Tail gas heat exchanger of diesel engine

A diesel engine and heat exchanger technology, applied in the direction of heat exchanger shell, indirect heat exchanger, heat exchanger type, etc., can solve the problems of exhaust heat energy not being utilized, deterioration of surrounding working environment, waste of heat energy, etc., and achieve production cost Low, improve the working environment, the effect of high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

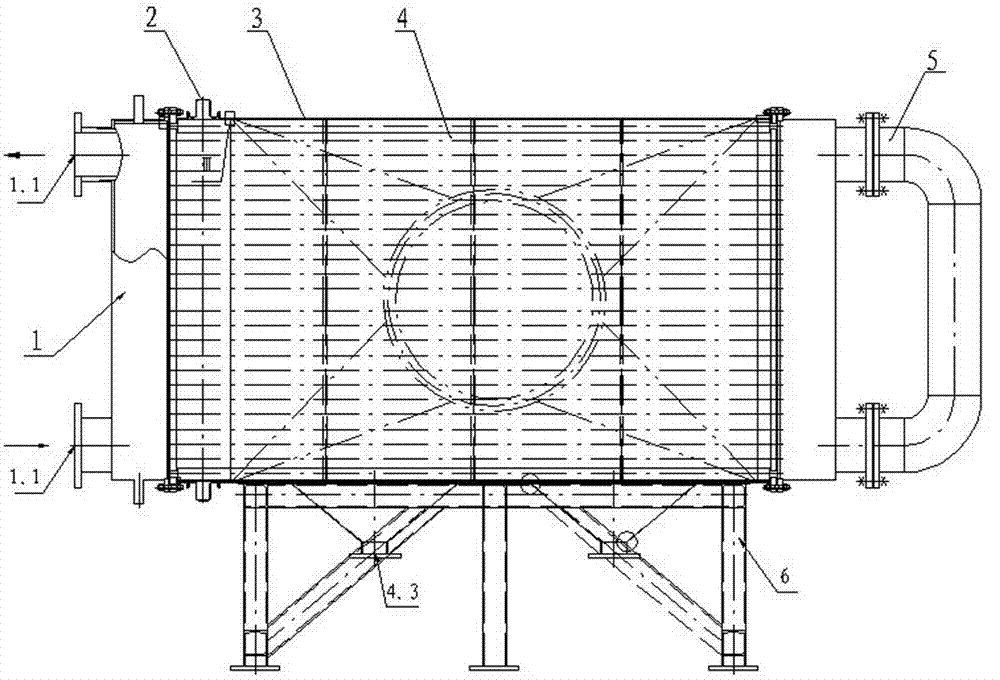

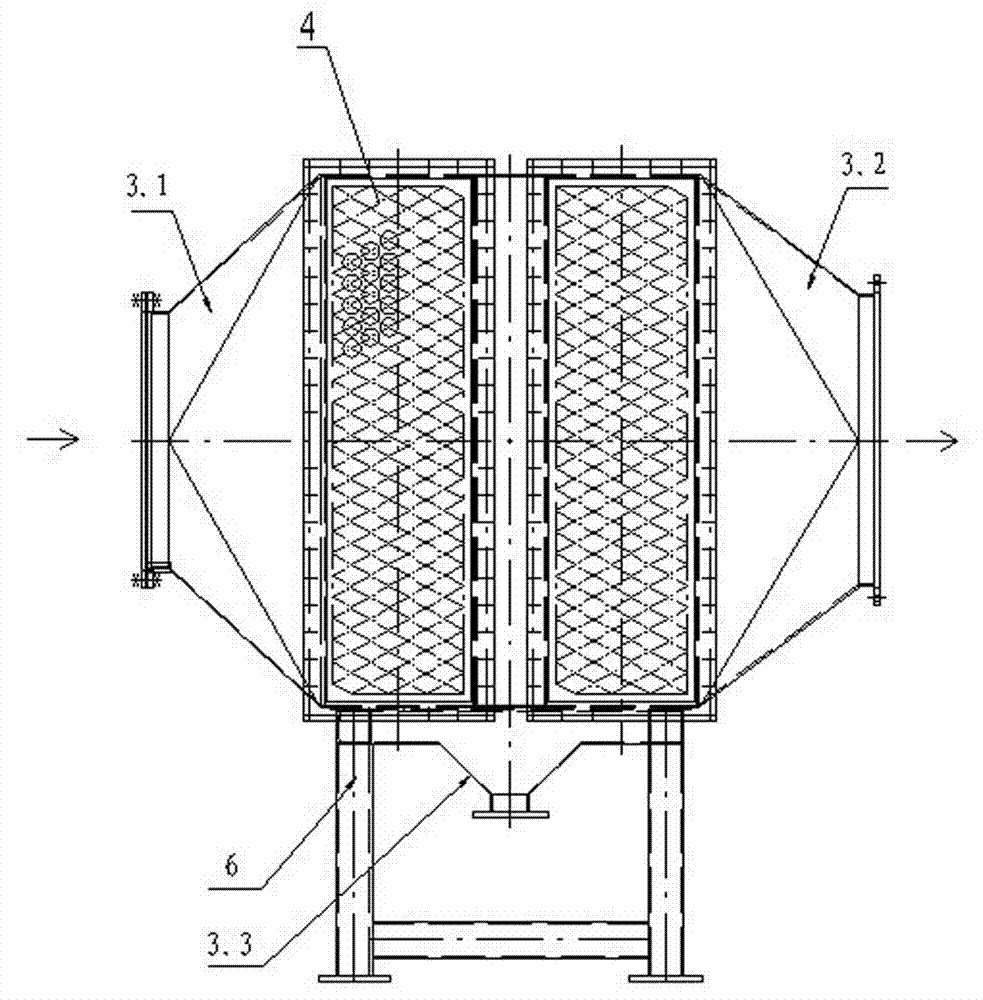

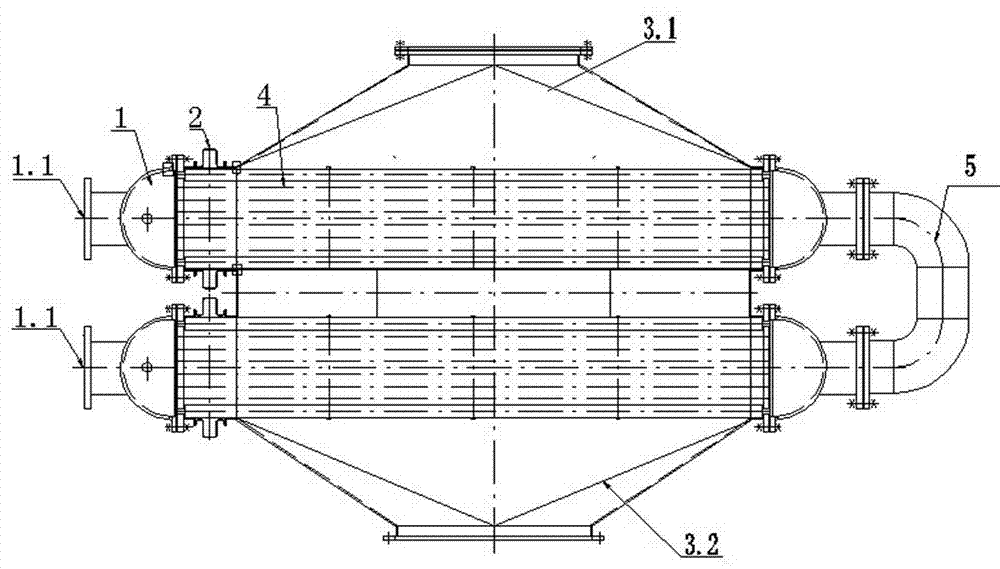

[0015] figure 1 The shown diesel engine exhaust heat exchange device includes a water collection chamber 1 , an expansion joint 2 , an insulation shell 3 , a heat exchange tube assembly 4 , an elbow 5 and a bracket 6 . The water collection chamber 1 is a semicircular groove-shaped cavity, and one end of the outer wall is provided with a connecting pipe 1.1 as a channel for introducing or discharging water flow. The heat exchange tube assembly 4 is a rectangular body in a lying position, the left end surface is sealed and connected to the water collection chamber 1 through the expansion joint 2, and the right end surface is directly sealed and connected to the water collection chamber 1 to form a heat exchanger unit. The heat-insulating shell 3 is a rectangular thin-plate member provided with a heat-insulating layer, and the heat-insula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com