Network electronic weighing system for forklift

A weighing system and weighing technology, applied in the direction of weighing, special scales, lifting devices, etc., can solve the problems such as the inability of the weighing system to realize the communication function of external equipment, the technical difficulties of enterprise network management, and the inability to meet the weighing results. , to achieve the effect of simple installation, low power consumption and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing.

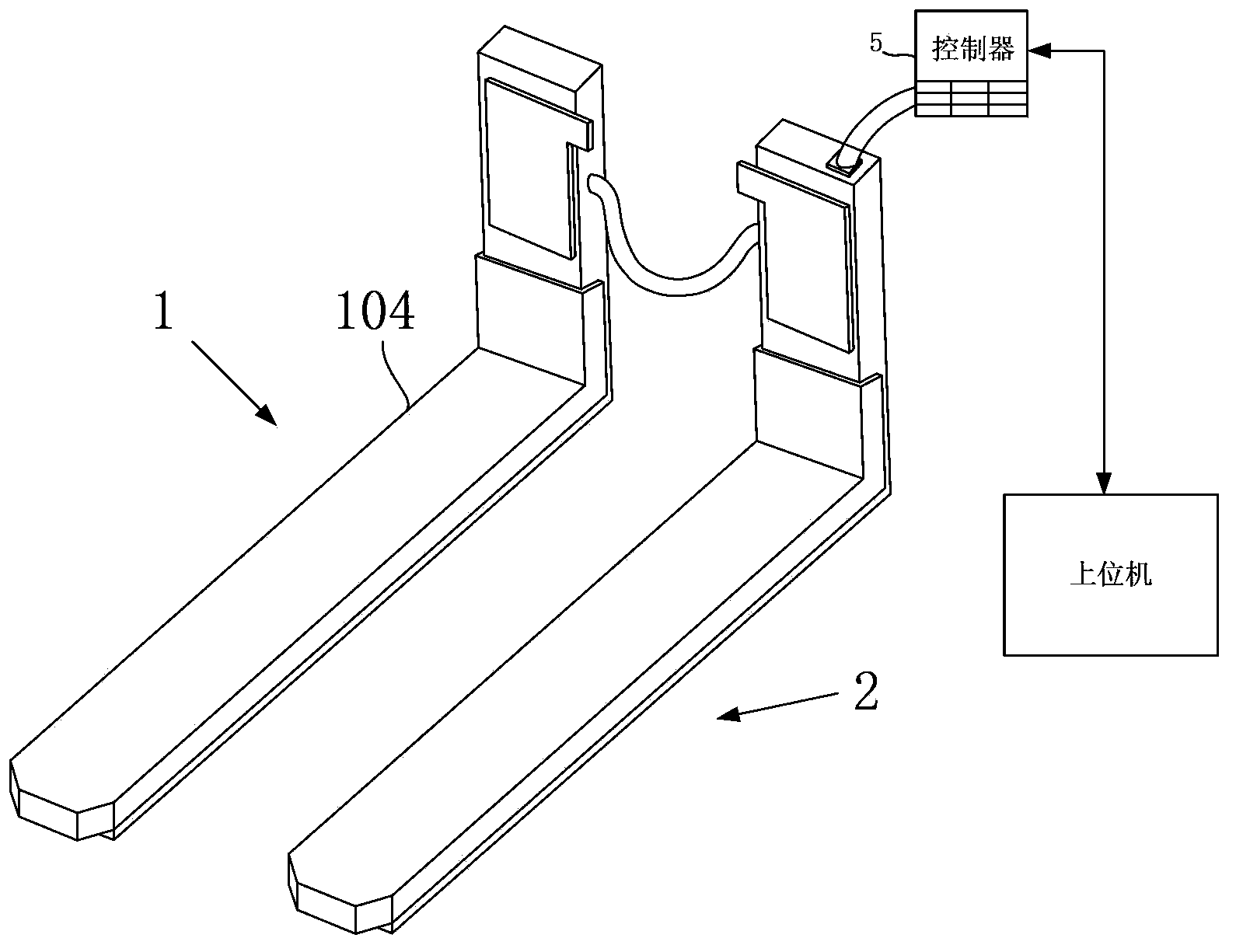

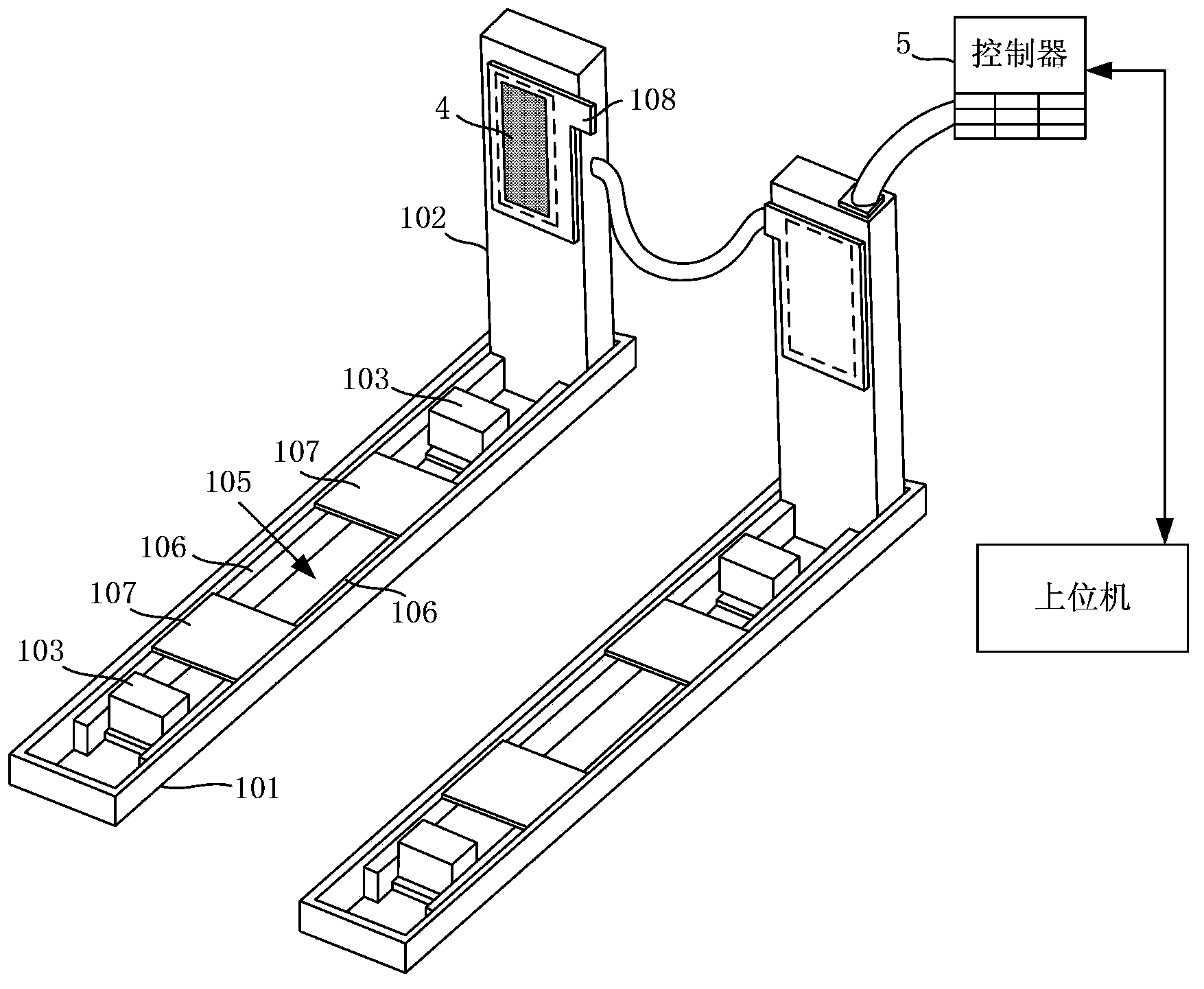

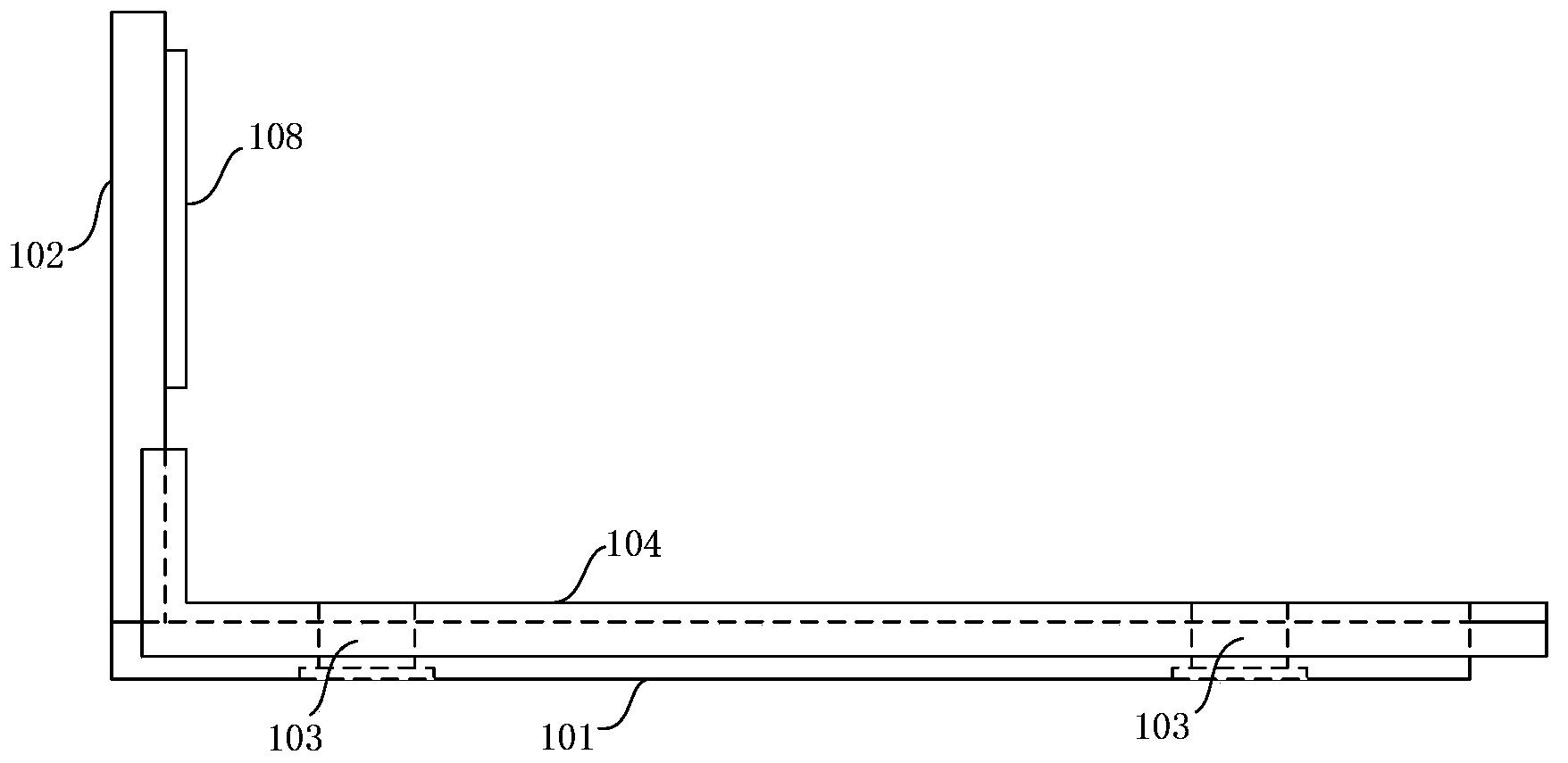

[0041] The present invention is used for the networked electronic weighing system of forklift, as figure 1 , figure 2As shown, it includes a left weighing frame 1, a right weighing frame 2, a load cell 3, a signal conditioning circuit 4, and a controller 5. Wherein, the left weighing frame 1 and the right weighing frame 2 have the same structure, and both include a weighing support 101, a circuit installation box 102, a load cell 103 and a loading plate 104; the length and width of the bottom surface of the weighing support 101 Not less than the length and width of the top surface of the pallet fork, and the top surface is axially provided with an installation groove 105 for installing the load cell 103 and serving as a wiring groove for the load cell 103 . The inside of the circuit installation box 102 is used to install the signal conditioning circuit 4, as well as con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com