Oil injection control system for engine

A control system and engine technology, applied in the direction of engine control, combustion engine, fuel injection control, etc., can solve problems such as difficulty in engine starting, failure, and difficulty in starting a new car for the first time, so as to avoid the problem of starting failure, improve the impact, and solve the problem. Difficult to start effect for the first time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

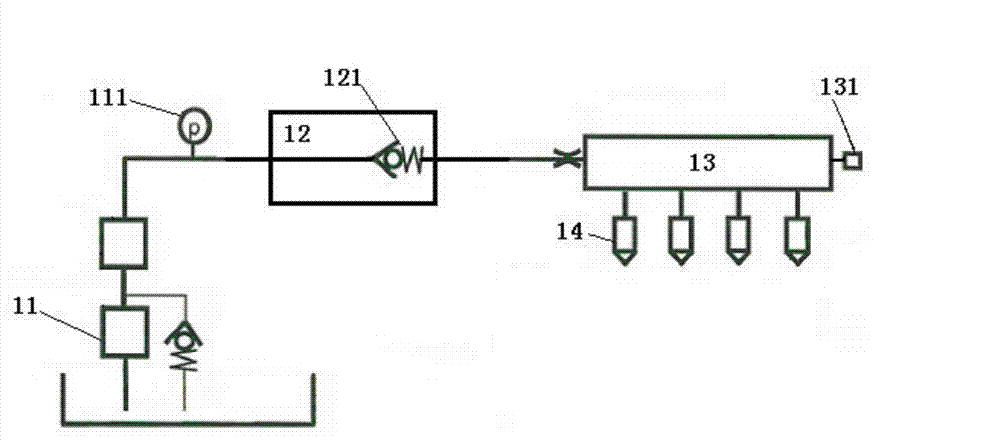

[0043] Engine fuel injection control system, including a fuel injection control module;

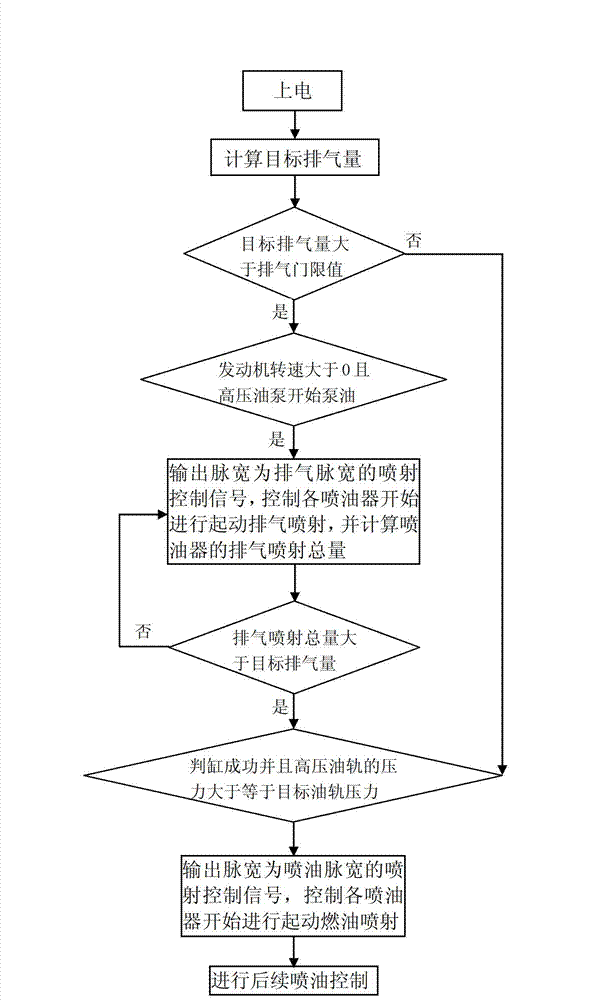

[0044] The workflow of the fuel injection control module, such as image 3 As shown, including the following steps:

[0045] One power up;

[0046] 2. Calculate the target exhaust volume;

[0047] 3. If the target exhaust volume is greater than an exhaust threshold, proceed to step 4, otherwise proceed to step 5;

[0048] four. If the engine speed is greater than 0 and the high-pressure oil pump starts pumping oil, it outputs an injection control signal whose pulse width is the exhaust pulse width, controls each injector to start exhaust gas injection, and calculates the total amount of exhaust gas injection of the injector;

[0049] 5. If the total exhaust gas injection volume of the injector is greater than the target exhaust volume, proceed to step 6; otherwise, proceed to step 4;

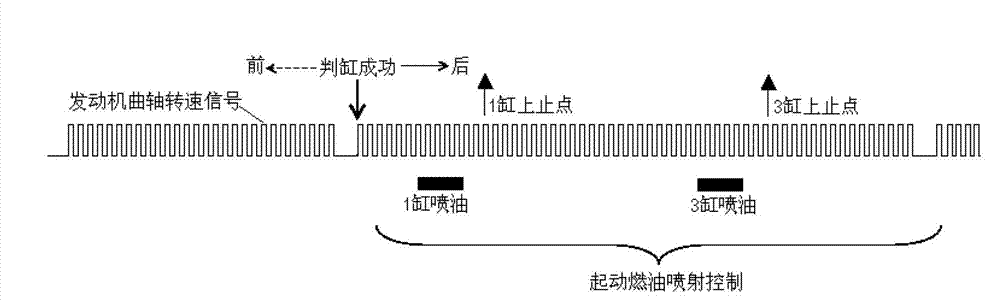

[0050] 6. If the cylinder is judged successfully and the pressure of the high-pressure fuel rail is greater than or...

Embodiment 2

[0054] Based on the first embodiment, the engine fuel injection control system further includes a memory;

[0055] The memory stores the calibrated exhaust threshold value, exhaust pulse width, fuel injection pulse width, and target fuel rail pressure;

[0056] Exhaust threshold and target fuel rail pressure can be calibrated based on experimental and empirical values;

[0057] The exhaust pulse width is calibrated according to the determined minimum fuel injection pulse width Timn;

[0058] The fuel injection pulse width is calibrated according to experimental and empirical values, and the fuel injection pulse width is greater than the determined minimum fuel injection pulse width Timn;

[0059] The minimum fuel injection pulse width refers to the minimum pulse width for the injector to achieve effective fuel injection. The size of the minimum fuel injection pulse width Timn mainly depends on the electromagnetic force of the solenoid valve to lift the injector needle valve, the fuel ra...

Embodiment 3

[0067] Based on the second embodiment, the memory also stores a calibrated exhaust interval, and the calibrated exhaust interval is greater than or equal to the minimum fuel injection pulse width Timn;

[0068] The fuel injection control module outputs an exhaust injection control signal with a pulse width of the exhaust pulse width, and when controlling each injector to start exhaust injection, the time interval between two consecutive injections of the same injector is equal to the calibrated Exhaust interval.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com