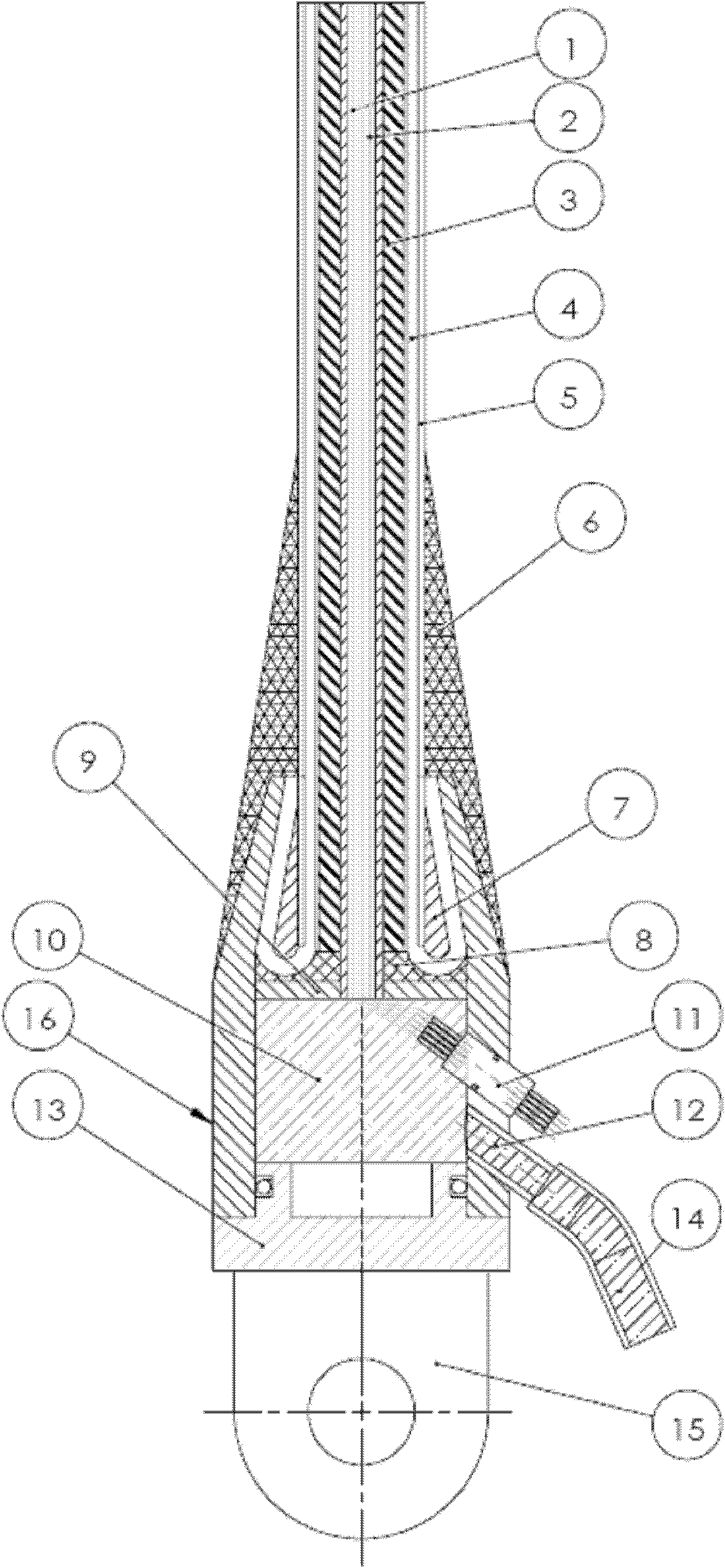

[0032] In order to better understand the technical solution of the present invention, the implementation steps of the present invention will be further described below in conjunction with the accompanying drawings.

[0033] Such as figure 1 As shown, the specific implementation method is to gently peel off the Kevlar layer 4 to a certain length, wrap the Kevlar layer 4 on the tapered cylinder 7 that locks the Kevlar, and tighten it so that it is embedded in the load-bearing head Inside the shell 16. Fix the oil-filled towline pressure-resistant sheath 3 on the upper sealing cover 9 of the sealed oil tank 10, fix and lock it with a locking screw filled with solid superglue 8, and secure the towline oil-filled pressure-resistant sheath 3 It is fixed on the upper sealing cover 9 of the oil-filled cabin 10. The optical fiber and the power line of the trailing cable are welded on the photoelectric hybrid watertight connector 11 to complete the switching of the photoelectric signa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com