Seal checking method and seal checking device

A technology of a calibration device and a calibration method, which is applied in the directions of instruments, inductive record carriers, character and pattern recognition, etc., to achieve the effects of high speed, reduced workload, and reduced probability of calibration errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

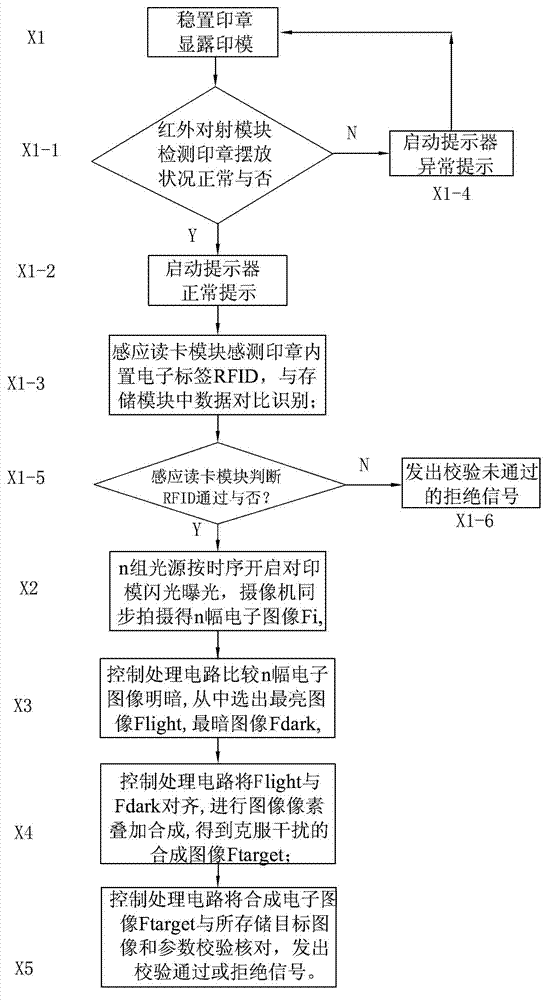

Method used

Image

Examples

Embodiment 1

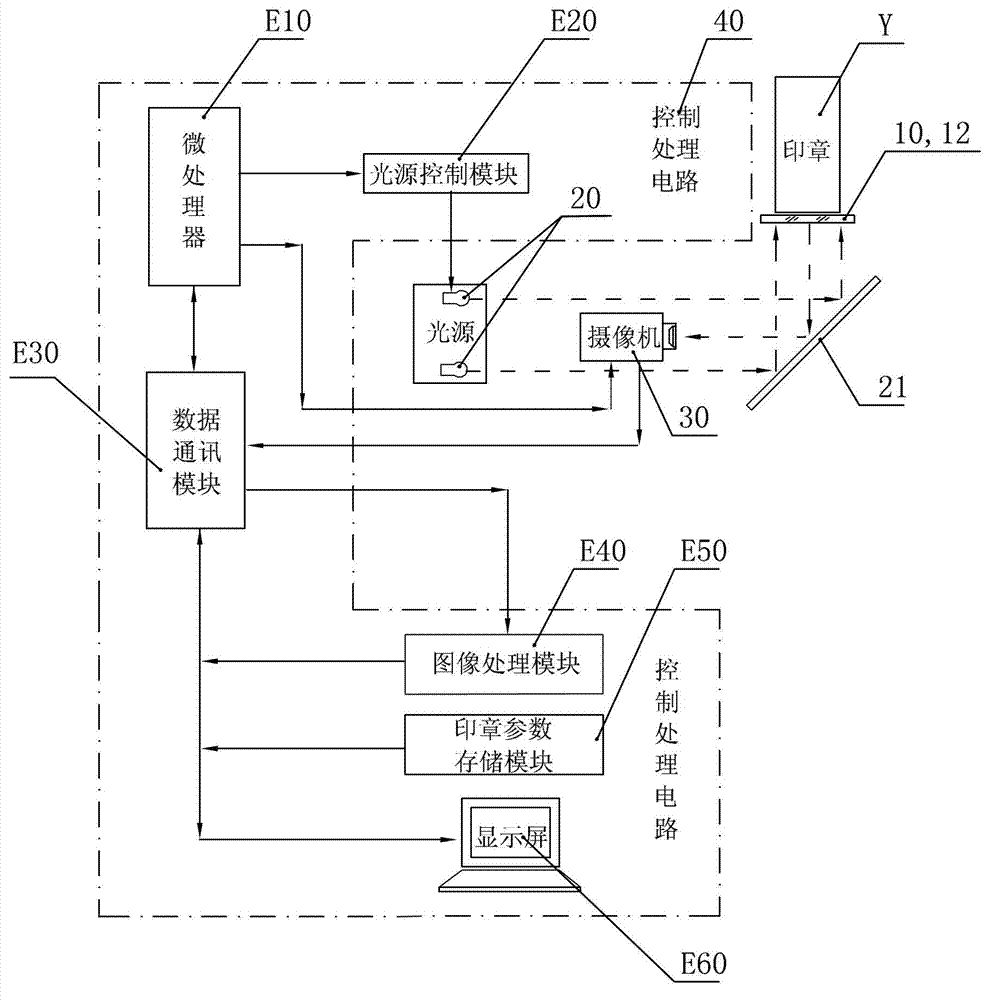

[0067] Such as figure 2 , which is a schematic circuit block diagram of Embodiment 1 of the seal verification device of the present invention. It includes a transparent window 10 for framing the impression of the stamp Y to be inspected. The device is provided with n groups of light sources 20 that project light to the impression of the stamp Y in a circular distribution, and a camera for taking pictures of the impression. Camera 30, controlling n groups of light sources 20 and the control processing circuit 40 for cooperating with cameras 30 and processing impression images; between the transparent window and the optical path of the light source 20 and camera 30, an oblique plane mirror 21 for turning light is provided; The control processing circuit 40 includes: a microprocessor E10, a light source control module E20, a data communication module E30, an image processing module E40, a storage module E50 for storing stamp parameters, a display screen E60; the controlled end o...

Embodiment 2

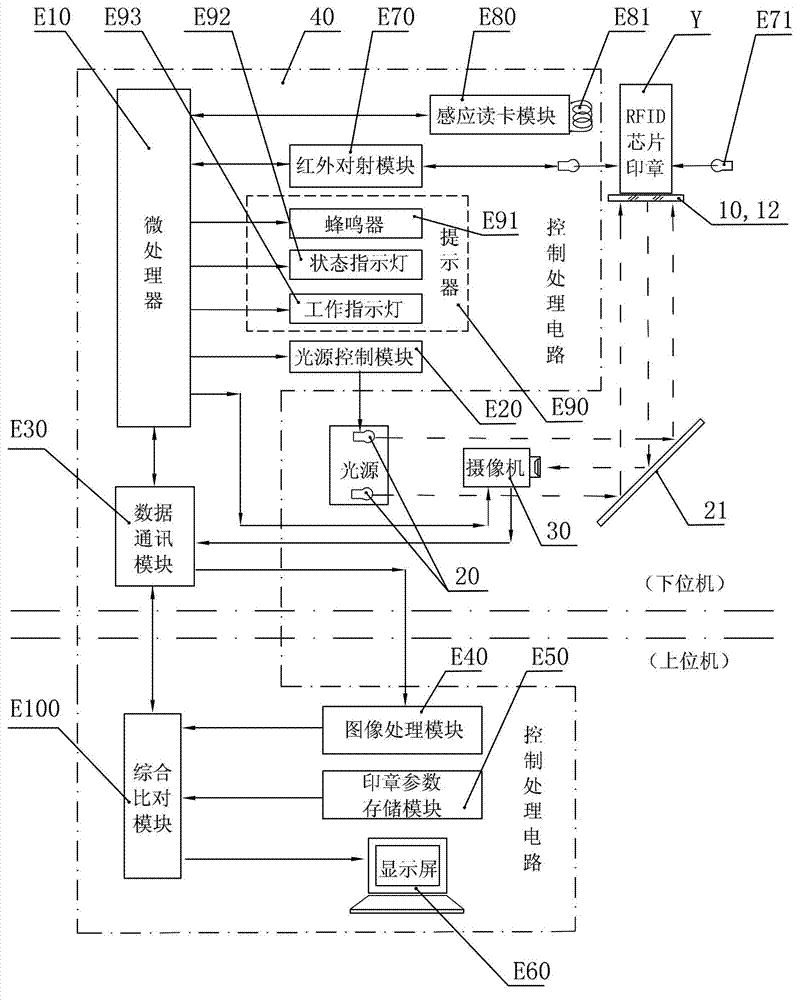

[0070] Such as image 3 , which is a schematic block diagram of the circuit structure of Embodiment 2 of the seal verification device of the present invention. On the basis of Embodiment 1, it has the following further circuit structure improvements:

[0071]The seal Y is provided with an RFID electronic tag Y10; the control processing circuit 40 also includes an infrared through-shooting module E70 connected to an infrared through-shooting lamp E71, an induction card reading module E80 connected to an induction coil E81, a prompter E90, and a comprehensive comparison Module E100; the I / O port of the infrared radiation module E70, the I / O port of the inductive card reader module E80, and the input end of the prompter E90 are respectively connected to the corresponding interface of the microprocessor E10; the image processing module E40 The output end of the storage module E50 and the input end of the display screen E60 are respectively connected to the corresponding ports of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com