Automatic optic detecting system and method

A technology of automatic optical inspection and inspection platform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In order to understand the present invention more clearly, describe the present invention in detail in conjunction with accompanying drawing and embodiment:

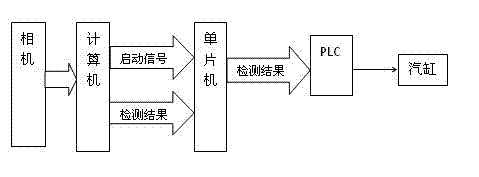

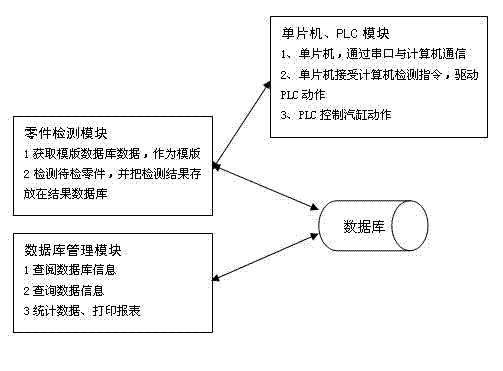

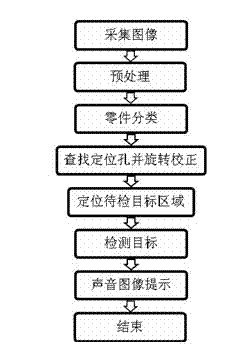

[0057] Such as Figure 1 to Figure 16 As shown, the automatic optical detection system includes a mechanical system and a control system. The mechanical system is mainly composed of a bracket 1, a detection platform 2, an image acquisition box 3, a cylinder positioning component 4 and a workpiece pallet 5;

[0058] The control system is mainly composed of image acquisition components, light source controller, LED light source, single-chip microcomputer, PLC module and computer;

[0059] Bracket 1 is used as the base frame supporting detection platform 2 and cylinder positioning assembly 4. The detection platform 2 is fixed on the bracket 1. A rectangular opening is processed on the detection platform 2. A ball sliding platform 6 is installed on the opening, and the ball sliding platform 6 is used for the workpiece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com