Intelligent longitudinally-interconnected feeder automation system

A feeder automation and vertical technology, applied in the direction of emergency protection circuit devices, electrical components, etc., can solve the problems of power failure of the whole line, long fault isolation time, affecting the reliability and quality of power supply, so as to reduce the power failure time and improve the reliability of power supply sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

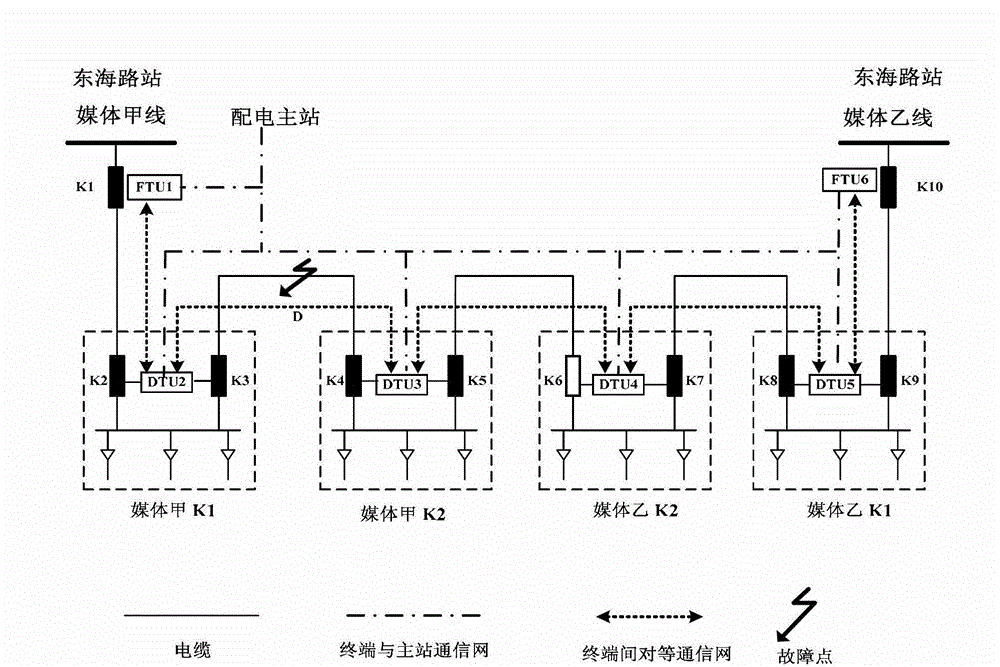

[0032] Below in conjunction with accompanying drawing this patent is described further.

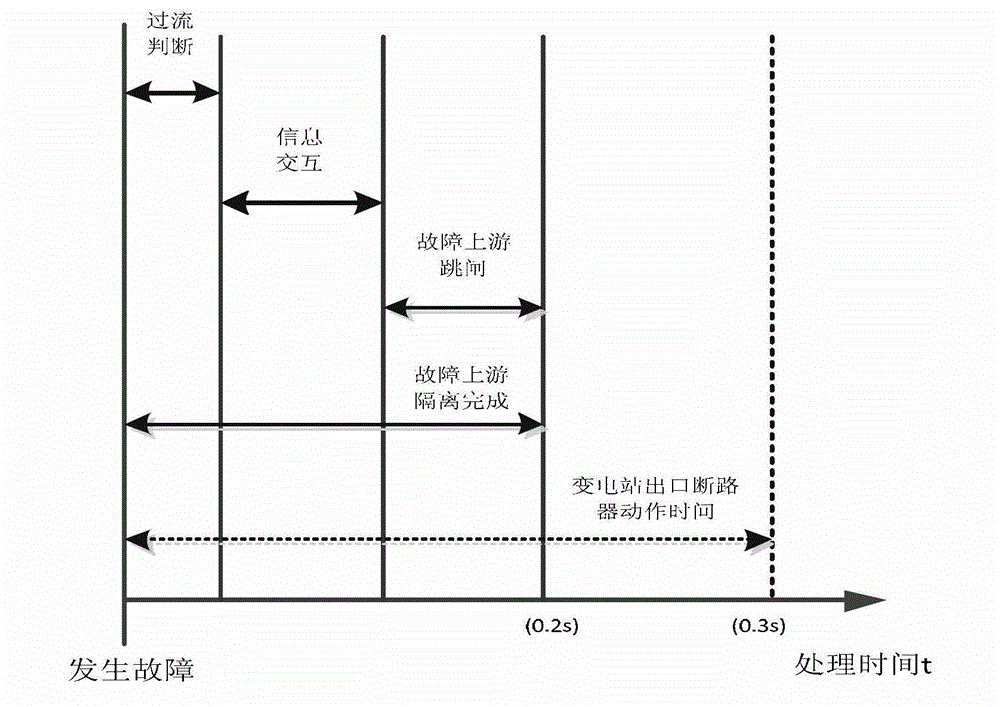

[0033] An intelligent vertically interconnected feeder automation system, including intelligent power distribution terminals, and information interaction between adjacent intelligent power distribution terminals located in the same power supply topology network through vertical communication protocols Carry out comprehensive processing and logical judgment on the signals of itself and adjacent intelligent power distribution terminals, and realize fault location, fault area isolation and non-fault area restoration of power supply action before the substation exit switch action; and the system also provides a consideration of instantaneous An intelligent distributed first aid method for sexual failures.

[0034] The inside of the intelligent power distribution terminal is provided with a DFT algorithm module that calculates the signal of each half of the power frequency fundamental wave; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com