High-gain omnidirectional antenna

An omnidirectional antenna and high-gain technology, applied in antennas, resonant antennas, electrical components, etc., can solve the problems of cumbersome assembly process, poor consistency, and low reliability, and achieve good symmetry, facilitate mass production, and high reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

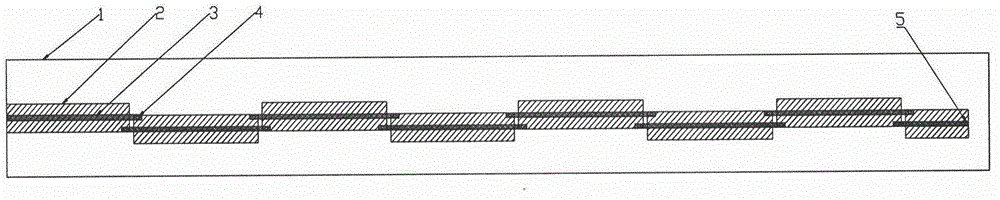

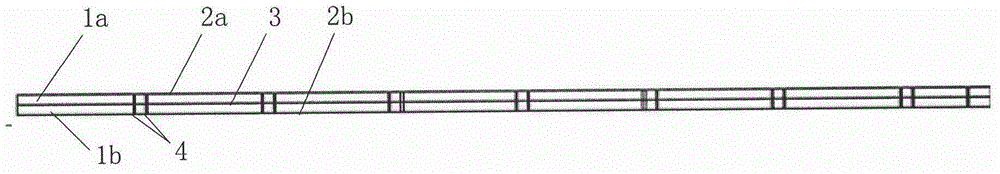

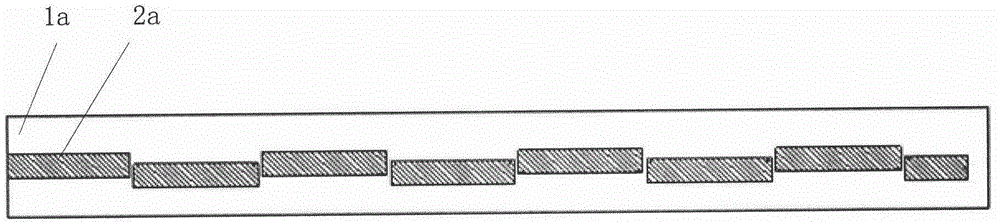

[0020] As shown in Figures 1 and 2, the high-gain omnidirectional antenna of the present invention includes a microwave dielectric substrate 1 and a multi-section microstrip line, wherein the microwave dielectric substrate 1 is composed of an upper microwave dielectric substrate 1a and a lower microwave dielectric substrate The composition of 1b is to print multi-section alternately fed striplines on the microwave dielectric substrate 1 by using a printed circuit board process. Increasing the number of stripline sections increases antenna gain.

[0021] Each section of the stripline is composed of an upper metal grounding plate 2a, a lower metal grounding plate 2b and a metal conductive strip 3 sandwiched between two layers of microwave dielectric substrates. The upper metal ground plate 2a is printed on the upper surface of the upper micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com