Combined adjustable transformer bobbin and transformer applying same

A transformer skeleton, combined technology, applied in transformer/inductor parts, transformer/inductor coil/winding/connection, electrical components, etc., can solve the problem of reducing the overall volume of the transformer, increasing the material cost, and long operating time, etc. problems, to achieve the effect of reducing the difficulty of the production process, increasing the electrical clearance, and expanding the layout space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

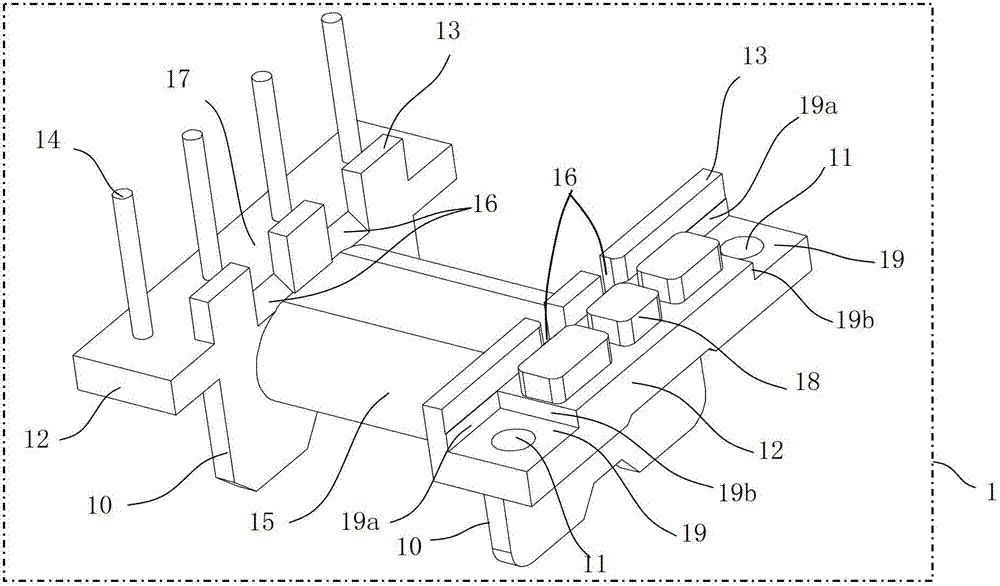

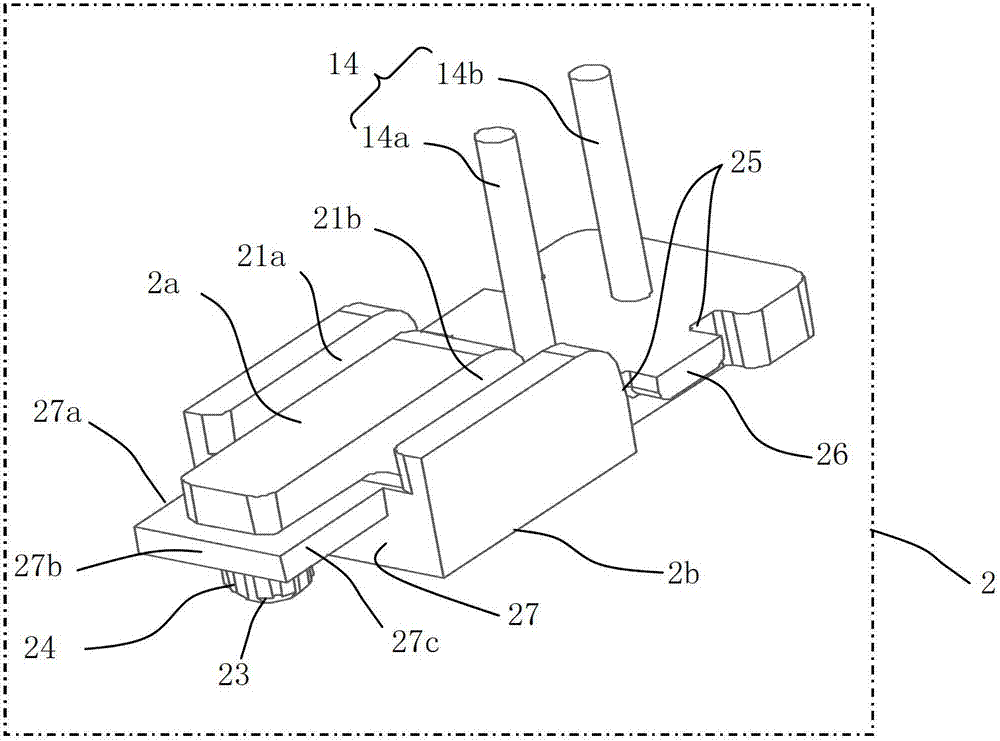

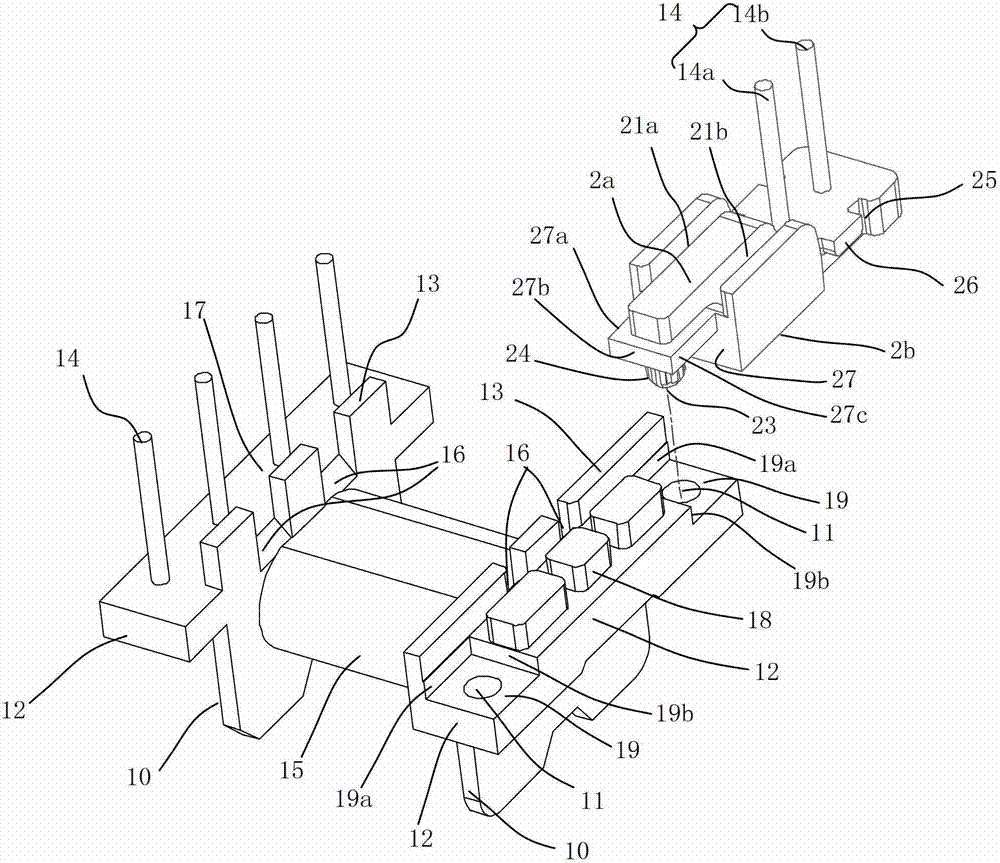

[0035] Such as Figure 1-7As shown, it is a combined adjustable transformer skeleton of the present invention, including a frame body, which is mainly composed of a main frame 1 and at least one connector 2. The main frame 1 includes a cylindrical winding part 15 and a horizontally arranged The wiring part and the socket at both ends of the winding part are the winding carrier of the transformer. The elongated horizontal support plate 12 supporting the magnetic core 4, the wiring part also includes at least one metal winding terminal 14 vertically arranged on the lower surface 17 of the support plate 12. In this embodiment, there are 4 winding terminals along the supporting plate. The longitudinal arrangement of the board 12; the plug connector 2 is mainly composed of an elongated horizontal mounting plate and a winding terminal 14 vertically arranged on the lower surface of one end of the mounting plate. There is at least one winding terminal. There are two wire terminals, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com