Thickening and dewatering filter

A technology of concentration dehydration and filter, which is applied in the direction of filtration separation, fixed filter element filter, chemical instrument and method, etc. It can solve the problems of cumbersome operation steps, high production cost and complex structure, and achieve the reduction of control components and easy operation , The effect of simple and optimized equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

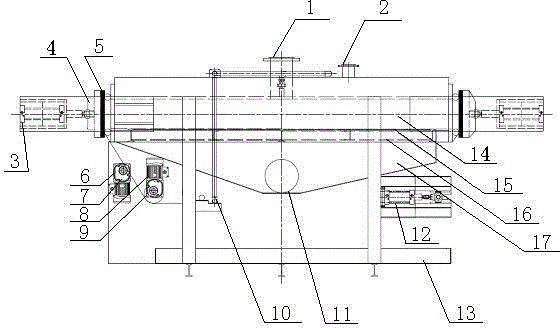

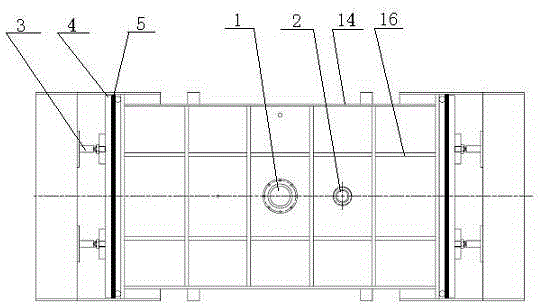

[0012] see figure 1 , figure 2 Shown, the fuselage of filter machine of the present invention is made up of upper cavity 14 and lower cavity 17, is welded with dirty liquid inlet 1 and dirty liquid outlet 2 on upper cavity 14, is welded with clean liquid outlet on lower cavity 17 11. The upper cavity 14 and the lower cavity 17 are welded as a whole, and the middle fixed welding mesh plate 16 divides it into two upper and lower cavities. The filter cloth 15 is arranged on the mesh plate 16 , and side holes are correspondingly arranged on the two side walls of the connection between the mesh plate 16 and the upper cavity 14 , and the side holes are used for passing the filter cloth 15 . Install the sealing bracket 4 outside the upper cavity 14, the sealing bracket 4 is provided with a sealing strip 5, the sealing strip 5 corresponds to the side wall and the position of the side hole of the upper cavity 14, and a compression cylinder is installed on the sealing bracket 4 3. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com