Dynamic wave-front testing device

A test device and wavefront technology, applied in the field of optical testing, can solve problems such as the inability to realize the optical wavefront test of external light source and white light wavefront test, the inability to truly reflect the working wavefront of the lens, and the inability to evaluate the optical system to achieve high precision High, less artificial links, high stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

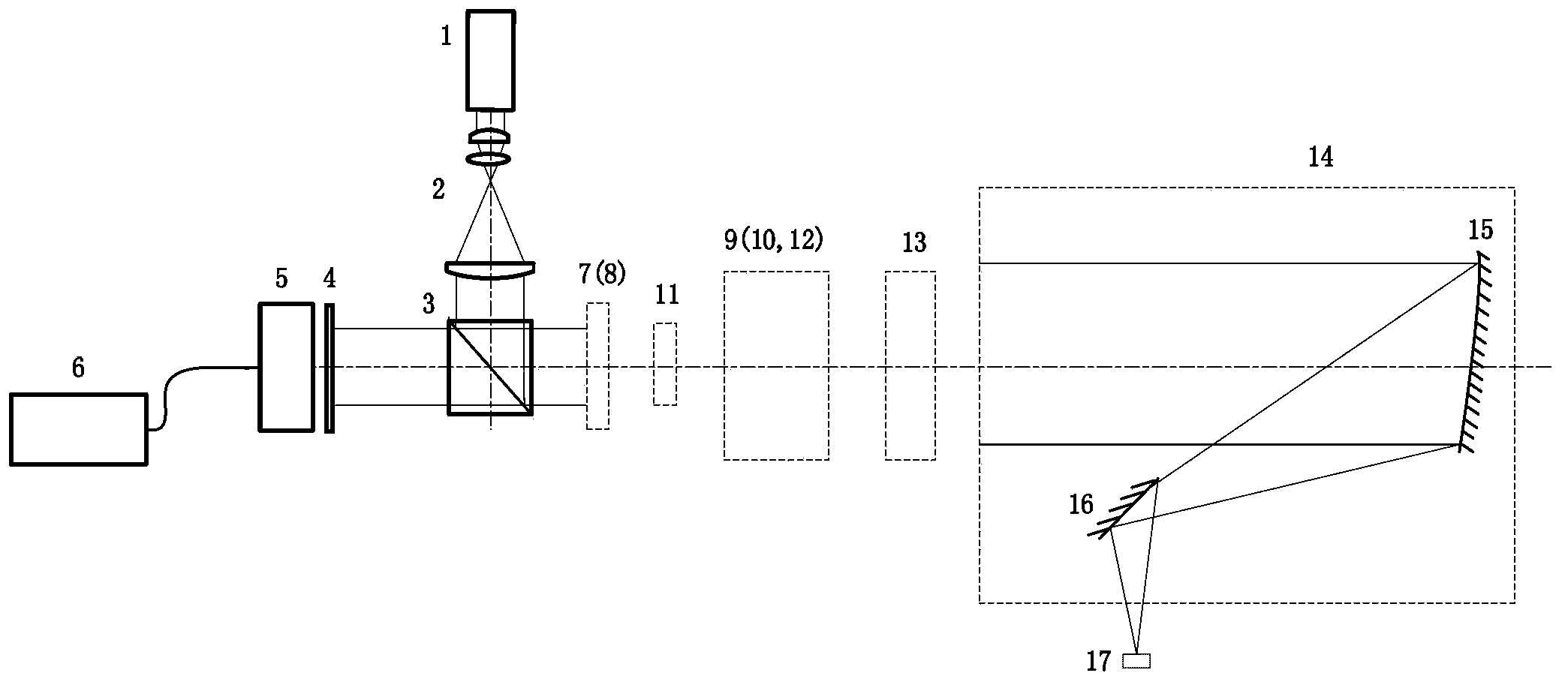

[0018] The invention provides a dynamic wavefront testing device, which comprises an active light source, a passive light source, a beam splitter, a calibration mirror, a standard lens, a microlens array, a CCD detector and a computer; the beam splitter is arranged on the active light source And the incident light path of the passive light source; the beam splitter divides the incident light of the active light source into active reflected light and active transmitted light; the beam splitter divides the incident light of the passive light source into passive transmitted light and passive reflected light; The optical path of the active reflected light or set on the outgoing light path of the passive light source; the calibration mirror and the standard lens are set on the light path between the beam splitter and the optical element to be tested; the microlens array is set on the light path of the passive transmitted light or set on the The active reflected light is transmitted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com