Crushing type blockage prevention device

An anti-clogging and crushing technology, applied in grain processing, etc., can solve the problems of large temperature difference loss of water source, high operating cost, incomplete filtration, etc., and achieve the effect of low operating cost, simple process and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

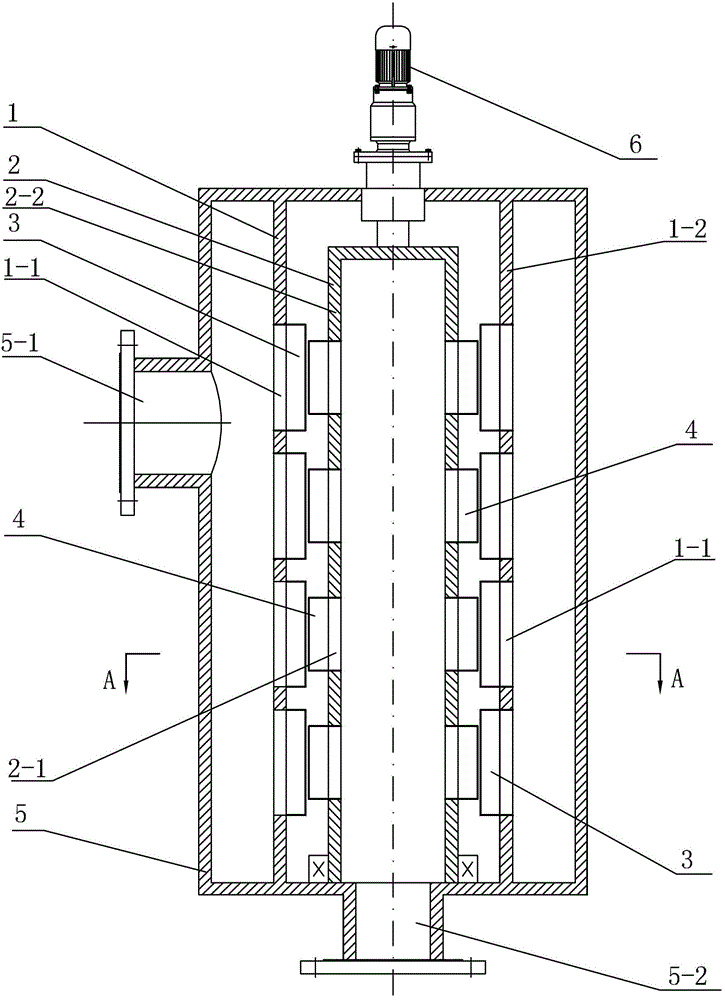

[0008] Specific implementation mode one: combine Figure 1 to Figure 5 Describe this embodiment, a crushing anti-clogging device of this embodiment includes a fixed outer cylinder 1, a rotating inner cylinder 2, an outer shell cylinder 5, a drive device 6, a plurality of inner blades 4 and a number of inner blades 4 consistent with A plurality of outer blades 3, the rotating inner cylinder 2 and the fixed outer cylinder 1 are respectively arranged in the shell cylinder 5, the fixed outer cylinder 1 is set outside the rotating inner cylinder 2, the fixed outer cylinder 1 is connected with the shell cylinder 5, and the shell cylinder 5. The fixed outer cylinder 1 and the rotating inner cylinder 2 are arranged coaxially. A driving device 6 is provided on the upper end surface of the shell cylinder 5. The driving end of the driving device 6 is connected with the rotating inner cylinder 2. The driving device 6 is used to drive the rotating inner cylinder. When the cylinder 2 rotate...

specific Embodiment approach 2

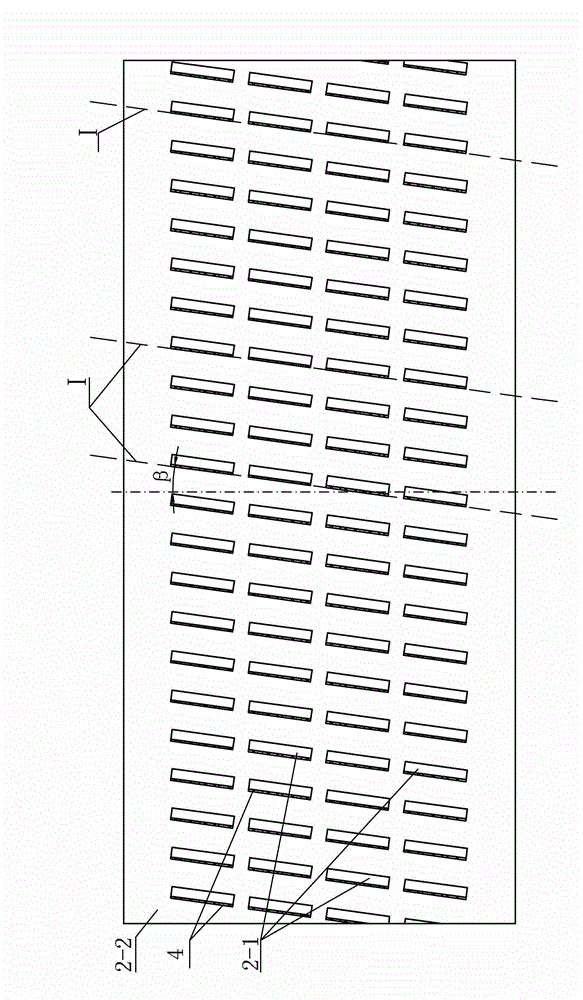

[0009] Specific implementation mode two: combination figure 2 and image 3 This embodiment will be described. The deployed inner blades 4 and outer blades 3 in this embodiment are all rectangular blades. In this way, the inner blade 4 and the outer blade 3 are arranged in cooperation to cut the large-grained dirt and sundries in the water, and break them into small-sized dirt, so that they can enter heat exchange equipment, heat pump units, refrigeration units and other equipment to meet The system is not required to be blocked and improves the treatment effect. Others are the same as in the first embodiment.

specific Embodiment approach 3

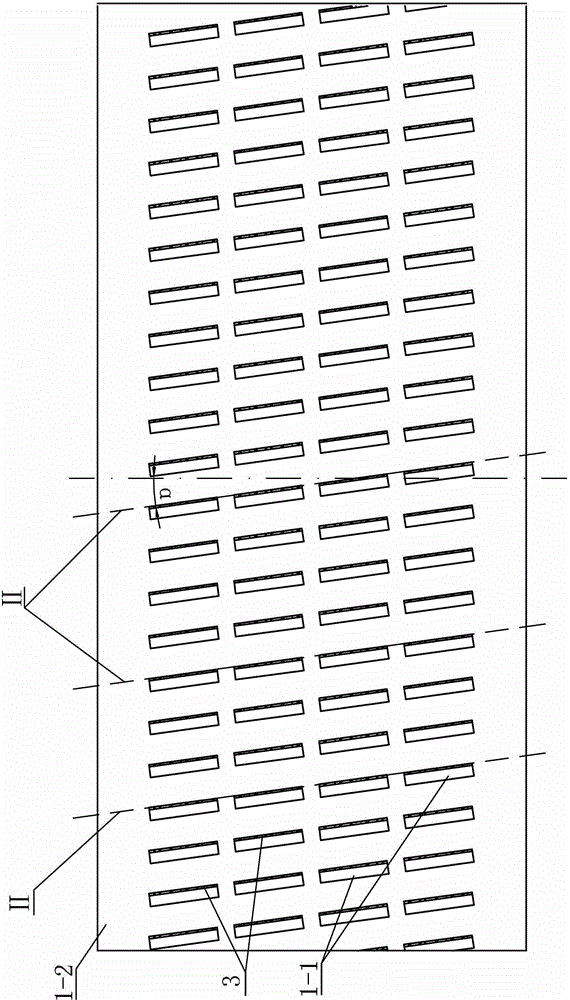

[0010] Specific implementation mode three: combination Figure 5 This embodiment will be described. The deployed inner blades 4 and outer blades 3 in this embodiment are all wedge-shaped blades. In this way, the inner blade 4 and the outer blade 3 are arranged in cooperation to cut the large-grained dirt and sundries in the water, and break them into small-sized dirt, so that they can enter heat exchange equipment, heat pump units, refrigeration units and other equipment to meet The system is not required to be blocked and improves the treatment effect. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com