Pneumatic actuator for angular travel valve

A pneumatic actuator, angular stroke technology, applied in engine components, valve operation/release devices, valve details, etc., can solve the problems of many fault points, uneven rotation, high manufacturing cost, and achieve low production cost and structure. Simple, long-lasting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

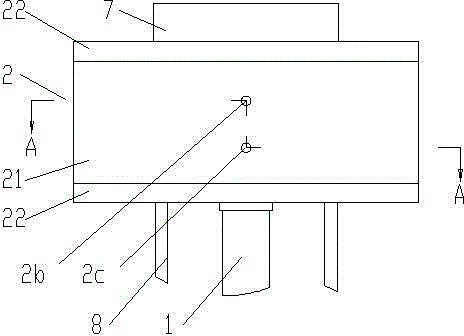

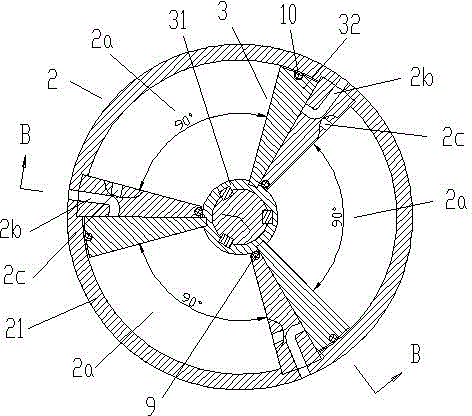

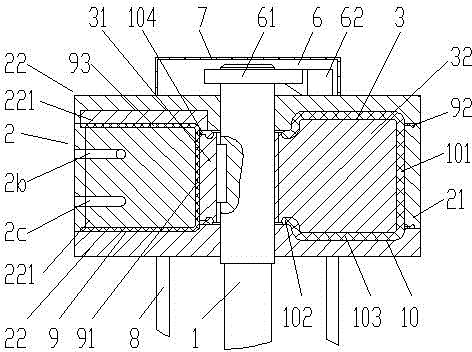

[0022] Example 1 see figure 1 , figure 2 , image 3 , a pneumatic actuator for quarter-turn valves, comprising a quarter-turn valve stem 1, a cylinder block 2, a piston 3, and a reset device for resetting the piston 3, and the cylinder block 2 is formed with mutually independent 3 chambers 2a distributed in a circle, and each chamber 2a communicates with an air intake channel 2b and an exhaust channel 2c for intake and exhaust respectively; the piston 3 consists of a piston sleeve 31 and 3 piston plates 32, the piston sleeve 31 is set on the piston sleeve 31 fixed on the valve stem 1 through a key connection, and the circumference of the piston pieces 32 is evenly distributed on the outside of the piston sleeve 31, and each piston piece 32 is respectively located in a corresponding chamber 2a, and the piston The piece 32 can be driven by compressed air to rotate 0-90° in the chamber 2a; the resetting device is used to make the piston 3 rotate and reset.

[0023] The cyl...

Embodiment 2

[0035] Example 2 see Figure 9 , Figure 10 The valve rod 1 is located outside the cylinder body 2 and is connected with an elastic element 4 for making the piston 3 rotate and reset.

[0036] The elastic element 4 is a coil spring, the inner end of the coil spring is fixed on the valve rod 1, the outer end of the coil spring is fixed on the transparent cover 22 of the cylinder block 2 through the pin shaft 23, and the coil spring is provided with a coil spring Cover 5 is protected.

[0037] The rest of the structure of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com