Control method for quickly and accurately positioning steel coil dolly

A steel coil trolley, precise positioning technology, applied in the direction of rolling mill control devices, metal rolling, manufacturing tools, etc., can solve the problem of not considering the influence of the positioning accuracy of the steel coil trolley, so as to avoid manual judgment process and improve automatic control , the effect of avoiding accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The control method of the fast and precise positioning of the steel coil trolley of the present invention, its specific implementation steps are:

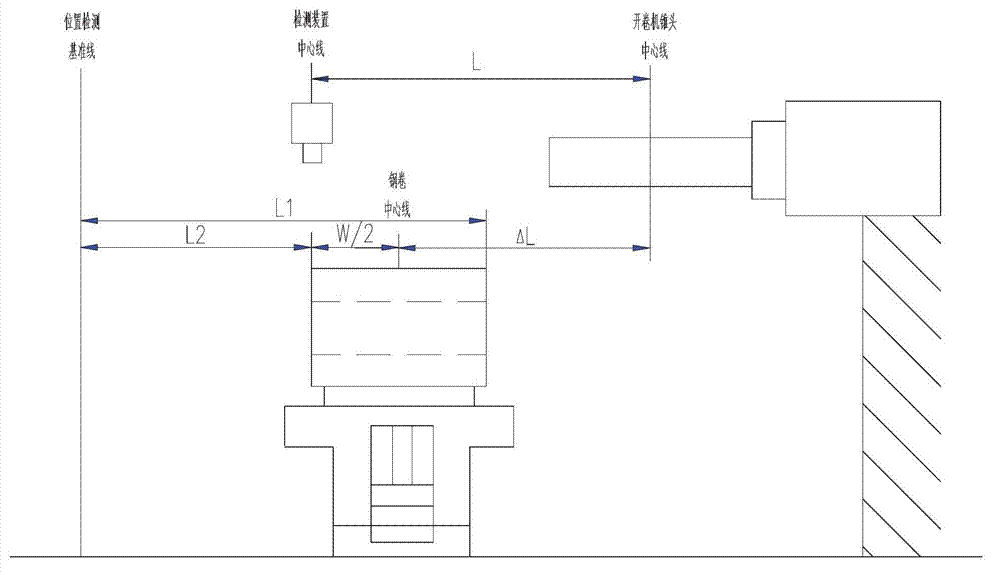

[0034] Step 1: Calculate the set value of the position of the steel coil trolley in the moving direction according to the known equipment parameters and the relevant parameters detected by the position sensor. see figure 1 , the setting value of the moving position of the steel coil trolley, its calculation method is as follows: first calculate the strip width W:

[0035] W=L1-L2

[0036] L1 is the distance detection value of the traveling encoder when the front end of the steel coil reaches the width position detector, and L2 is the distance detection value of the traveling encoder at the end of the width measurement.

[0037] The distance △L that the steel coil trolley needs to travel:

[0038] △L=L-W / 2

[0039] L is the distance between the centerline of the cone head of the uncoiler and the width position detector, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com