Anti-disaster optical cable

An optical cable and optical fiber technology, applied in the optical field, can solve the problems of inconvenient optical cable, insufficient tensile force and lateral pressure resistance, heavy weight, etc., and achieve the effects of convenient construction, rapid network construction, and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

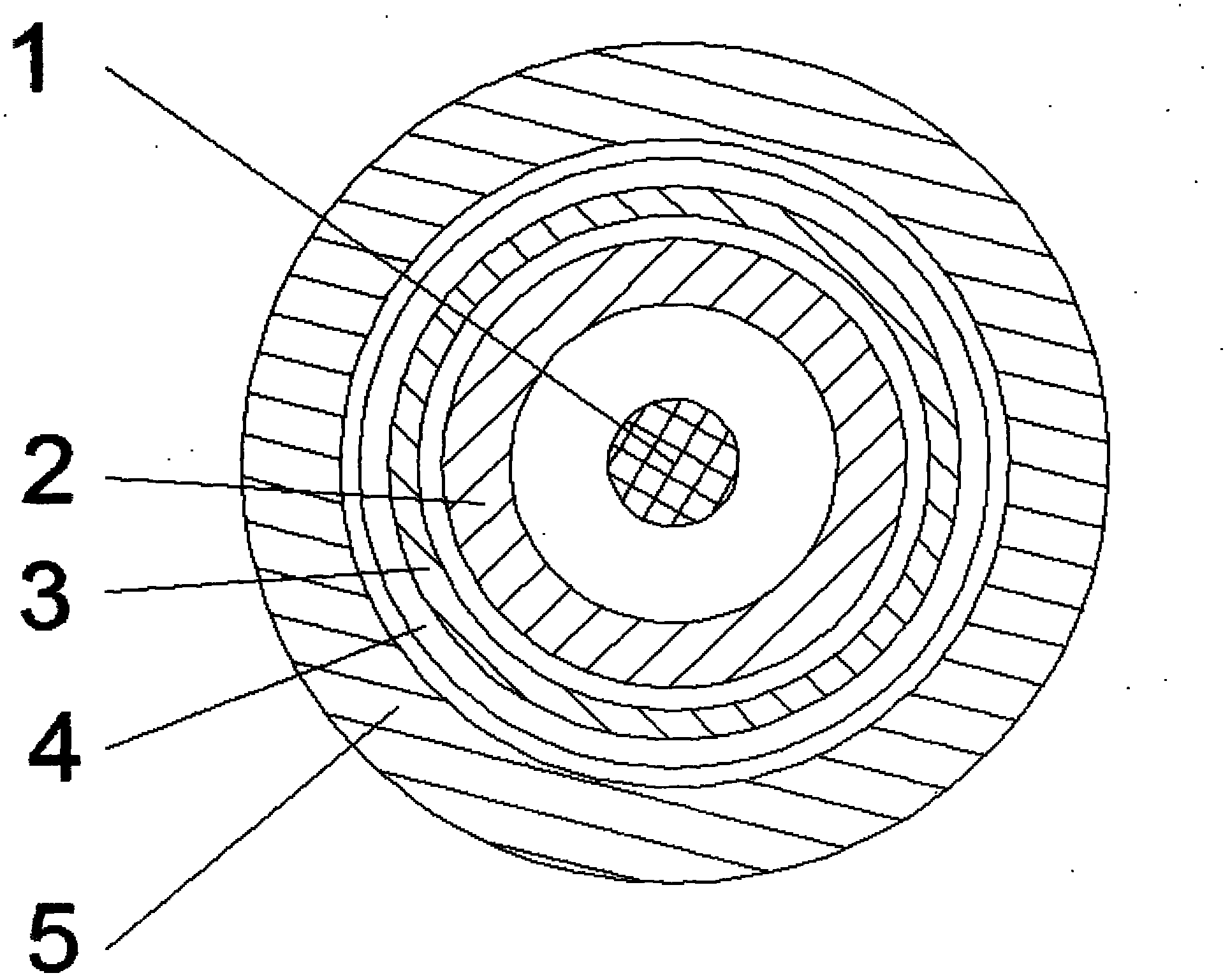

[0015] as attached figure 1 The shown disaster-resistant optical cable of the present invention includes a communication optical fiber 1, a metal hose 2, an aramid fiber layer 3, a metal braid 4, and an outer sheath 5 of the optical cable; the metal hose 2 wraps the communication optical fiber 1 The aramid fiber layer 3 wraps the metal hose 2; the metal braided mesh 4 wraps the aramid fiber layer 3; the optical cable outer sheath 5 wraps the metal braided mesh 4; the communication optical fiber 1 is 1 core to 166 cores; the metal hose 2 is made of stainless steel wire or special steel wire, and the metal hose is a metal spiral tube or a metal seamless tube or a metal nodular tube; the spiral tube is a single layer or a double layer Stranding, the double-layer twisting is double-layer twisting in the same direction or reverse double-layer twisting; the aramid fiber layer 3 is formed by using a kind of aromatic polyamide fiber in parallel or mesh weaving; The metal braid 4 is b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com