Electrostatic dust collector used in converter gas dry dust collection system

An electrostatic precipitator and dry dust removal technology, applied in the field of electrostatic precipitators, can solve problems such as the complexity of the precipitator, and achieve the effects of saving space, avoiding hazards and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

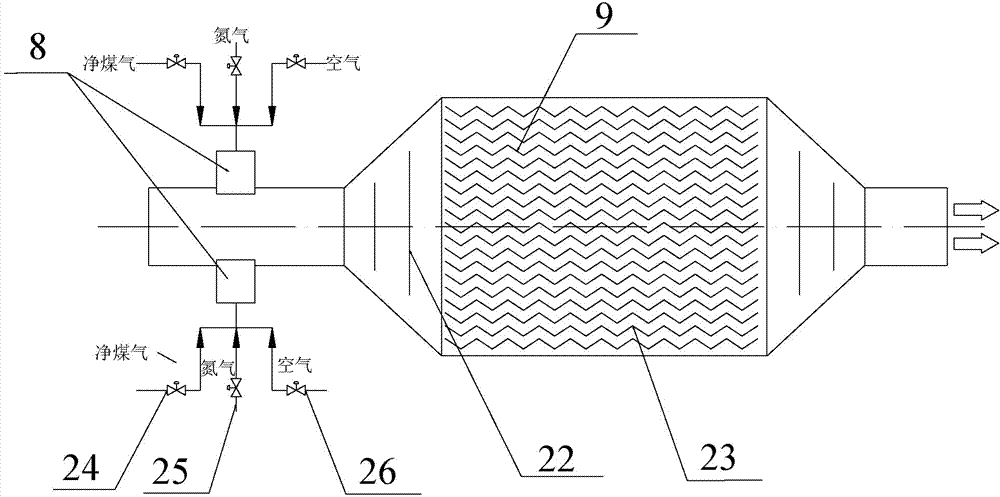

[0014] The main components of converter gas dry dedusting system are converter, vaporization cooling flue, steam drum, gas-liquid two-phase spray gun, evaporative cooler, coarse ash collection system and electrostatic precipitator. The vaporization cooling flue is mainly to reduce the temperature of the gas to generate saturated water vapor, which is separated and collected by the steam drum. It is a converter gas waste heat recovery device; the evaporative cooler lowers the gas temperature by spraying water from the gas-liquid two-phase spray gun, and passes through the bottom of the evaporative cooler. The connected coarse ash collection system coarsely removes dust to the coarse ash bin and adjusts the dielectric constant of the dust, and realizes fine dust removal through the electrostatic precipitator system, etc.

[0015] As shown in Fig. 1, it is an embodiment of the electrostatic precipitator used in the converter gas dry dust removal system according to the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com