High-speed transverse-swing feeding conveying belt feeding shoe magnet automatic chamfering grinding machine

A conveyor belt and swaying technology, which is applied in the field of tile-shaped magnet automatic chamfering grinders, can solve the problems of stability (poor synchronization, slow feeding speed, product or equipment damage, etc.), achieve stable and reliable work, improve production efficiency, and system good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

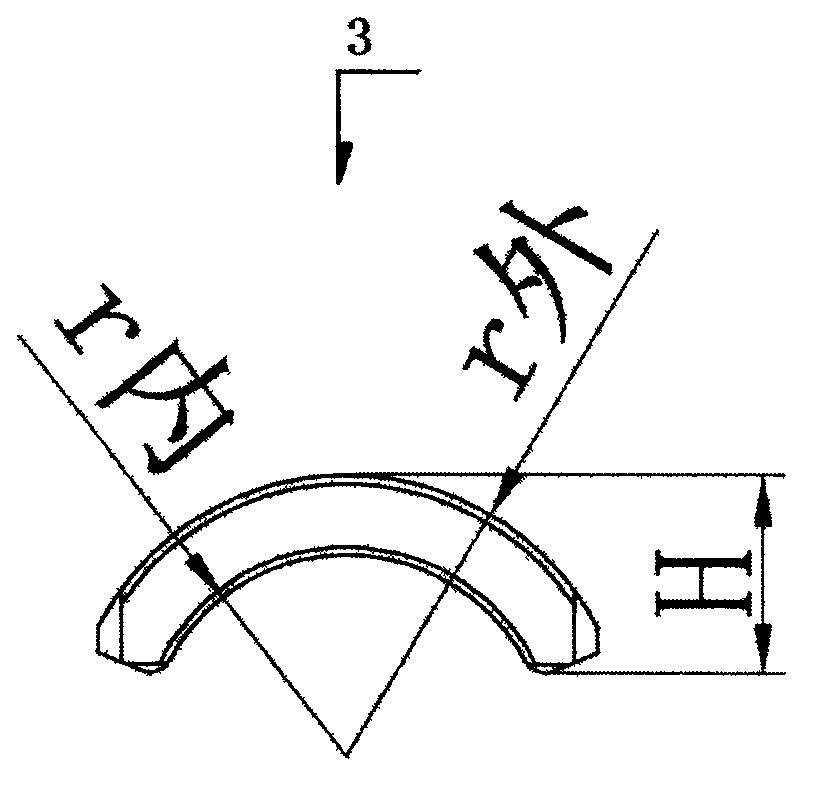

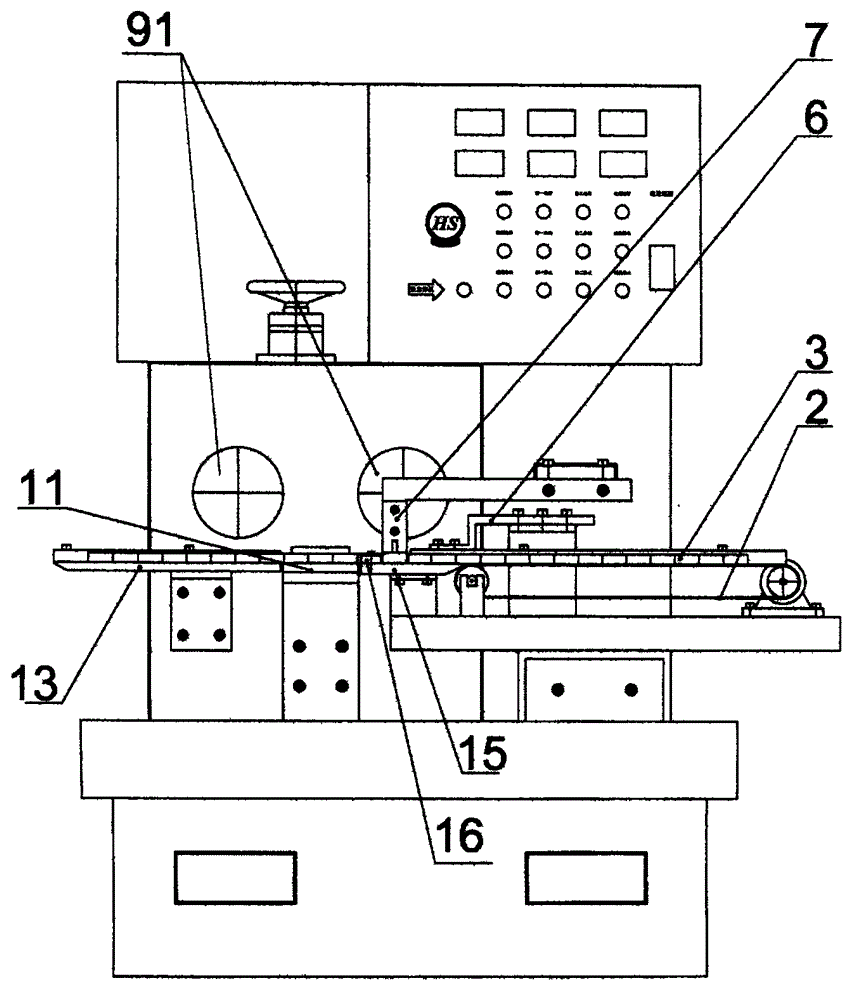

[0024] exist image 3 and Figure 5 Middle: The magnetic tile 3 from the pre-processing equipment is sent to the conveyor belt 2, and the magnetic tile 3 is transferred to the transition plate 15 under the drive of the conveyor belt 2 and continues to move to the left. The magnetic tile 3 is received by the tail of the transition plate 15 The magnetic tile limit block 16 is limited and stops moving, and the shifting block 7 performs periodic yaw motion to make the magnetic tile 3 swing inward to the feeding position (at this time, the push rod 6 is in the retreat gap), when the magnetic tile 3 is in place, the push rod 6 is just in the forward state, and the magnetic tile 3 is pushed to the left to move the magnetic tile 3 to the chamfering tooling 11, and the chamfering tooling 11 moves up and down periodically, and the magnetic tile 3 on it is raised to At the proper position, let the rotating grinding wheel 91 chamfer the outer arc end surface of the magnetic tile 3 (simil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com