Sterilizing type coking wastewater advanced treatment process and sterilizing type coking wastewater advanced treatment device

A technology for coking wastewater and advanced treatment, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. problems, to achieve the effect of strong engineering application value, reasonable equipment design, and simple equipment operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

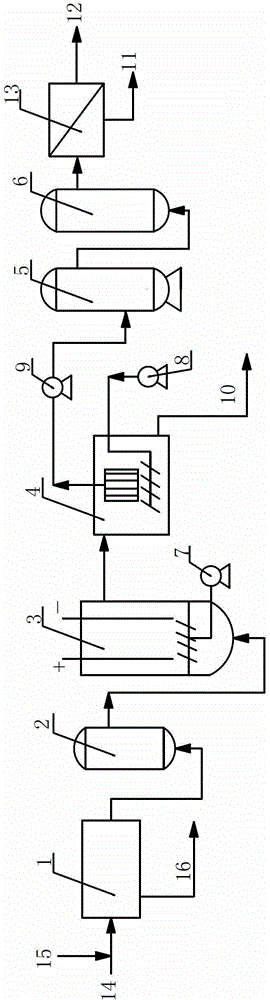

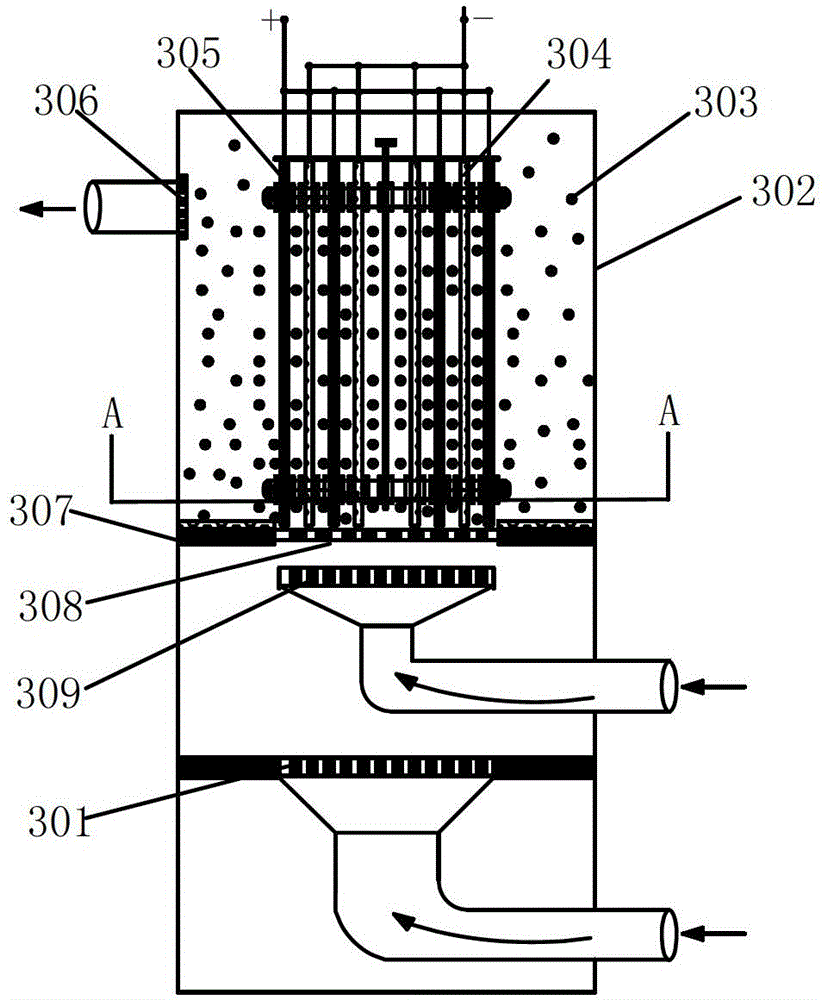

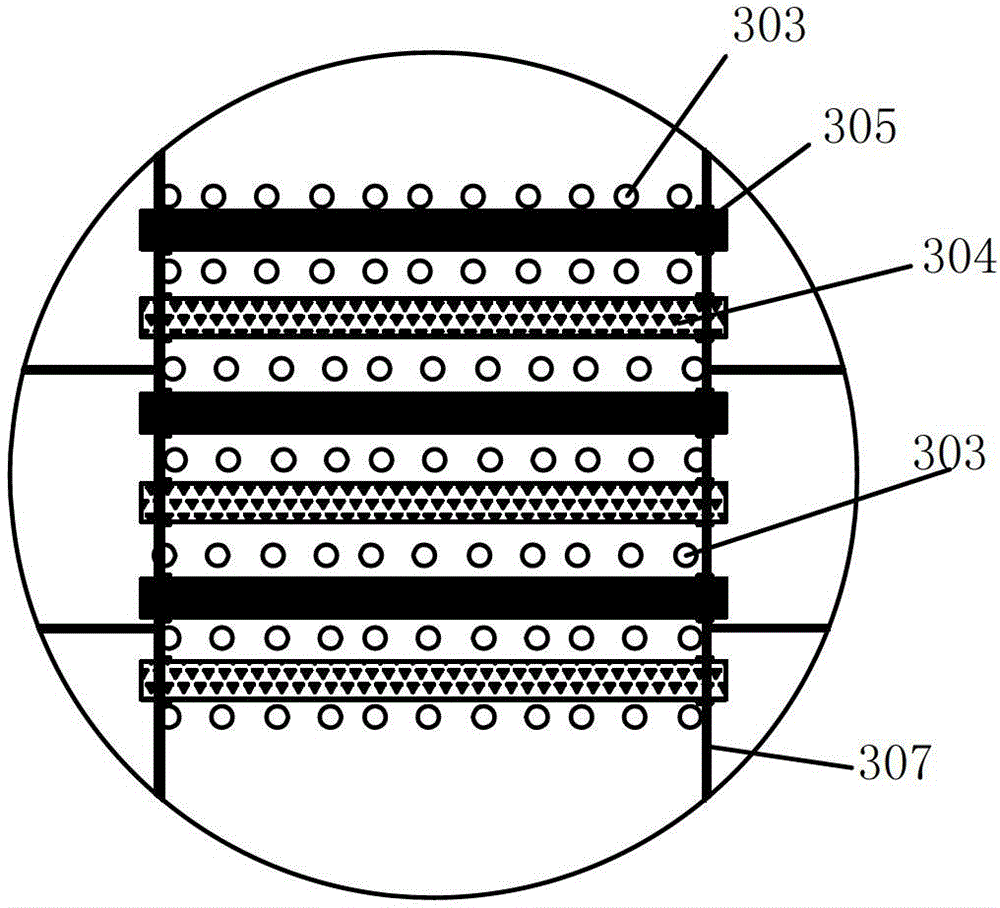

[0035] Such as figure 1 As shown, the bactericidal coking wastewater advanced treatment equipment of the present invention includes a mixed sedimentation tank 1, a multimedia filter 2, a fluidized bed three-dimensional electrode reactor 3, an MBR membrane bioreactor 4, a security filter 5, and an ultraviolet sterilizing device 6 and reverse osmosis device 13, the coking wastewater outlet of the mixed sedimentation tank 1 is connected to the inlet of the multimedia filter 2, and the outlet of the multimedia filter 2 is connected to the wastewater input end of the fluidized bed three-dimensional electrode reactor 3, and the fluidized bed The air input end of the three-dimensional electrode reactor 3 is connected to the blower 7, the waste water output end of the fluidized bed three-dimensional electrode reactor 3 is connected to the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com