Method for measuring pollen density by improved density gradient centrifugation method

A technology of density gradient centrifugation and concentration gradient, applied in the field of plant physiology, can solve the problems of no relevant reports on the determination of pollen density, difficulty in collecting pollen, inconvenient operation, etc., and achieve the effect of simple operation, small sample amount and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

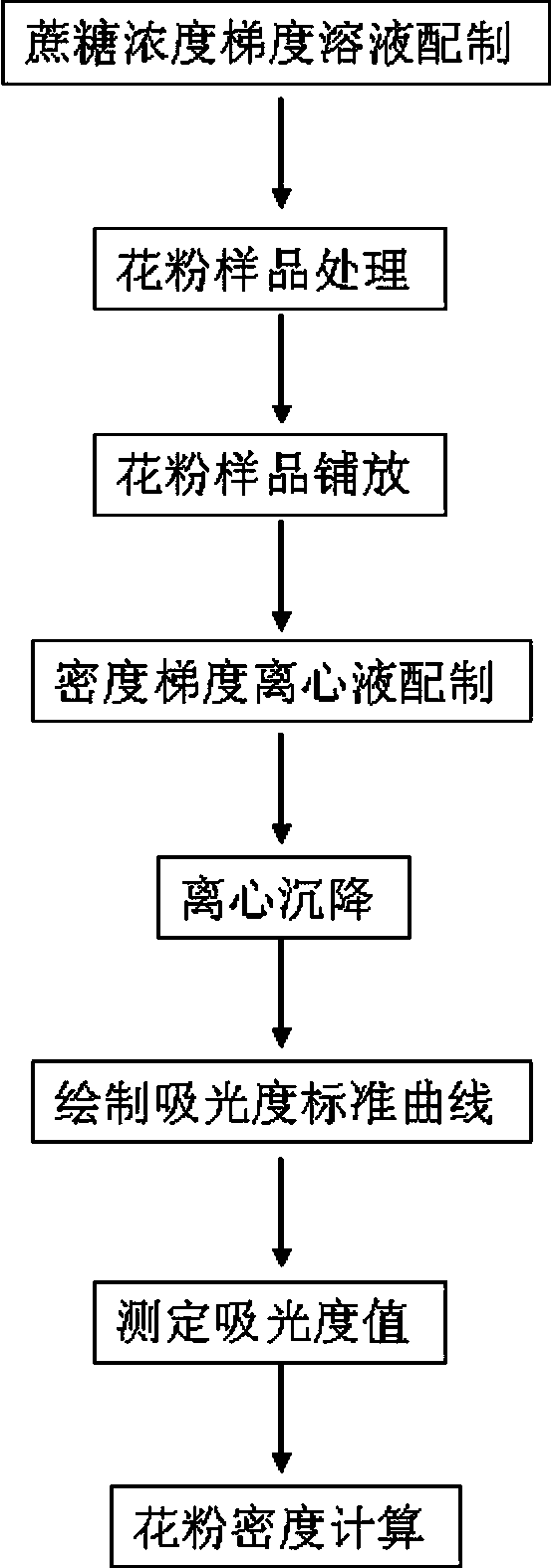

Method used

Image

Examples

Embodiment 1

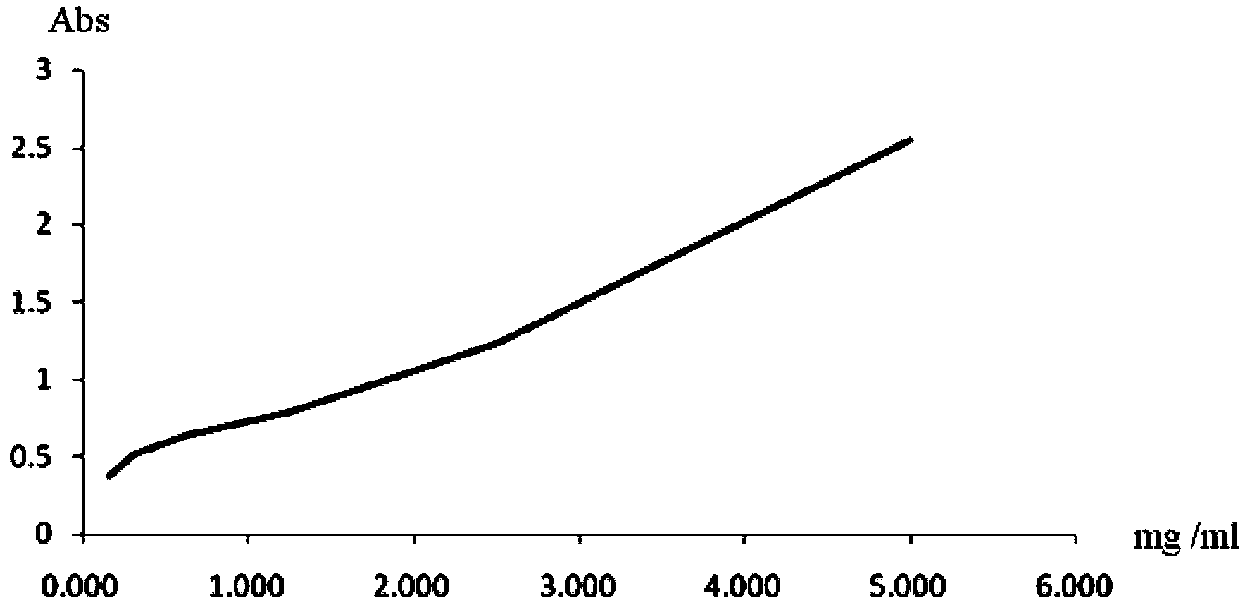

[0057] Determination of pollen density of tobacco N. alata.

[0058]First, prepare sucrose solutions with mass percentages of 10%, 20%, 30%, 40%, 45%, 50%, 55%, 60%, 65%, and 70%, respectively, and place them in beakers for later use. Secondly, weigh 0.001g N.alata pollen and mix it in 100μl 10% sucrose solution. Again, first use a syringe to add 100 μl of 10% sucrose solution containing pollen samples to the bottom of a 1.5ml centrifuge tube, then draw the high-concentration sucrose solution, insert the syringe into the bottom of the tube, add high-concentration sucrose solution, and wait until the concentration of the solution is high. From the top of the lower solution to the upper layer, add 150 μl each of 20%, 30%, 40%, 50%, 55%, 60% and 65% sucrose solution in turn according to the above method to make a density gradient centrifugal solution of 10%~65% . In a Microfuge 22R centrifuge, at 20°C, at a speed of 6000rpm, centrifuge for 10 minutes and then let it stand still...

Embodiment 2

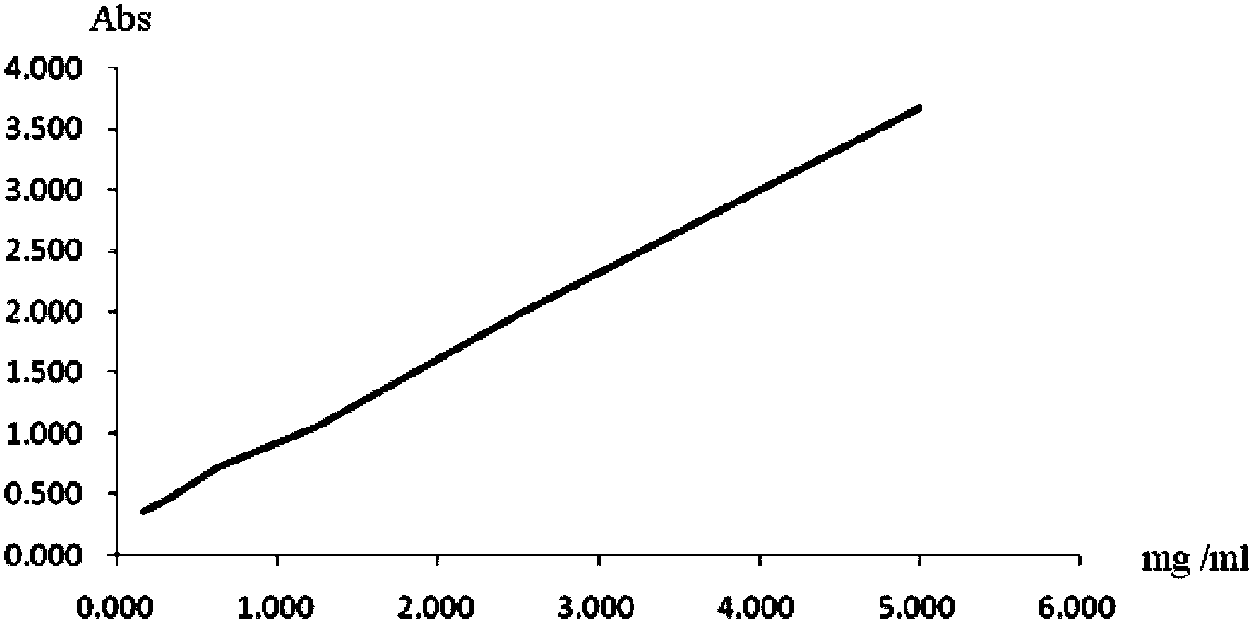

[0073] Determination of pollen density of tobacco variety N. rustica.

[0074] First, prepare sucrose solutions with mass percentages of 10%, 20%, 30%, 40%, 45%, 50%, 55%, 60%, 65%, and 70%, respectively, and place them in beakers for later use. Secondly, weigh 0.01g N.rustica pollen and mix it in 1000μl 10% sucrose solution. Again, first add 100 μl of 10% sucrose solution containing pollen samples to the bottom of the 2.0ml centrifuge tube with a syringe, then draw the high-concentration sucrose solution, insert the syringe into the bottom of the tube, add the high-concentration sucrose solution, and wait until the concentration of the solution is high From the top of the lower solution to the upper layer, add 200 μl each of 20%, 30%, 40%, 50%, 55%, 60% and 65% sucrose solution in turn according to the above method to make a 10%~65% density gradient centrifugal solution . In a Microfuge 22R centrifuge, at 20°C, at a speed of 4000rpm, centrifuge for 15 minutes and then let i...

Embodiment 3

[0089] Determination of pollen density of tobacco variety N. repanda.

[0090] First, prepare sucrose solutions with mass percentages of 10%, 20%, 30%, 40%, 45%, 50%, 55%, 60%, 65%, and 70%, respectively, and place them in beakers for later use. Secondly, weigh 0.005g N.repanda pollen and mix it in 500μl 10% sucrose solution. Again, first use a syringe to add 50 μl of 10% sucrose solution containing pollen samples to the bottom of the 1.5ml centrifuge tube, then draw the high-concentration sucrose solution, insert the syringe into the bottom of the tube, add high-concentration sucrose solution, and wait until the concentration of the solution is high. From the top of the lower solution to the upper layer, add 50 μl each of 20%, 30%, 40%, 50%, 55%, 60% and 65% sucrose solution in turn according to the above method to make a 10%~65% density gradient centrifugal solution . In a Microfuge 22R centrifuge, at 20°C, at a speed of 10,000rpm, centrifuge for 5 minutes and then let it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com