A method for relining of rotary kiln

A technology of rotary kiln and lining, which is applied in the direction of rotary drum furnace, lining repair, furnace, etc., can solve the problems of long maintenance time and affect normal production, and achieve the effect of low cost, shortened maintenance time and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

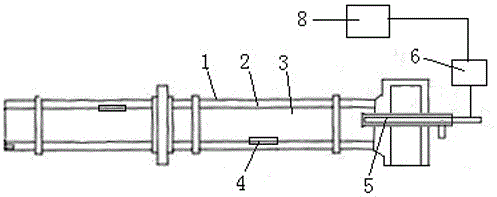

[0021] The method for repairing the inner lining of the rotary kiln of the present invention, the rotary kiln is as figure 1 Shown is composed of a furnace wall and a lining 2, the center of the lining is the kiln chamber 3, and the steps of filling the lining are as follows:

[0022] (1) Use an infrared camera to detect the damage of the inner lining of the rotary kiln 1, and determine the damaged area and degree of damage of the damaged part 4 of the inner lining;

[0023] ⑵Prepare the raw material limestone and equipment 8 for repairing the furnace, connect the raw material equipment for repairing the furnace with the fuel system 6 of the rotary kiln, and connect the fuel system to the burner; add the repairing additive to the raw material for repairing the furnace, which is a water reducer , so that the liquid ash can be in good contact with the damaged surface of the inner lining and blend into one;

[0024] (3) Add furnace repair raw materials to the fuel system through...

Embodiment 2

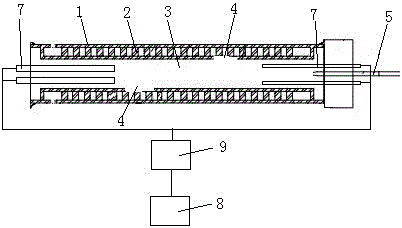

[0029] Another embodiment of the present invention is as figure 2 As shown, the rotary kiln is a rotary kiln with a partition wall, and the raw material for repairing the furnace is a mixture of silica or alumina powder, and the mass ratio of the two is 1:1. The lining of the kiln body is a hollow structure composed of a refractory inner cylinder made of refractory materials and a refractory outer cylinder made of refractory materials. The center of the refractory inner cylinder is the kiln chamber. It is a material channel, and the material channel is provided with refractory supports.

[0030] The rotary kiln is equipped with conveying and spraying equipment 9, and two repairing guns 7 are respectively inserted into the rotary kiln or both ends thereof, and the material of the repairing guns is ceramics. The furnace repair raw material equipment is connected with the conveying and spraying equipment, and the conveying and spraying equipment is connected with the furnace re...

Embodiment 3

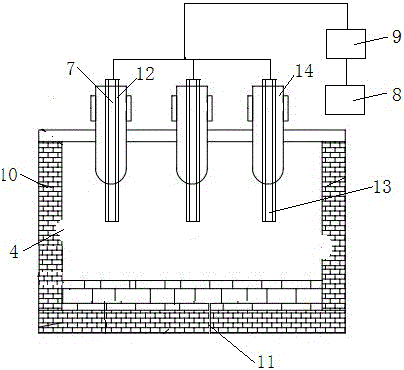

[0032] Another embodiment of the present invention is as image 3 As shown, the DC arc calcium carbide furnace includes a furnace cover, a furnace shell and a furnace bottom. A hollow electrode 14 is inserted on the furnace cover, and a furnace bottom electrode 11 is inserted at the bottom. The calcium carbide furnace is provided with conveying and spraying equipment 9 and a repairing gun 7, and the repairing gun is a steel repairing gun with a cooling chamber 12. The furnace repairing gun 7 is inserted and passed through the hollow electrode, and the furnace repairing gun protruding from the electrode part 13 can turn the direction. The end of the repairing gun is provided with a plasma burner for heating the raw materials for repairing the furnace. The furnace repair raw material equipment is connected with the conveying and spraying equipment, the conveying and spraying equipment is connected with the furnace repairing gun, and the furnace repairing gun is inserted into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com