Miniature onboard cloud droplet sampling system and working method thereof

A sampling system and minicomputer technology, applied in sampling devices and other directions, can solve the problems of high purchase cost, large volume of aeronautical atmospheric observation samplers, hindering research development, etc., and achieve convenient processing, improved feasibility and practicability, and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

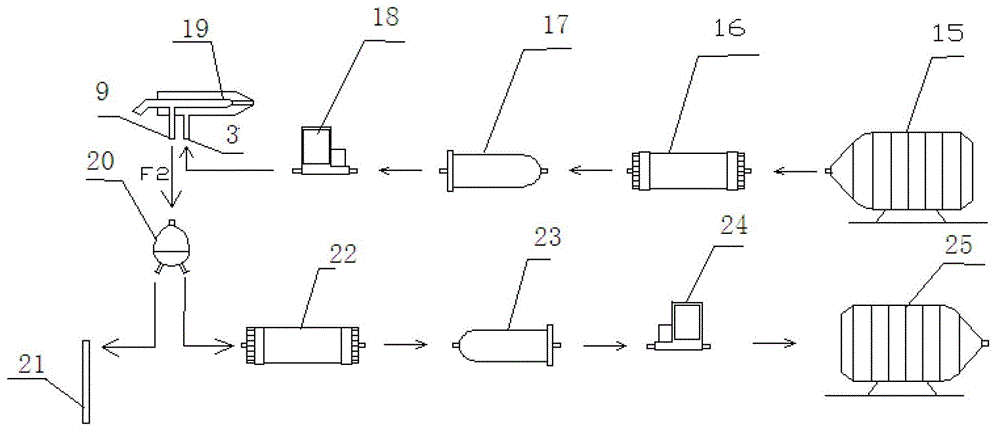

[0034] Such as Figure 1-3 shown.

[0035] A small airborne cloud droplet sampling system, comprising a gas compression pump 15, a dryer 16, a filter 17, a mass flow controller 18, a small airborne cloud droplet sampling device 19, and a flow diversion device 20 sequentially connected in accordance with the direction of the sampling airflow , sampling membrane 21, drier 22, filter 23, mass flow controller 24 and air pump 25;

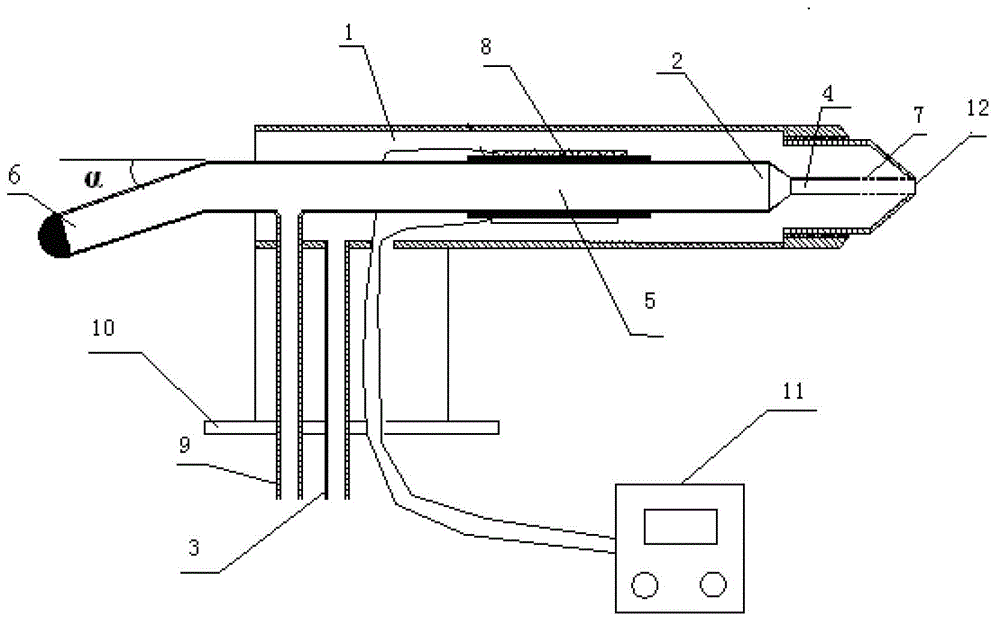

[0036] Described small-sized airborne cloud drop sampling device comprises air inlet chamber 1 and collection chamber 2, and described collection chamber 2 is arranged on the inside of air inlet chamber 1; The front end of described air inlet chamber 1 and the outer edge of the sampling end of collection chamber connected, the front end of the air inlet chamber 1 is tapered, and the tail of the air inlet chamber 1 is provided with an air inlet pipe 3; the collection chamber 2 includes a tubular sampling end 4, a preheating chamber 5 and a pipe shaped c...

Embodiment 2

[0040] A kind of method that utilizes the collection cloud droplet of system as described in embodiment 1, comprises steps as follows:

[0041] (1) After the plane takes off, first turn on the heating device and preheat the preheating chamber to 48-52°C;

[0042] (2) After flying to the target collection airspace, turn on the gas compression pump and air extraction pump at the same time;

[0043] (3) The sampled gas enters the intake cavity along the intake pipe;

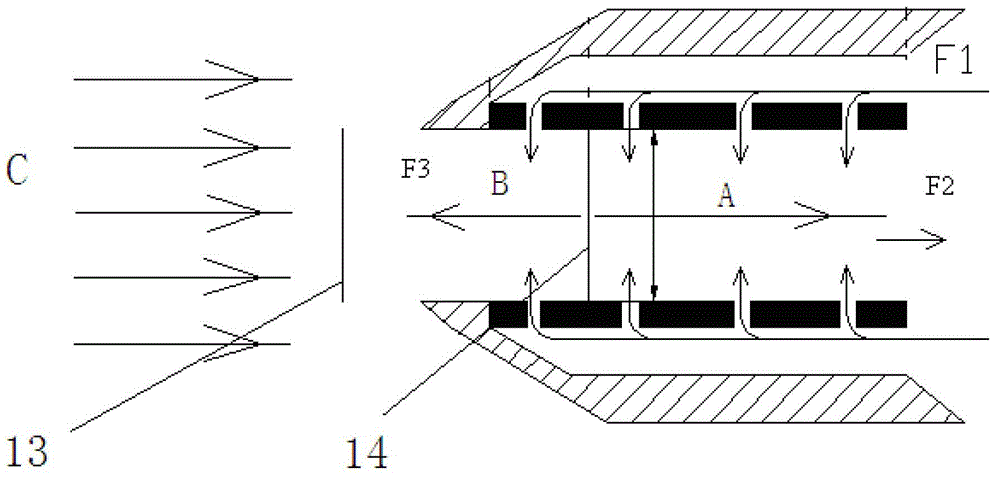

[0044] (4) The sampling gas in the intake chamber enters the collection chamber along the micropores on the tubular sampling end, the flow rate F1 of the intake pipe is greater than the flow rate F2 of the exhaust pipe, and the sampling gas entering from the intake pipe passes through the tube with micropores It is divided into two channels of sampling gas when the sampling end is shaped: one of the sampling gas A has the same flow rate F2 and the same direction as the sampling gas of the extraction pipe, and the o...

Embodiment 3

[0052] Cloud droplet sampling system as described in embodiment 1, its difference is,

[0053] The length of the tubular sampling end 4: 8mm, the diameter of the tubular sampling end: 1.5mm; there are multiple circles of microholes around the tubular sampling end, the number of micropores in each circle is 6, and the interval between adjacent circles is 1.5 mm. mm; the diameter of the micropore: 10 μm; the diameter of the preheating cavity: 4 mm; the diameter range of the air inlet cavity: 18 mm. The tubular capturing end is at an angle of 25° counterclockwise to the horizontal.

[0054] The particle size range of the aerosol particles or cloud droplets collected by the cloud droplet sampling device described in this embodiment is between 5-10 μm, which meets the experimental requirements for selectively collecting large aerosol particles or cloud droplets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com