Rectangular laser generating device for high-power dual-wavelength semi-conductor

A laser generation and dual-wavelength technology, which is applied in the direction of semiconductor lasers, lasers, phonon exciters, etc., can solve the problems that the output power is difficult to increase, light and heat return transmission, damage, and the output power of semiconductor lasers is difficult to further increase.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

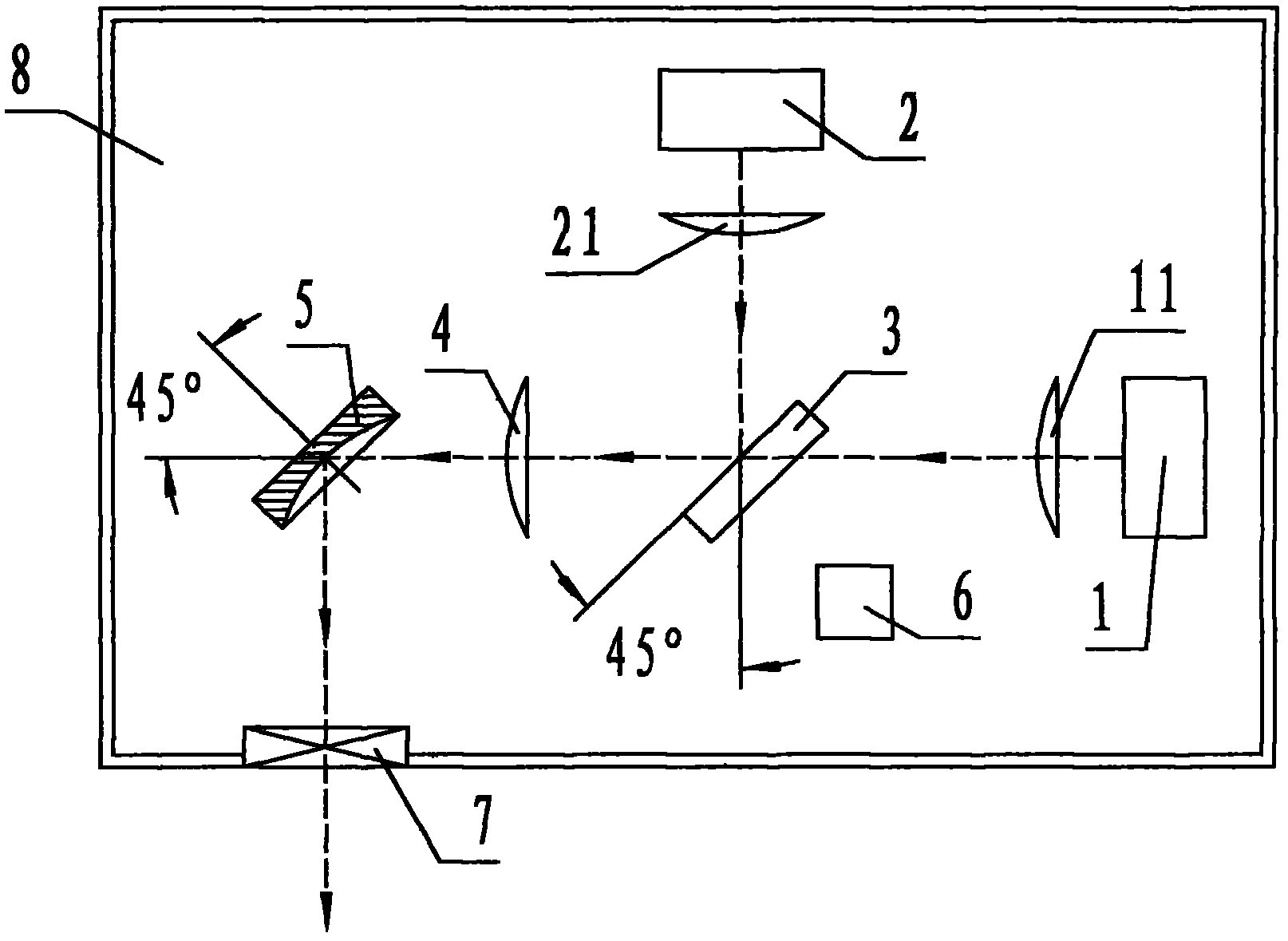

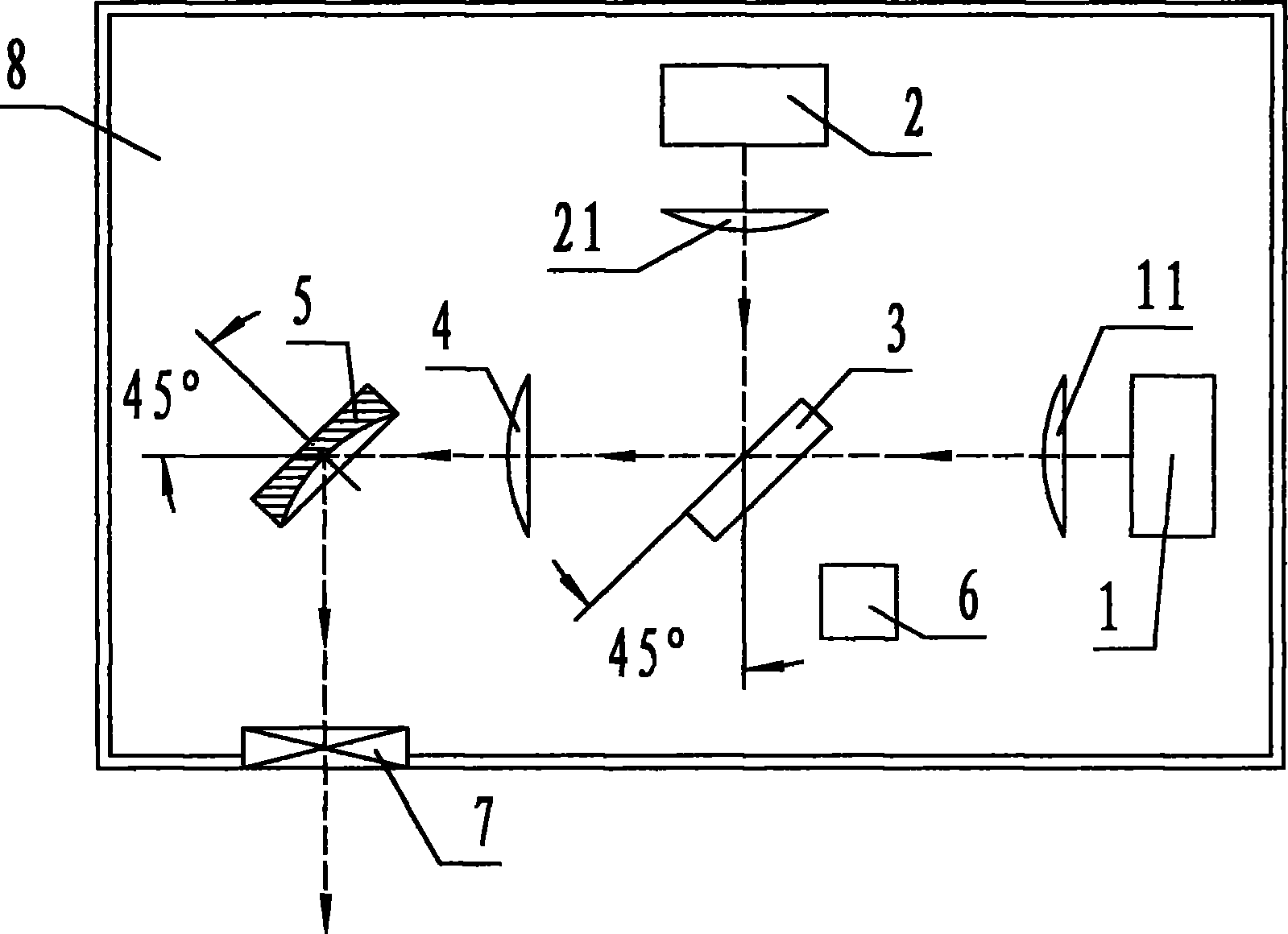

[0026] refer to figure 1 , a high-power dual-wavelength semiconductor rectangular laser generating device of the present invention, comprising A stack 1, A shaping lens 11, B stack 2, B shaping lens 21, coupling mirror 3, shaping lens 4, reflective focusing mirror 5, air inlet 6. Optical shutter 7, shielding box 8, wherein: the shielding box 8 is a metal rectangular hollow box with a cover; the shielding box 8 is provided with an air inlet 6, and the air inlet 6 is located at the The bottom is connected to the fan output port of the peripheral air purification device; the side wall of the shielding box 8 is provided with a window for laser output called a light gate;

[0027] The A stack 1 is a laser generating element composed of a semiconductor laser chip array; the laser wavelength output by the A stack 1 is 940nm, the output power is 2700W, and the cross section is cylindrical; the direction axis of the laser light emitted by the A stack 1 is called A optical axis;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com