Airship tail vectored thrust device

A vector thrust and thrust device technology, which is applied in aircraft, rigid spacecraft, transportation and packaging, etc., can solve the problems of long control arm of the empennage, difficulty in overcoming airship head-up/down moment, and difficulty in attitude adjustment, so as to increase flight Speed, improve environmental adaptability, increase the effect of control torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

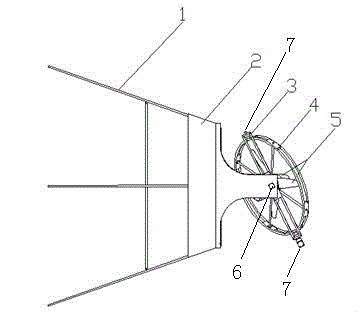

[0012] see figure 1 , the airship tail vector thrust device includes a tail cone 1 with a two-degree-of-freedom turntable base 2 at the rear end; the two-degree-of-freedom turntable base 2 is connected to the turntable controller; the Z-axis rotating body 3 passes through the A screw shaft 6 at both ends Installed on the two-degree-of-freedom turntable base 2, the Z-axis rotating body 3 can deflect ±90° in the vertical plane around the A helical axis 6; the Y-axis rotating body 4 is installed on the Z-axis rotating body 3 through the B helical shaft 7 at both ends Above, the Y-axis rotating body 4 can deflect ±90° in the horizontal plane around the B screw axis 7; the Y-axis rotating body 4 is equipped with a thrust device 5; the thrust device 5 is connected to the thrust device controller.

[0013] Wherein, the tail cone 1 is a circular platform structure, the front end of the tail cone 1 is connected to the tail of the airship capsule through a buckle and a tension wire, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com