Technical method and equipment for recycling iron-contained solid waste

A process method and solid waste technology, which is applied in the field of metallurgy, can solve the problems of insufficient treatment of iron-containing ash sludge and affect the quality of sintered ore products, and achieve the effects of uniform distribution and composition, purification of the environment, and increase of air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

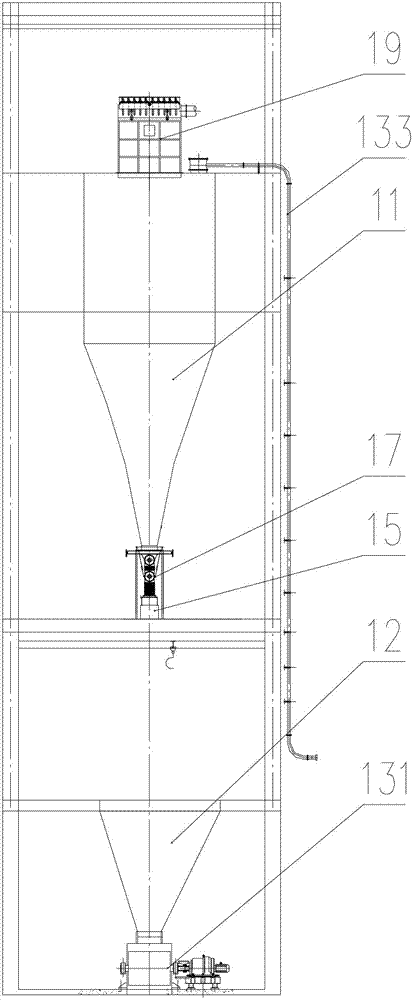

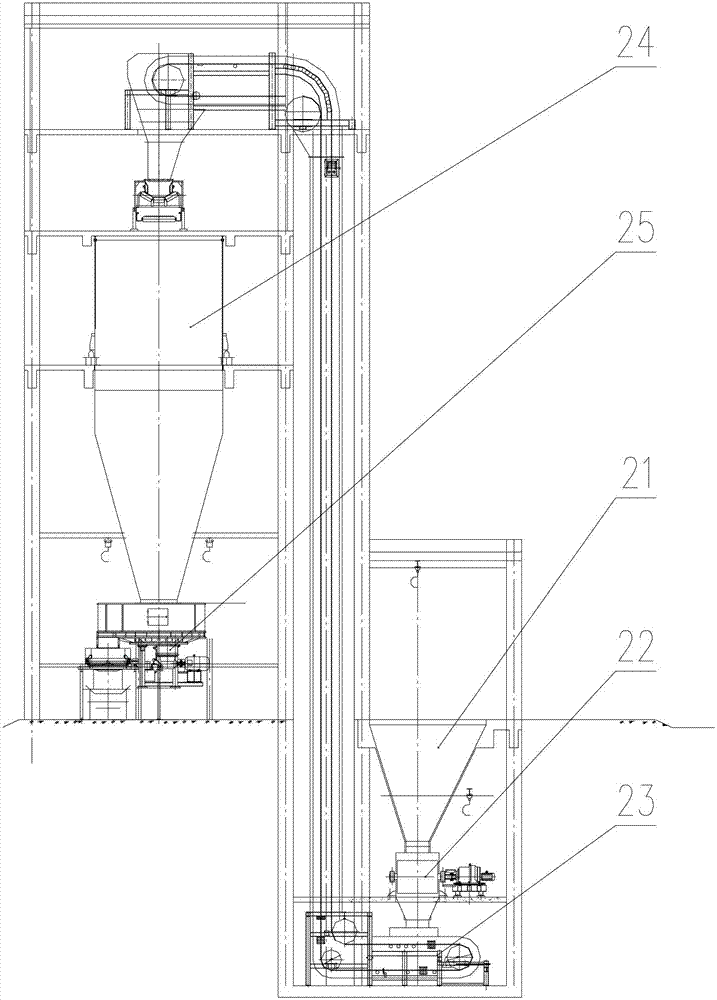

[0032] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

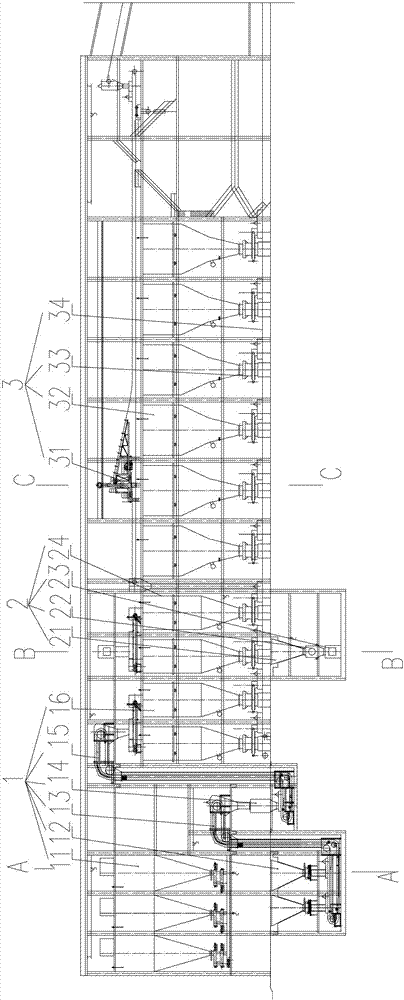

[0033] Such as figure 1 As shown, the present invention proposes a process for recycling iron-containing solid waste, and the process for recycling iron-containing solid waste includes the following steps:

[0034] A: Separate the iron-containing solid waste into categories (or types) according to the original composition and transport them to the corresponding silo for storage. Collect silo 11 and bulk slag collection silo 12, or further subdivide dust removal ash and bulk slag according to composition or grade;

[0035] B: Then determine the category and ratio of the iron-containing solid waste as ingredients according to the iron-containing grade target value. The raw material for sintering is generally iron ore powder. Accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com