External oil cooling structure of rotary-vane vacuum pump

A rotary vane vacuum pump, external technology, applied in the direction of rotary piston type/oscillating piston type pump components, components of pumping devices for elastic fluid, pump components, etc., can solve the problem that the oil temperature cannot be effectively cooled, vacuum pumps Oxidation and deterioration of oil, affecting the performance of vacuum pumps, etc., to achieve good cooling effect, prolong service life, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

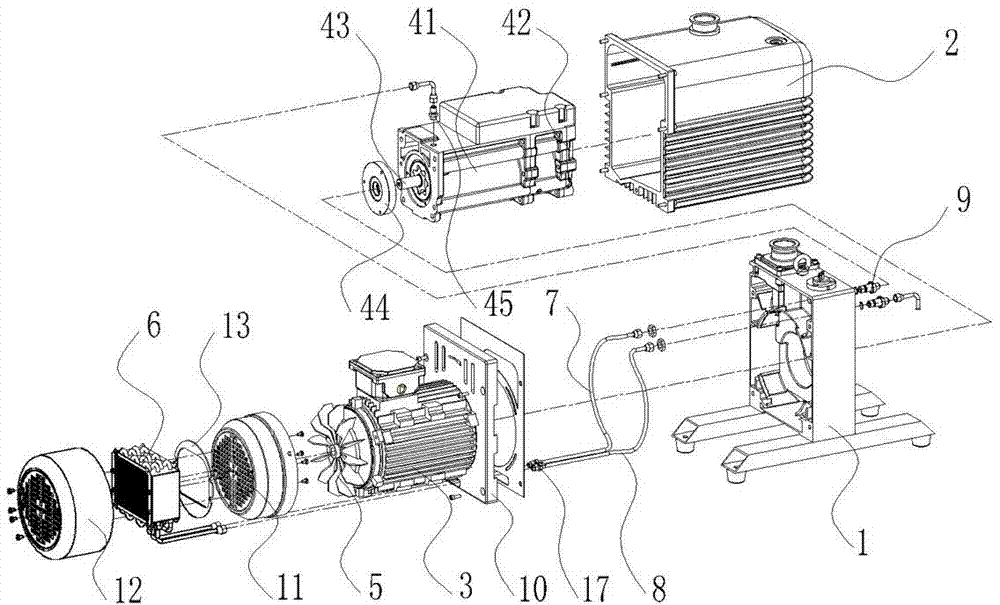

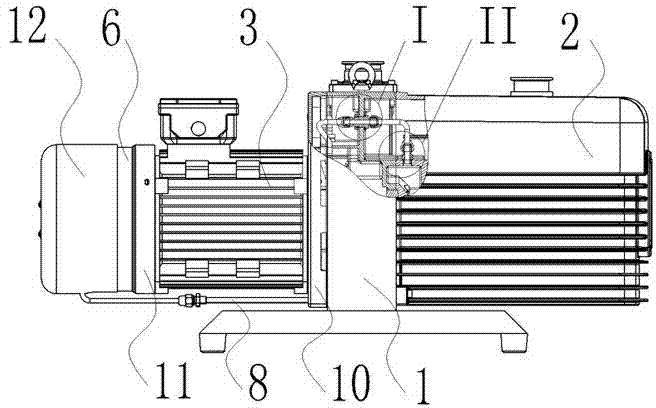

[0024] like figure 1 As shown, taking a two-stage rotary vane vacuum pump as an example, the external oil cooling structure of a rotary vane vacuum pump of the present invention includes a cast aluminum bracket 1 with a shell structure, and an oil tank 2 is fixed on the front side of the bracket 1, and the oil tank The open end of 2 is encapsulated on the front side of the bracket 1, a pump body is installed on the front side of the corresponding bracket 1 in the oil tank 2, and a motor 3 is installed on the rear side of the bracket 1, and the output shaft of the motor 3 extends to the side of the bracket 1. The front side is coaxially connected with the pump rotor in the pump body, and a fan 5 is coaxially installed at the outer end of the motor 3, and the pump body includes the pump stator of the front pump that is coaxially superimposed and fixed on the front side of the bracket 1 in turn. 41. The middle wall, the stator 41 of the back-stage pump and the pump back cover 42...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com