Single-pipe gas relay detecting bench, centering clamping mechanism and detection method thereof

A technology of gas relay and clamping mechanism, which is applied in volume measurement instrument/method, liquid/fluid solid measurement, liquid/vacuum measurement for liquid tightness, etc., can solve the problem of low working efficiency, high labor intensity, Unable to detect problems such as multi-caliber gas relays, to achieve the effect of convenient transformation, low labor intensity and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

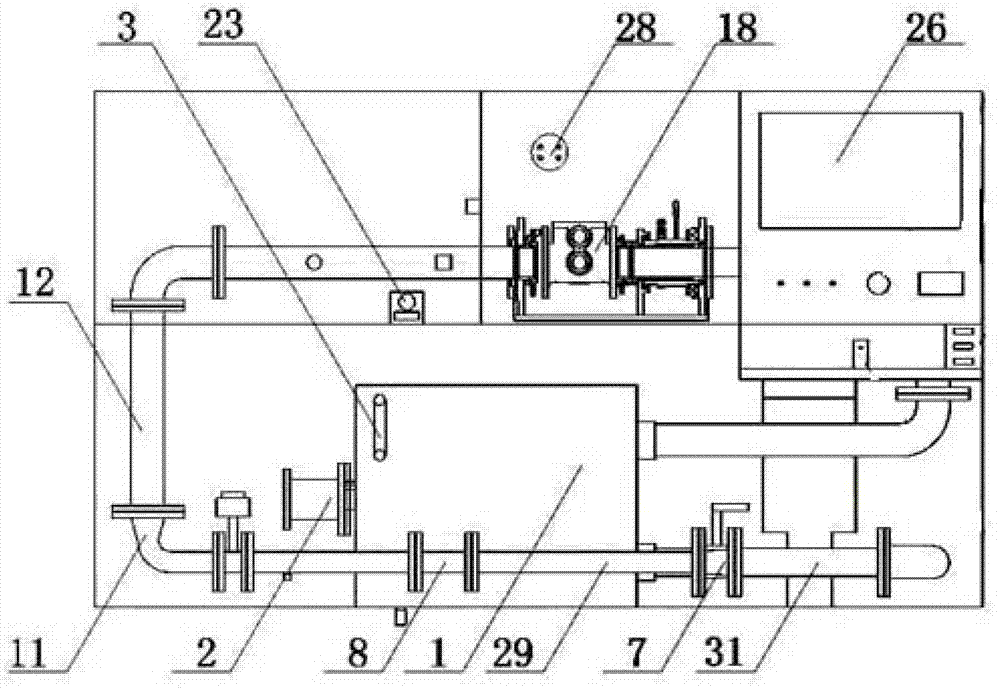

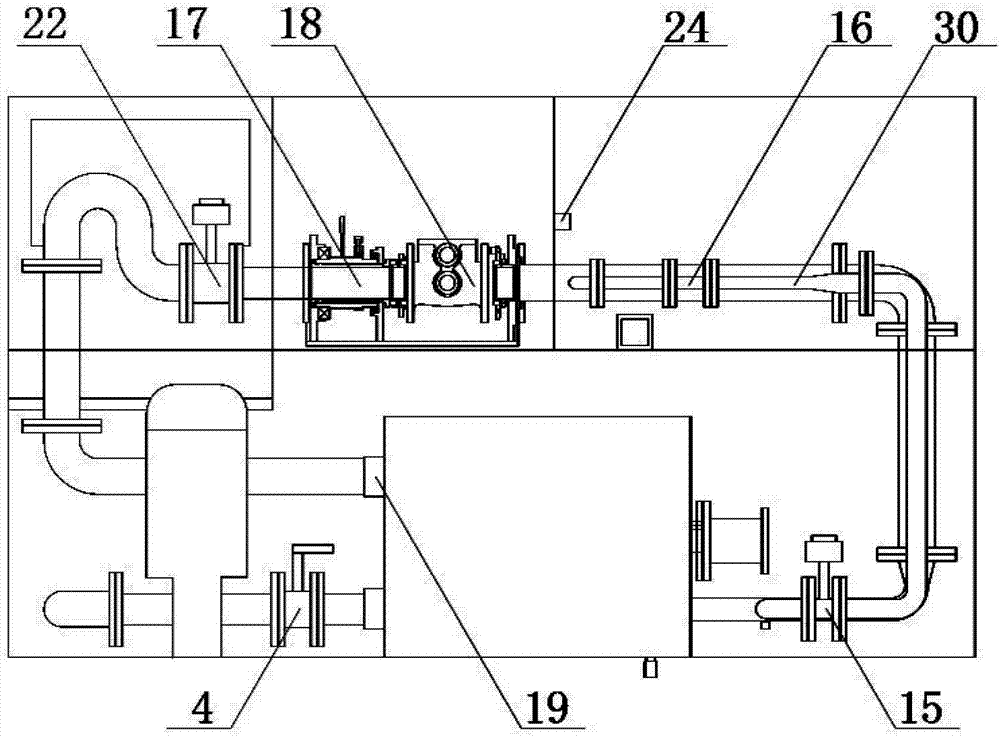

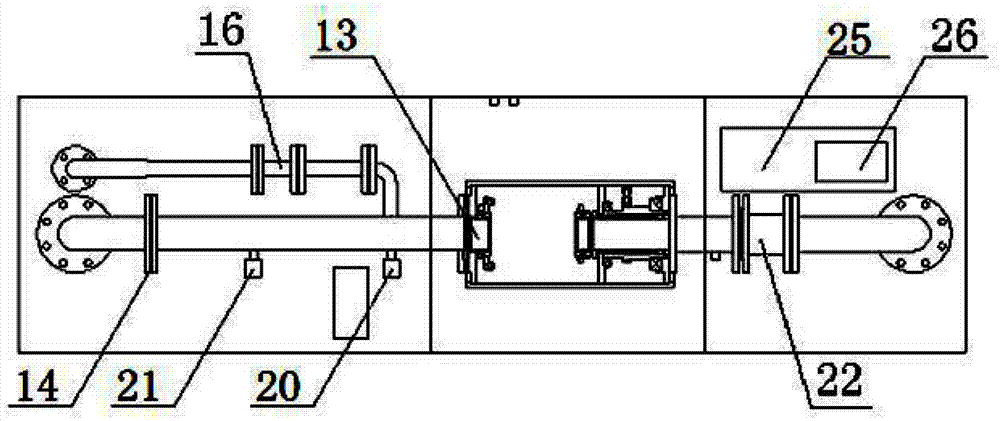

[0112] like Figure 1-11 The shown single-pipe gas relay test bench includes a bench 34 and a fuel tank 1 arranged on the casing, and a heavy gas flow rate test oil circuit connected between the bench 34 and the fuel tank 1;

[0113] A first electromagnetic valve 24 is also installed on the casing, the outlet end of the first electromagnetic valve 24 is connected to the atmosphere, and the inlet end of the first electromagnetic valve 24 is used to be connected with the gas nozzle on the gas relay 18 to be tested. ;

[0114] The centering clamping mechanism is provided on the platform 34; the centering clamping mechanism includes a fixed end 13 and a moving end 17 which are arranged on the platform 34 for clamping the gas relay 18 to be tested; the fixed end 13 is a base fixed on the stand 34, and the fixed end 13 is provided with a fixed end jack 64; the moving end 17 is installed on the clamp on the stand 34, and the clamp is used to make the moving end 17 moves forward or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com