Bi-circulating multistage anaerobic reaction device

An anaerobic reaction device and anaerobic reactor technology, applied in anaerobic digestion treatment, waste fuel and other directions, can solve the problems of high energy consumption of carrier flow, high system design requirements, low processing efficiency, etc., and achieve fast start-up speed , saving land, good water output effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

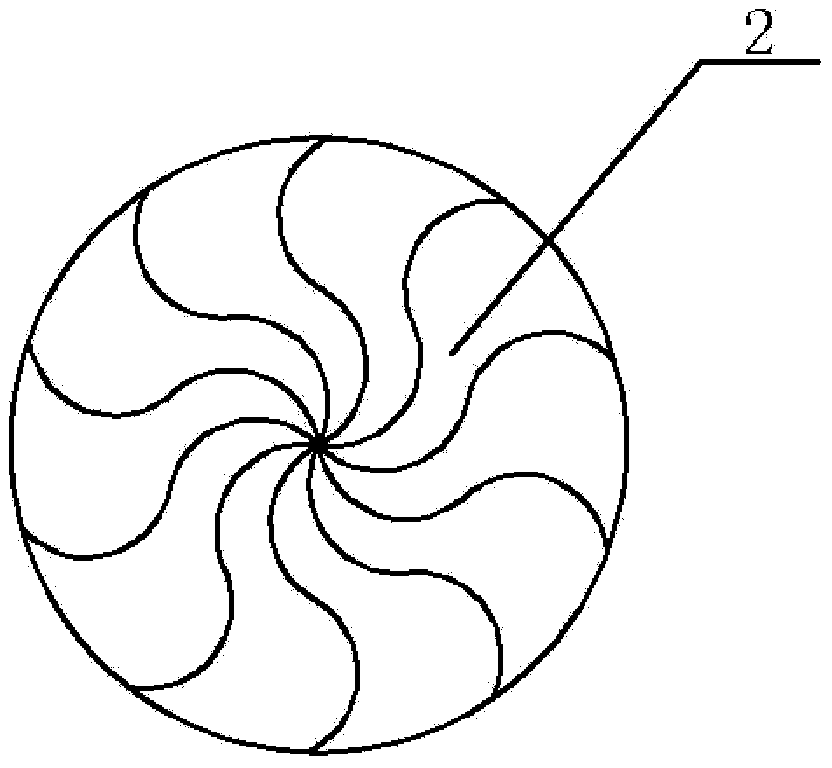

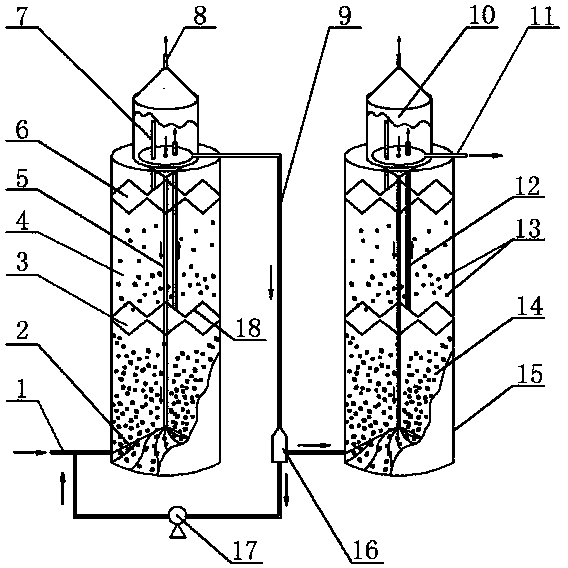

[0037] Such as figure 1As shown, a double-cycle multi-stage anaerobic reaction device includes a two-stage anaerobic reactor, and the anaerobic reactor includes a container body 15, and the container body 15 is sequentially provided with a water distributor 2 from bottom to top, leading to a distribution channel. The water inlet pipe 1 of the water tank 2, the first-level three-phase separator 3, the second-level three-phase separator 6, the outlet pipe 11 and the cyclone gas-liquid separator 10, and the top of the cyclone gas-liquid separator 10 is provided with a biogas outlet leading to the outside A fluidized bed reaction chamber 14 is provided between the pipe 8, the water distributor 2 and the primary three-phase separator 3, and a deep purification reaction chamber 4 is provided between the primary three-phase separator 3 and the secondary three-phase separator 6 , the upper cover of the first-level three-phase separator 3 is provided with a rising pipe 12 communicating...

Embodiment 2

[0039] The difference between this embodiment and Embodiment 1 is that the granular sludge 13 is elliptical with a long diameter of 0.5-3.0 mm; the primary three-phase separator 3 and the secondary three-phase separator 6 are composed of two rows of folding plates Composed in parallel, each row is provided with 10 folded plates 18, the top and bottom of the cyclone gas-liquid separator are conical, the conical surface and the plane form an angle of 60°, the rising pipe 12, the descending pipe 5 and the gas collecting pipe 7 The pipe diameter is 350mm.

Embodiment 3

[0041] The difference between this embodiment and Embodiment 1 is that the granular sludge 13 is spherical with a diameter of 0.5-2.0 mm and elliptical with a major diameter of 1.5-3.0 mm; the primary three-phase separator 3 and the secondary three-phase separator 6 are composed of two rows of folded plates 18 in parallel, and each row is provided with 15 folded plates 18. The top and bottom of the cyclone gas-liquid separator are conical, and the angle between the conical surface and the plane is 55°. The riser pipe 12 , The pipe diameters of downcomer 5 and air collecting pipe 7 are 200mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com