Electrolytic polishing device

An electrolytic polishing and electrolyte technology, applied in the direction of electrolytic process, electrolytic components, etc., can solve the problems of unfavorable high-efficiency, stable and continuous production requirements, can not meet the industrial production, affect the surface quality of workpieces, etc., to reduce production intermittent time, Effects of improving efficiency and widening the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

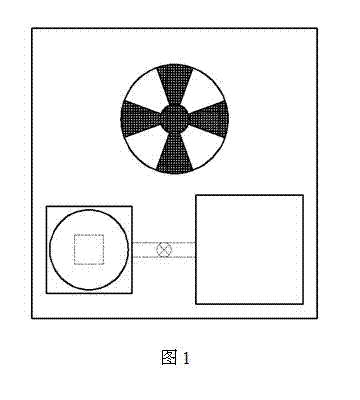

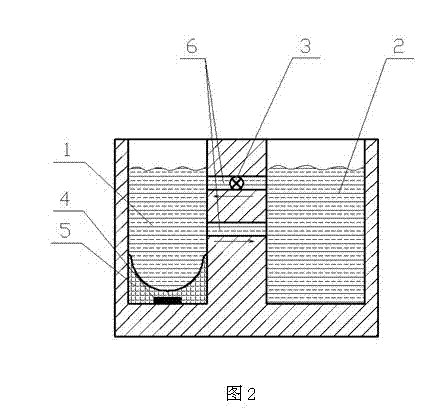

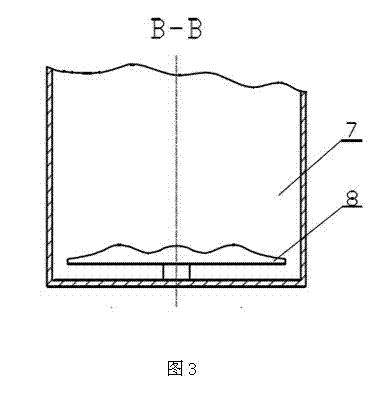

[0016] Such as figure 1 , figure 2 , image 3 The electropolishing device shown is composed of a cathodic electrolytic tank 1, an electrolyte storage tank 2, a cleaning tank 7, an acid-resistant pump 3, a connecting pipe 6, a cathode plate 4 and a solid arc cathode 5. The cathodic electrolyzer 1 is communicated with the electrolyte storage tank 2 through a connecting pipe 6, and an acid-resistant pump 3 is installed in the middle of the connecting pipe at the upper end. The cathode plate 4 is connected to the negative pole of the power supply and placed at the bottom of the cathode electrolytic tank 1 . The bottom of the actual matching arc-shaped cathode 5 is in close contact with the cathode plate 4 . A wave wheel 8 is equipped with at the bottom of the cleaning tank 7 .

[0017] In the electropolishing device, there are two connecting pipelines, one placed in the lower part of the cathodic electrolytic cell 1 and the electrolyte storage tank 2;

[0018] In the electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com