Concentrating photovoltaic cell chip

A concentrating photovoltaic and cell technology, applied in the field of solar power generation, can solve the problems of small rated current, easy-to-fuse negative electrode, and reduce the conversion efficiency of concentrating photovoltaic cells, so as to achieve the effect of improving conversion efficiency and increasing the light-receiving area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

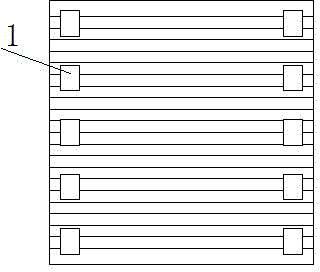

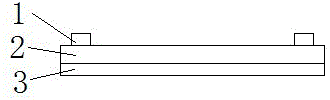

[0015] A concentrated photovoltaic cell, such as Figure 1~2 As shown, one side of the substrate layer 2 of the concentrated photovoltaic cell is the positive electrode layer 3 , and the other side is the negative electrode segment layer 1 .

[0016] The substrate layer 2 of the concentrated photovoltaic cell combines the positive electrode layer 3 and multiple negative electrode segment layers 1 skillfully through a special process, which can ensure that large currents are smoothly guided through the positive electrode layer 3 and the negative electrode segment layer 1 At the same time, it can also ensure that each electrode layer and connecting wire can withstand the rated current of 10~50 amperes.

[0017] The negative electrode segment layer 1 is processed on the substrate layer 2 of the concentrated photovoltaic cell. The negative electrode segment layer 1 ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com