Portable-type laser cleaning head

A laser cleaning and portable technology, applied in the direction of cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of coupling loss, low power, low single pulse energy, etc., and achieve the advantages of easy operation, increased power, and increased laser output power Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

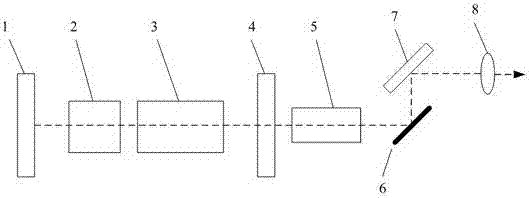

[0018] figure 1 It is a structural schematic diagram of Embodiment 1 of the present invention, which includes a total reflection mirror 1, an acousto-optic Q-switching switch 2, a semiconductor pump module 3, an output mirror 4, a beam expander mirror 5 and a 45° total reflection mirror arranged in sequence on the main optical path Mirror 6 is provided with a scanning vibrating mirror 7 on the reflection optical path of the 45 ° total reflection mirror 6, and a focusing lens 8 is provided on the reflection optical path of the scanning vibration mirror 7. The 45 ° total reflection mirror 6 is placed at an angle of 45 ° with the main optical path, The scanning galvanometer 7 is placed at an angle of 45° to the main optical path. The acousto-optic Q-switching switch 2 is a single-head acousto-optic Q-switching switch or a double-head acousto-optic Q-switching switch.

[0019] In this embodiment, the acousto-optic Q-switching switch is preferably a British Gucci double-head Q swi...

Embodiment 2

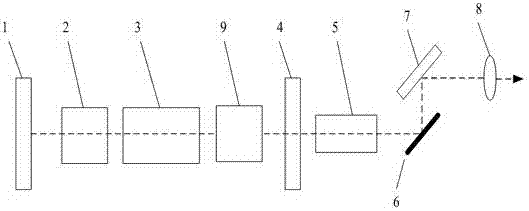

[0021] figure 2 It is a structural schematic diagram of Embodiment 2 of the present invention. The structure and principle of this embodiment are basically the same as Embodiment 1. The difference is that the main optical path between the semiconductor pump module 3 and the output mirror 4 is also provided with a second acousto-optic Q switch 9. In this embodiment, both the acousto-optic Q-switch and the second acousto-optic Q-switch use a British Gucci single-head Q switch. The GTPC-200 semiconductor pump module of Beijing Jitai Jiye is used, and the pump output power is 200 watts. Use an output mirror with a transmittance of 40% and double the beam expander. It adopts a high-speed laser scanning galvanometer for 1064nm wavelength and a 45° total reflection mirror with high reflection for 1064nm wavelength laser. The cavity length of the acousto-optic Q-switched solid-state laser composed of the total reflection mirror 1, the acousto-optic Q-switched switch 2, the semicon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com