Component mounting and dispatching optimization method for chip mounter on basis of quantum neural network

A technology of quantum nerves and optimization methods, which is applied to the biological neural network model and the assembly of printed circuits with electrical components, can solve problems such as increased optimization solution time and complex mathematical models for placement scheduling, so as to shorten the placement time and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The quantum neural network-based placement scheduling optimization method for placement machine components of the present invention will be described in detail below with reference to the accompanying drawings.

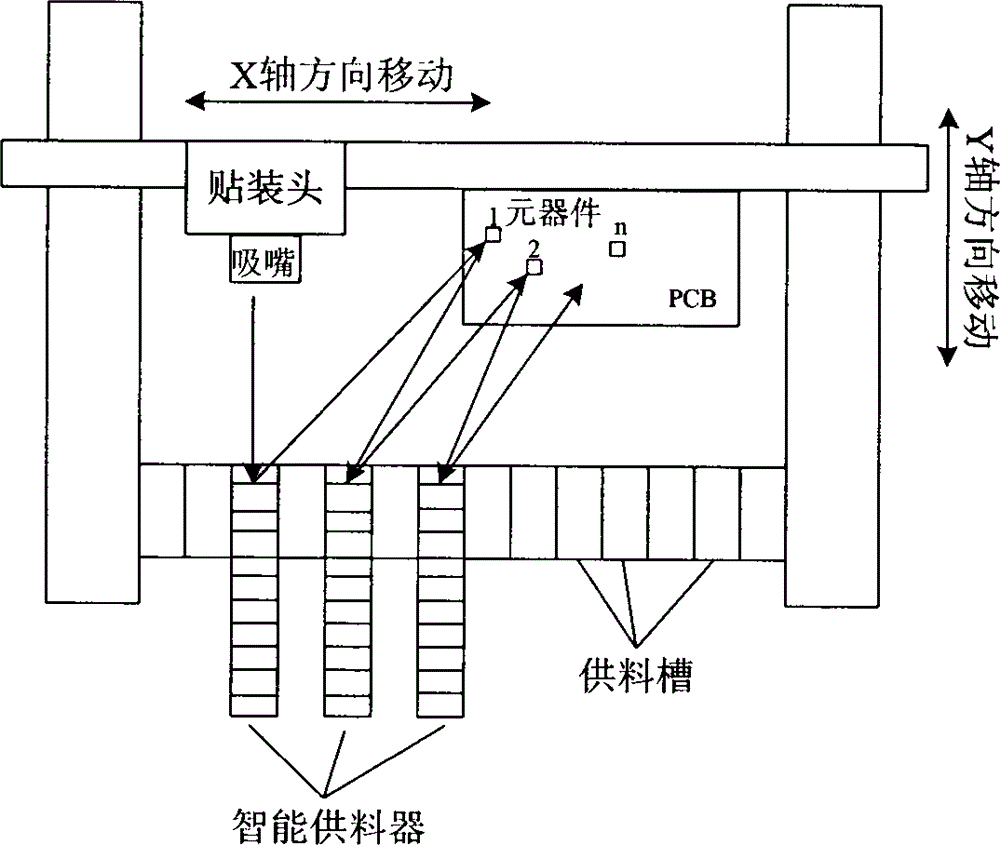

[0014] as attached figure 1 , in the quantum neural network-based component placement scheduling optimization method of the present invention, the working principle of component placement is: first, the placement head moves to the position of the component intelligent feeder, and absorbs the component device; then the placement head moves to the position of the first component to complete the placement of component 1, and then moves to the position of the second device to complete the placement of device 2, and repeats the cycle of placement until the PCB on the All components are mounted.

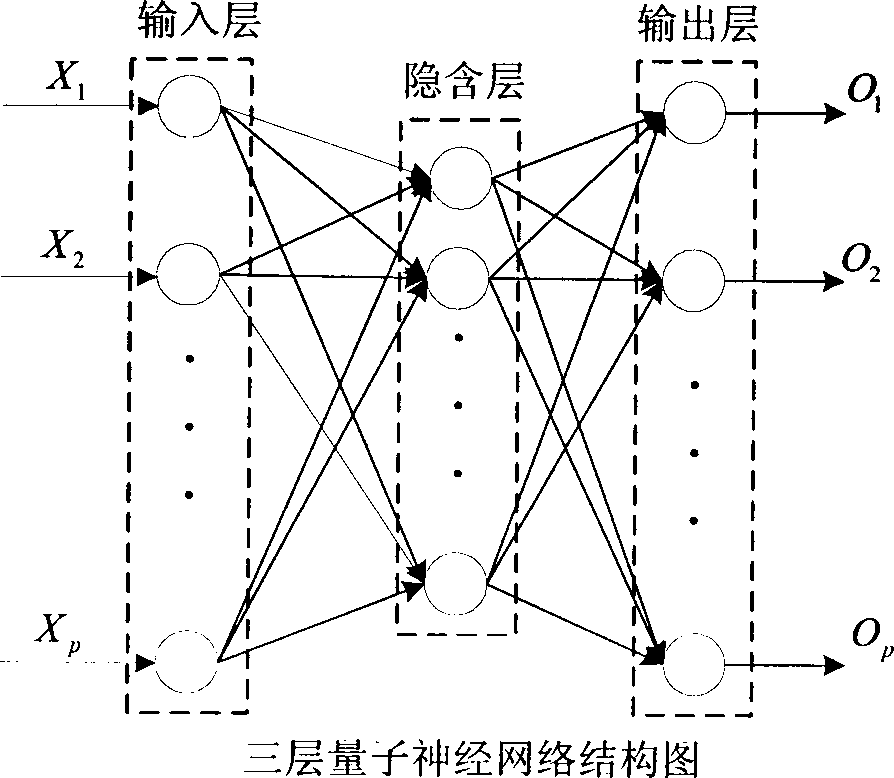

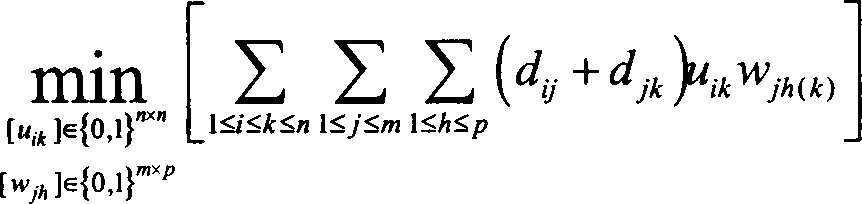

[0015] An optimization method for placement scheduling of placement machine components based on quantum neural network, the specific process is as follows:

[0016] Step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com