Sub-aperture splicing interferometer system and method for measuring surface shape of optical lens

A technology of sub-aperture splicing and aperture splicing, which is applied in the field of optical detection, can solve the problems of air-film fluctuations in the air-floating guide, affecting the repeatability and measurement accuracy of the measurement, and the influence of the phase-shifting accuracy of the laser interferometer, and achieves absolute measurement, The effect of reducing airflow and temperature fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

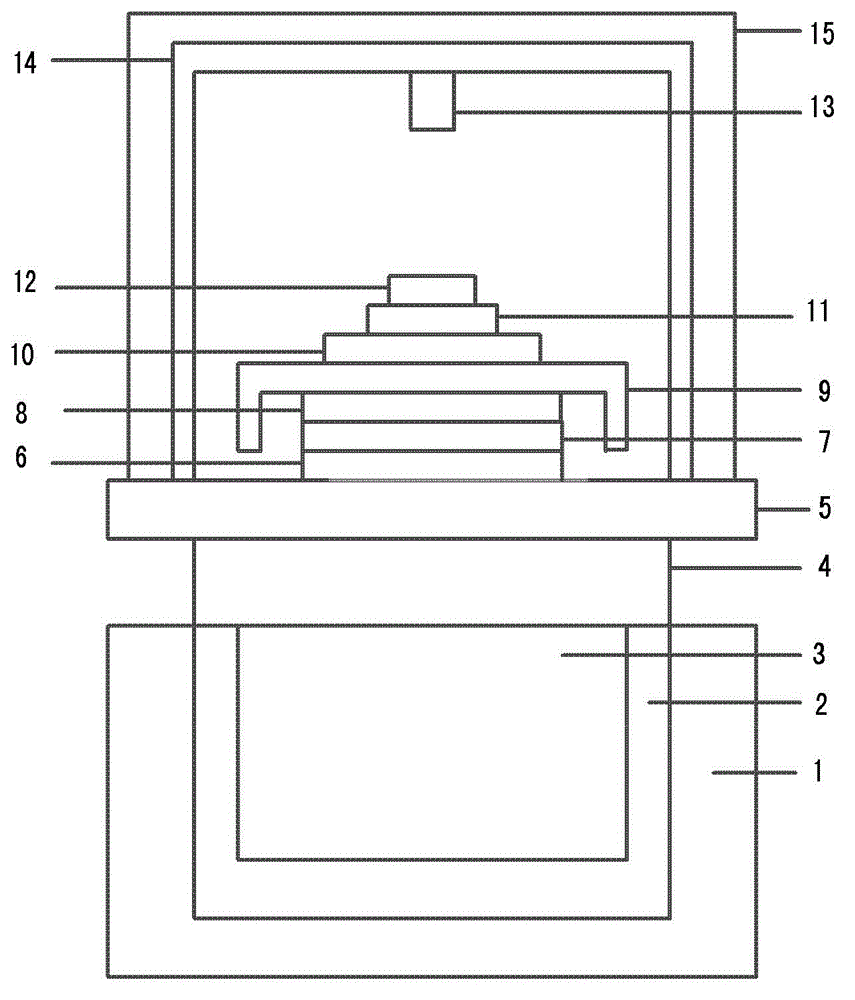

[0048] Such as figure 1 It shows the structural diagram of the device of the present invention, consisting of a ground vibration isolation unit 1, a partition layer 2, a filler 3, a first active vibration isolation unit 4, a platform 5, an air-floating guide rail 6, a first platform 7, and a second active vibration isolation unit 8. The second platform 9, the moving mechanism 10, the turntable 11, the optical lens to be tested 12, the laser interferometer 13, the truss frame 14, and the transparent cover 15. in:

[0049] An isolation layer 2 is placed in the pit of the ground vibration isolation unit 1, and the isolation layer 2 is used to isolate the surrounding underground materials;

[0050] A filler 3 is placed in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com