High-precision detonator blasting system based on electronic delay body

A delayed and high-precision technology, which is applied in blasting, electric fuzes, weapon accessories, etc., can solve the problems of complex and redundant systems, and achieve the effects of ensuring high-precision time delays, streamlined and reliable systems, and eliminating chemical pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

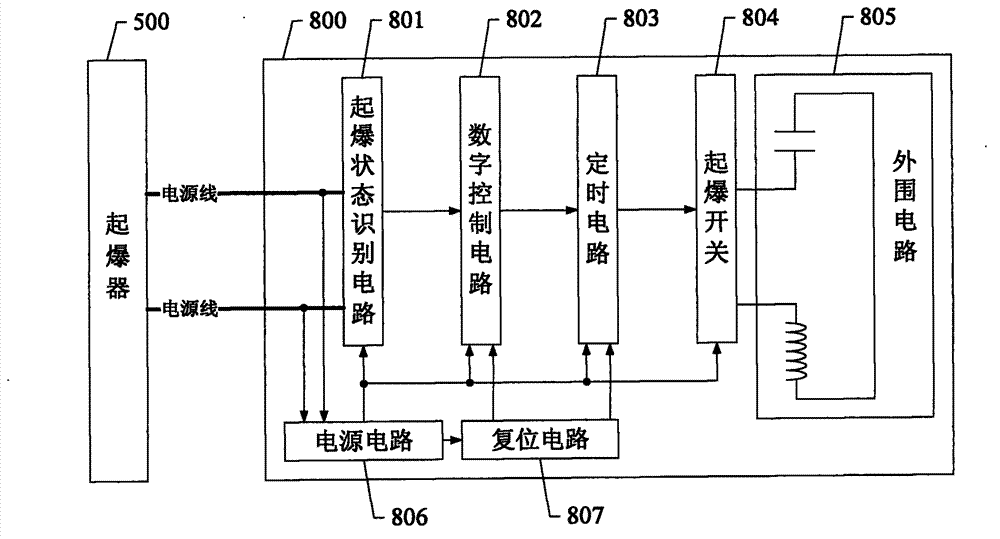

[0023] Such as figure 1 Shown is a block diagram of the basic composition of the detonator blasting system of the present invention. The high-precision detonator blasting system based on the electronic delay body includes a detonator 500 and an electronic delay body detonator 800 connected through a power line. The electronic delay detonator 800 includes a timing circuit 803, a detonation state identification circuit 801, a digital control circuit 802, a detonation switch 804, a power supply circuit 806, a reset circuit 807, an energy storage capacitor and a peripheral circuit 805 composed of bridge wires. The timing circuit 803 is connected to the digital control circuit 802 at one end and to the detonation switch 804 at the other end. The timing circuit 803 includes an OSC oscillator with a main frequency of 32.768kHz. After laser calibration, the accuracy can reach 99%. The OSC oscillator provides a clock reference for the timing circuit 803 and the digital control circuit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com