Repairing method of waste steel groove

A technology for steel scrap and steel plate, which is applied in the field of repairing damaged parts of scrap steel troughs used in converters, can solve the problems of steelmaking production constraints on the turnover of scrap steel troughs, leakage of small scrap steel, and increased production costs, etc., and achieves a simple and easy repair method, The effect of increasing the number of turnover and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The concrete steps of scrap steel channel repairing method of the present invention are:

[0023] 1. Carry out sizing repair on the damaged part:

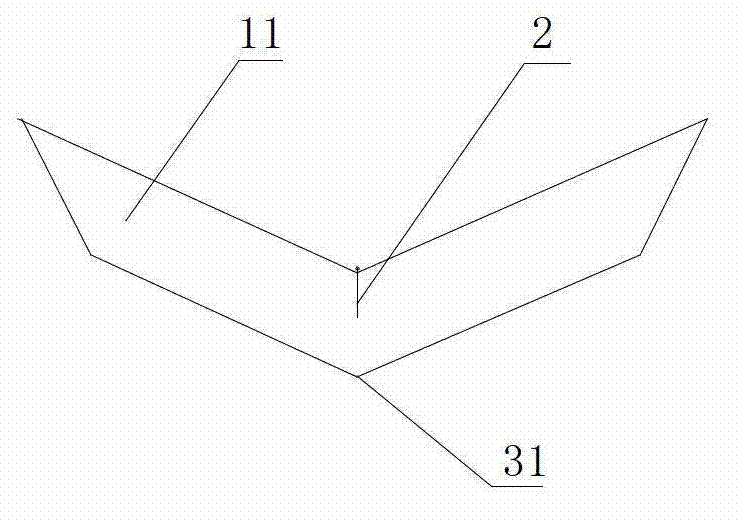

[0024] Based on the principle of minimization, use oxygen or acetylene to cut a regular-shaped notch on the damaged part, and cut and chamfer the edges of the notch to form a "trapezoidal" notch with a large inner opening and a smaller outer opening.

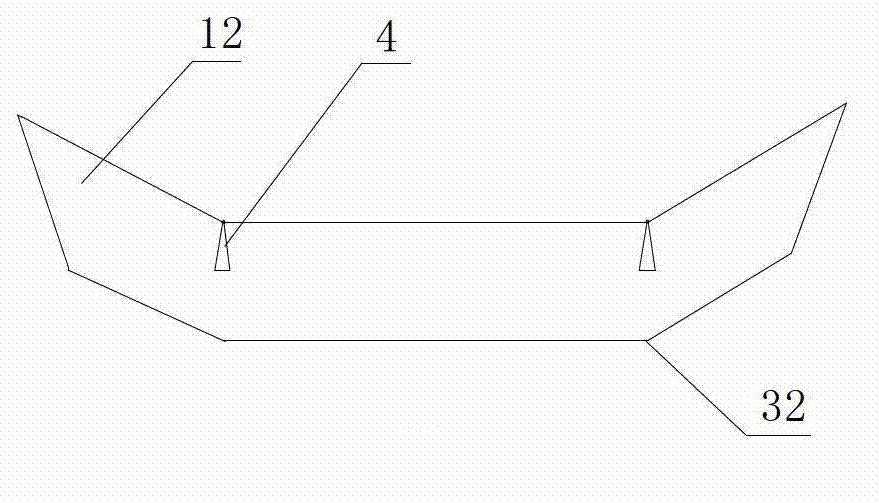

[0025] 2. Patch preparation:

[0026] If the damaged part is on the groove wall or edge, find a flat steel plate with the same thickness as the groove wall, and cut out a steel plate of the same size but opposite to the chamfering direction according to the size of the cut "trapezoidal" notch and the slope of the chamfer. "Inverted Trapezoidal" patch.

[0027] If the damaged part is at the bottom of the curved scrap steel groove, find a steel plate with the same or similar thickness and radian as the bottom of the groove, and cut out a steel plate of the same size, But "inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com