Solar battery and method for splicing solar battery fragments

A technology for solar cells and fragments, applied in the field of solar cells, can solve the problems of unutilized battery fragments, smaller battery area, smaller current, etc., and achieve the effects of improving utilization rate, reducing series resistance and avoiding waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

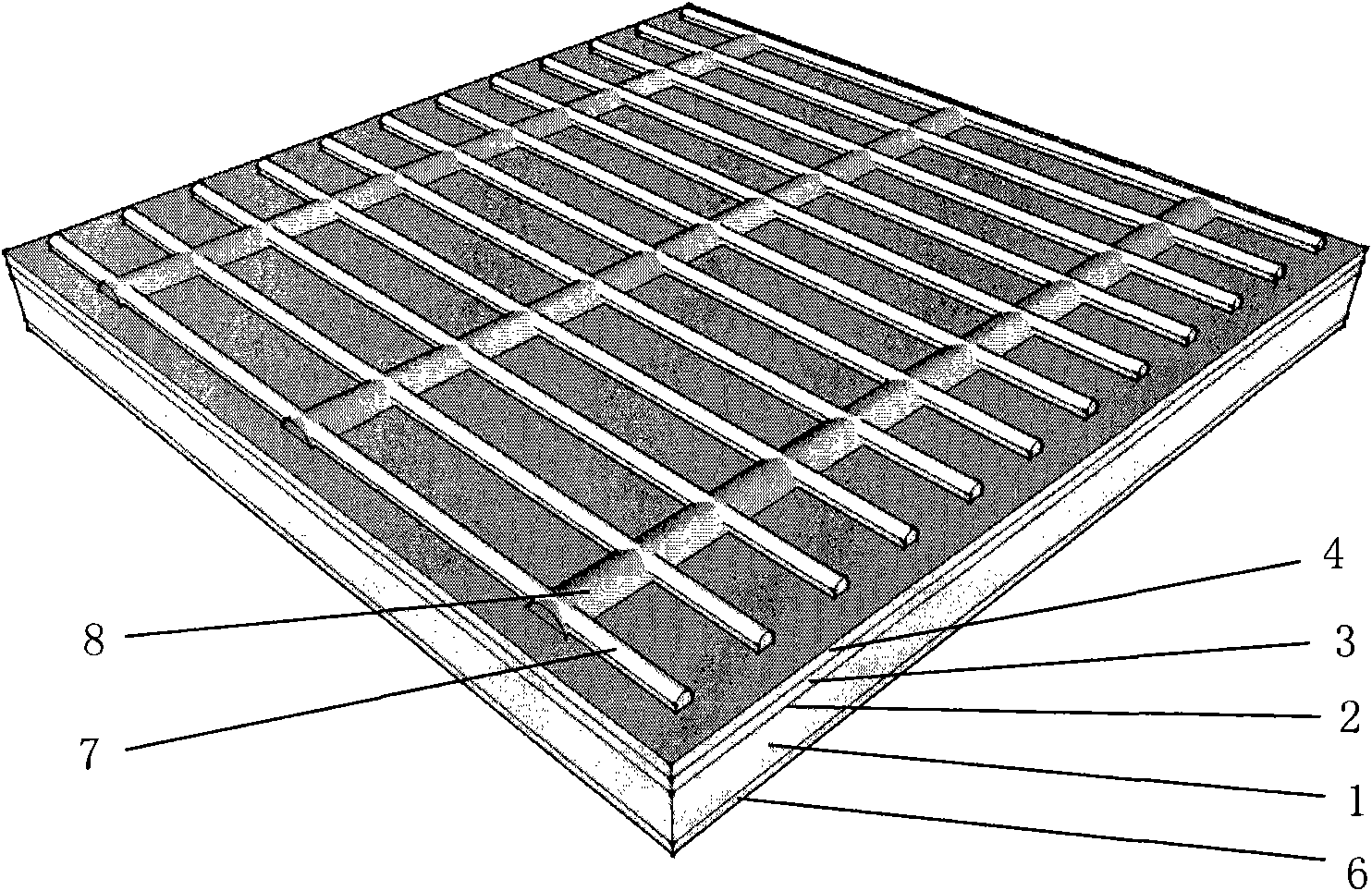

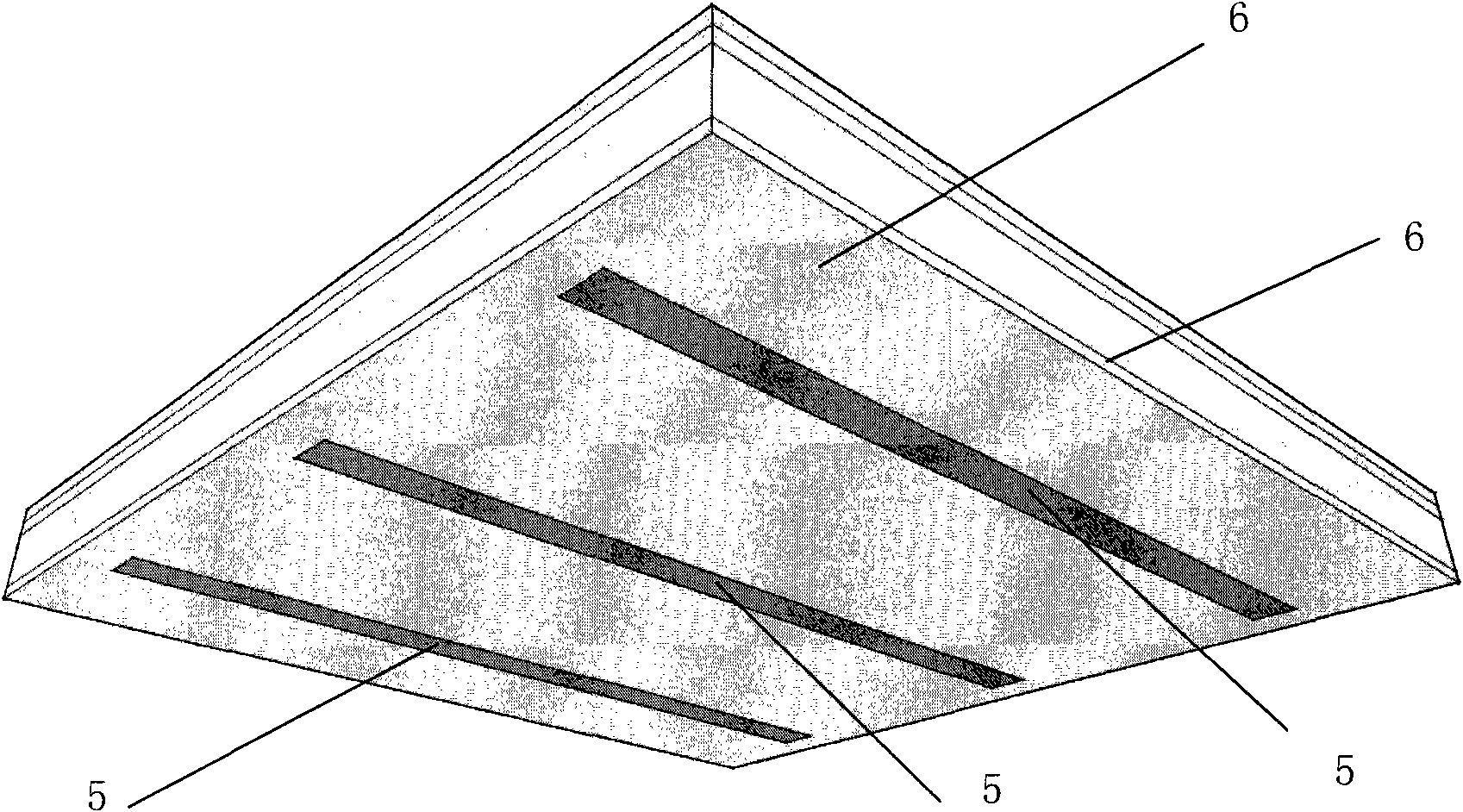

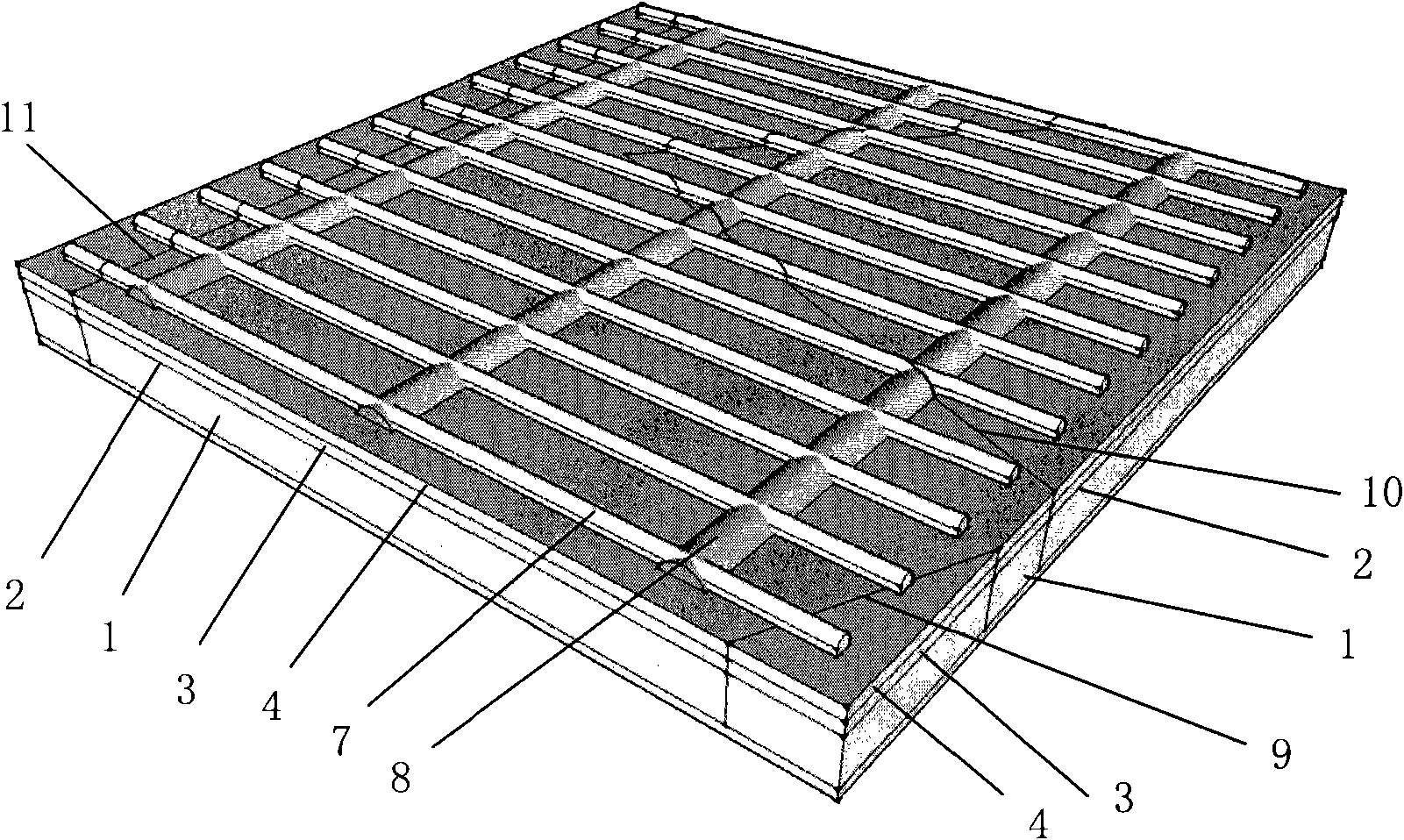

example 1

[0109] Electrical interconnection mode 1, that is, the transmission area or the base area connection, the following only uses the transmission area connection as an example for illustration. Such as Figure 3-1 As shown, the emission area connection is to use the material used as the emission area connection wire 13 and the emission area wire bridge connection point 14, and through a suitable process, the two sides of the emission area that are electrically isolated due to cracks or fractures will be electrically connected again, so that the current From the emission area on one side of the crack to the emission area on the other side of the crack through the wire. The connecting wire 13 in the emitter area can be made of metals such as silver, copper, tin, or an alloy of silver, copper, tin, or other metals, or a wire coated with these metals or alloys. In the present invention, the connecting wire 13 in the emission area only needs to be a conductive wire. The connection p...

example 2

[0111] Electrical interconnection mode 2, that is, the connection of the front electrode line: the emission area that is electrically isolated by the crack or the fracture can also be connected to the front electrodes on both sides of the crack or the fracture to re-realize the electrical interconnection of the emission areas on both sides. This crack repair method is called front electrode wire connection. Such as Figure 3-2 As shown, cracks or cracks can cause the interruption of the current path in the front electrode finger grid 7 and the front electrode main grid 8, and the front electrode connection line 15 is placed on the surface of the front electrode finger grid 7 and the front electrode main grid 8, and then The two ends of the front electrode connection line 15 are welded together with the front electrode by means of hot pressing, laser or ultrasonic waves to form the connection point 16 of the front electrode line. After repairing this process, the passage of the...

example 3

[0113] Electrical interconnection method 3, that is, the local network connection of the front electrode: use a metal mesh with the same area and shape as the crack in the plane direction of the solar cell to cover the area with cracks or fractures, make the metal mesh contact with the front electrode, and then use hot pressing , laser or ultrasonic and other welding methods, so that the metal mesh and the front electrode finger grid 7 and the front electrode main grid 8 form a good electrical contact, thereby eliminating the impact of cracks or cracks on the front electrode of the solar cell. The material of the partial net can be metals such as silver, copper, tin, etc., or an alloy of silver, copper, tin, or other metals, or a material coated with these metals or alloys on the periphery. The spacing between the parallel mesh stripes can be the same as that of the front electrode finger grid 7 of the solar cell to be repaired, or it can be different. Such as Figure 3-3 , p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com