Wide-range magnetic field viscometer for high-temperature melt, and method for measuring viscosity by using same

A high-temperature melt and wide-range technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of limited measurement range and fluid types, and achieve the effect of short measurement period and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

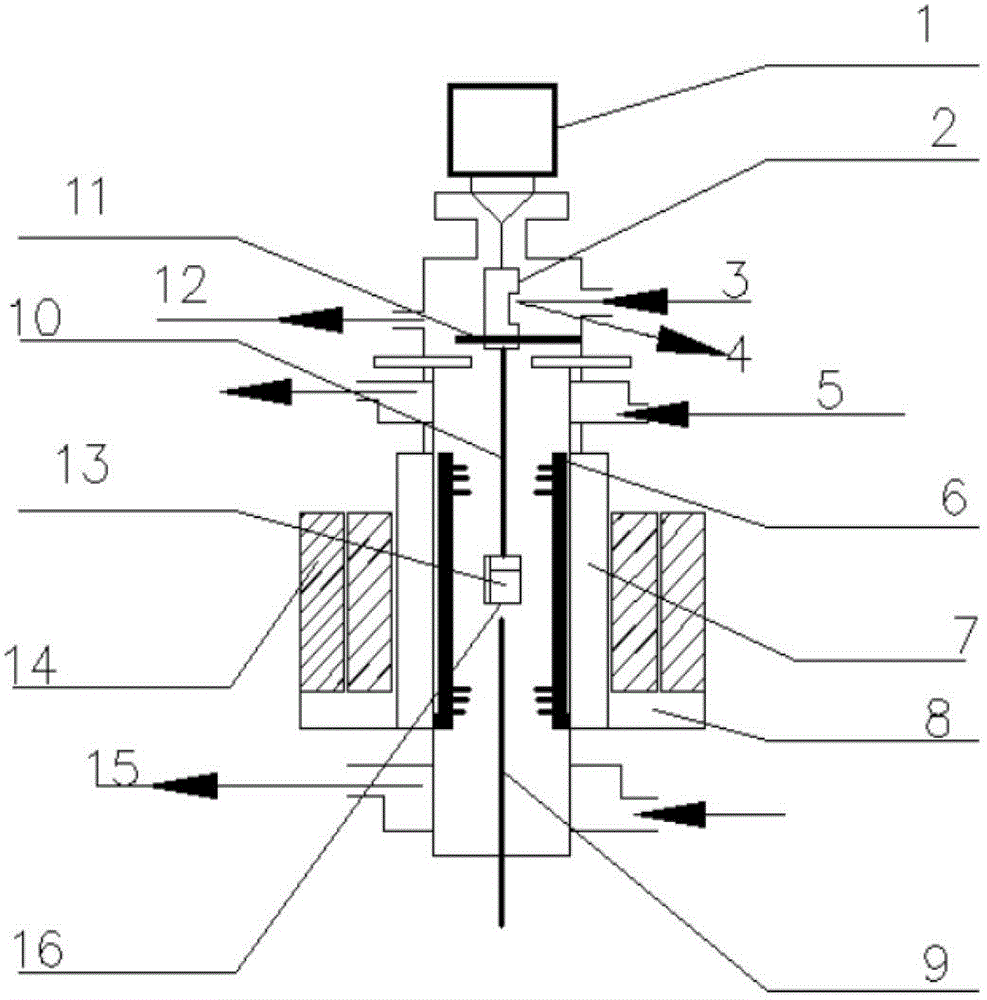

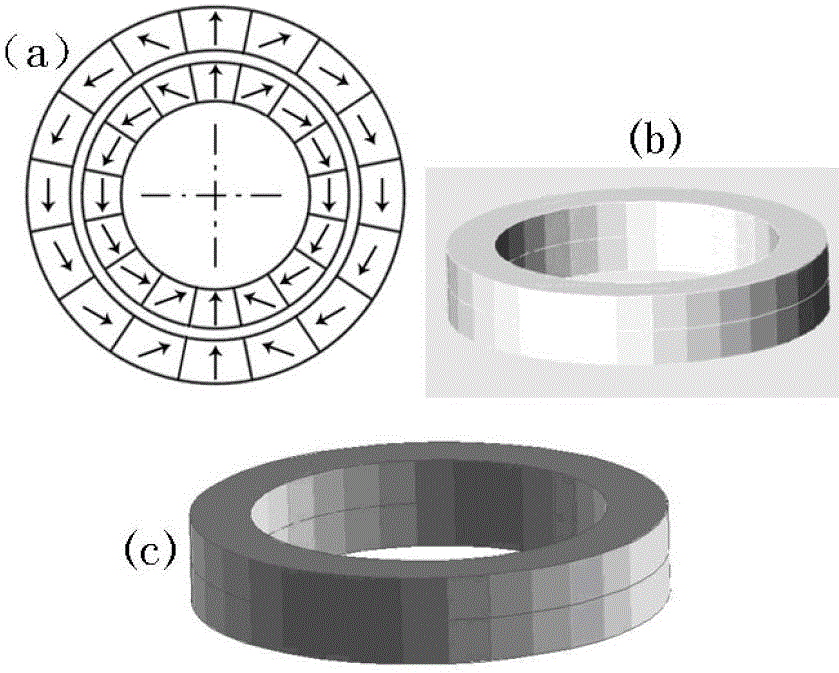

Method used

Image

Examples

Embodiment 1

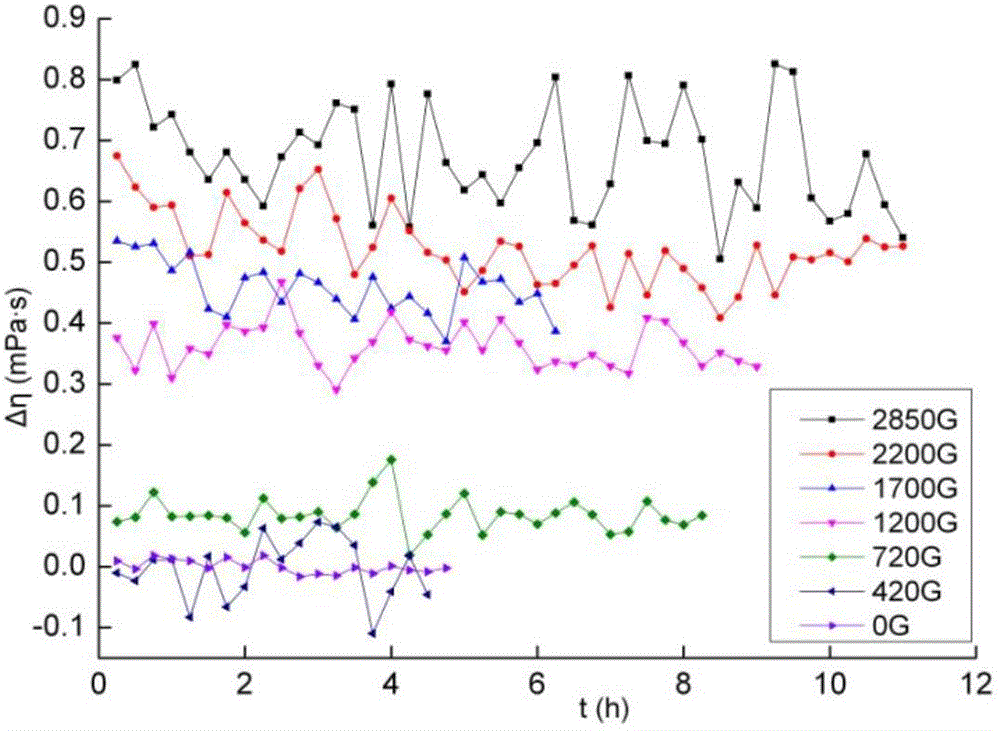

[0044] Measure the viscosity of tap water under different magnetic fields:

[0045] (1) Place the sample water in the sample holding device and lower it to the position of the heating body;

[0046] (2) Evacuate the measuring cylinder, fill it with argon, and heat it to 30-50℃ for 30min;

[0047] (3) Rotate the worm to select the magnetic induction intensity of the magnetic field.

[0048] (4) Turn on the stepping motor, the rotating shaft drives the sample holding device to rotate, the He-Ne laser outside the instrument emits laser light and irradiates the optical element on the rotating shaft, and the laser light is reflected back to the detector through the optical element, according to the incident light and reflected light The time interval of the rotation decay rate is measured, and then the corresponding viscosity value is obtained according to the calculation formula (I) of the rotation decay rate and viscosity,

[0049] v = ...

Embodiment 2

[0054] Viscosity values of Al-0.5%Fe alloy melt under different magnetic field environments:

[0055] (1) Place the Al-0.5%Fe alloy sample in the sample holding device and lower it to the position of the heating body;

[0056] (2) Evacuate the measuring cylinder, fill it with argon protective gas, heat it to 875 °C for 30 minutes and then measure it, and then cool down every 20 °C, and each measurement temperature point needs to be kept warm for 30 minutes;

[0057] (3) Rotate the worm to select the magnetic induction intensity of the magnetic field; respectively select the magnetic induction intensity as: 0G, 420G, 650G, 880G

[0058] (4) Turn on the stepping motor, the rotating shaft drives the sample holding device to rotate, the HeNe laser outside the instrument emits laser light and irradiates the optical element on the rotating shaft, and the laser light is reflected back to the detector through the optical element, according to the time of incident light and reflected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com