Built-in steel-type reinforcing no-beam floor system structure

A beamless floor, built-in technology, applied in the direction of floor slabs, building components, building structures, etc., can solve the problems of affecting the appearance, difficult to handle column supports, and affecting the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

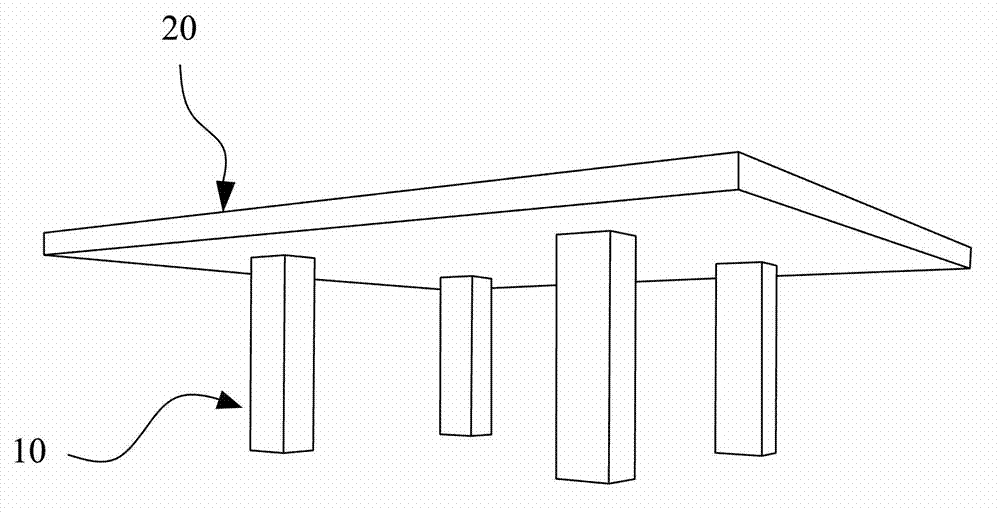

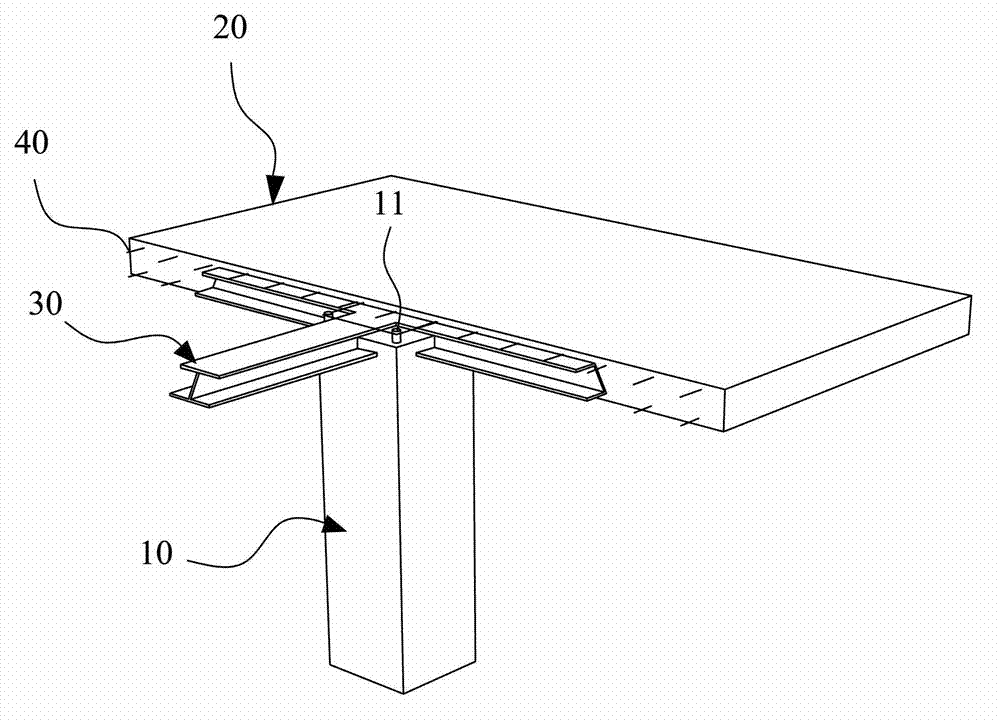

[0032] Please refer to Figure 1 to Figure 4 As shown, it shows the specific structure of the first embodiment of the present invention, including a concrete column 10, a beamless floor 20, and embedded steel 30 and reinforcement 40 accommodated in the beamless floor 20. The concrete The column 10 and the beamless floor 20 are poured integrally.

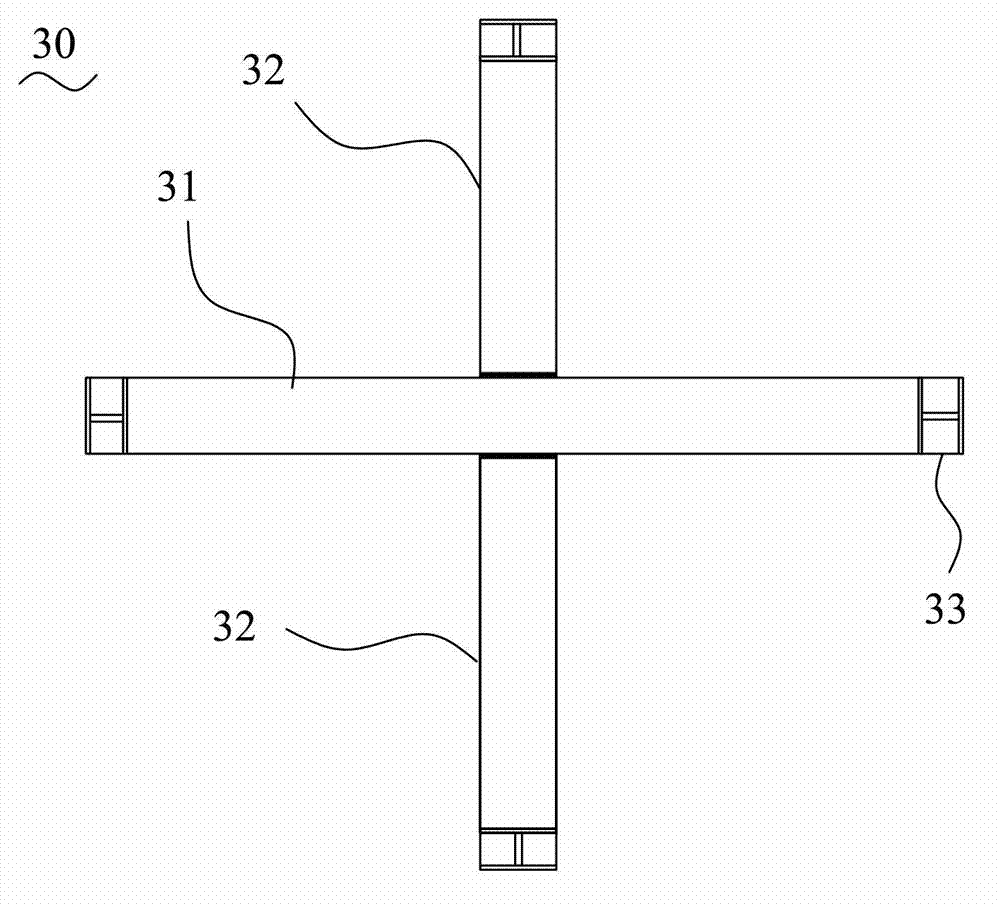

[0033] Among them, such as figure 2 As shown, the embedded section steel 30 is located at the connection node where the concrete column 10 intersects with the beamless floor 20 . The embedded section steel 30 is stored in the plane of the beamless floor 20, such as image 3 As shown, it includes a first beam 31 and a second beam 32, wherein the first beam 31 and the second beam 32 are vertically welded, and the connection strength is ensured through the welding calculation of the equal strength design, so that the beam of the floor can be formed Cruciform structure.

[0034] Such as Figure 4 As shown, the first crossbeam 31 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com