Method for locally burying PCB (Printed Circuit Board) daughter board in PCB

A printed circuit board and sub-board technology, which is applied in the direction of assembling printed circuits with electrical components, can solve problems such as size increase, large-scale equipment and process difficulties, and cost increase, so as to improve the bonding force and reduce the total cost of PCB design. The number of layers and the total thickness of the PCB, the effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

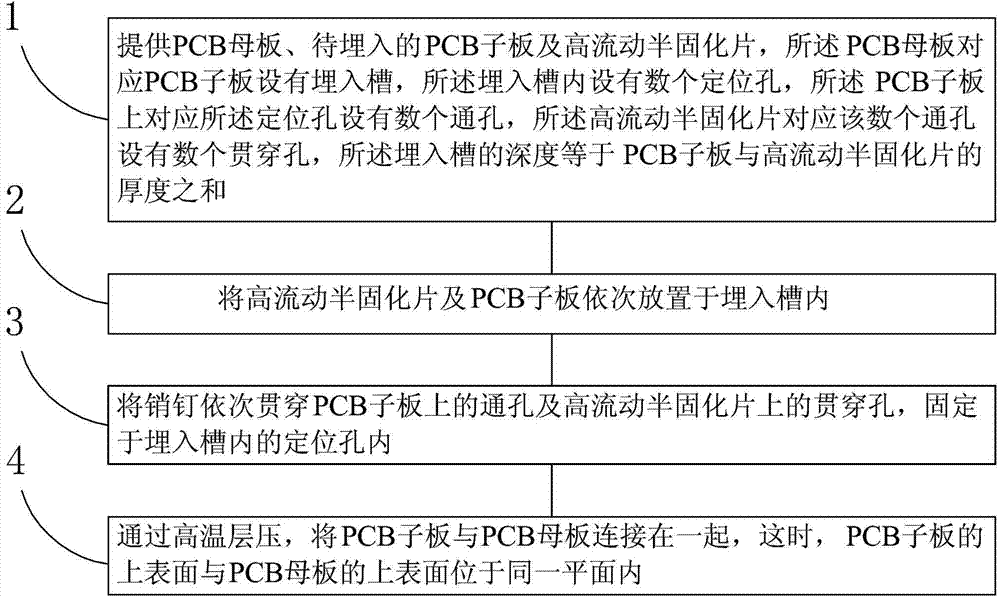

[0028] see Figure 1 to Figure 5 , the present invention provides a method for partially embedding a printed circuit board into a PCB sub-board, comprising the following steps:

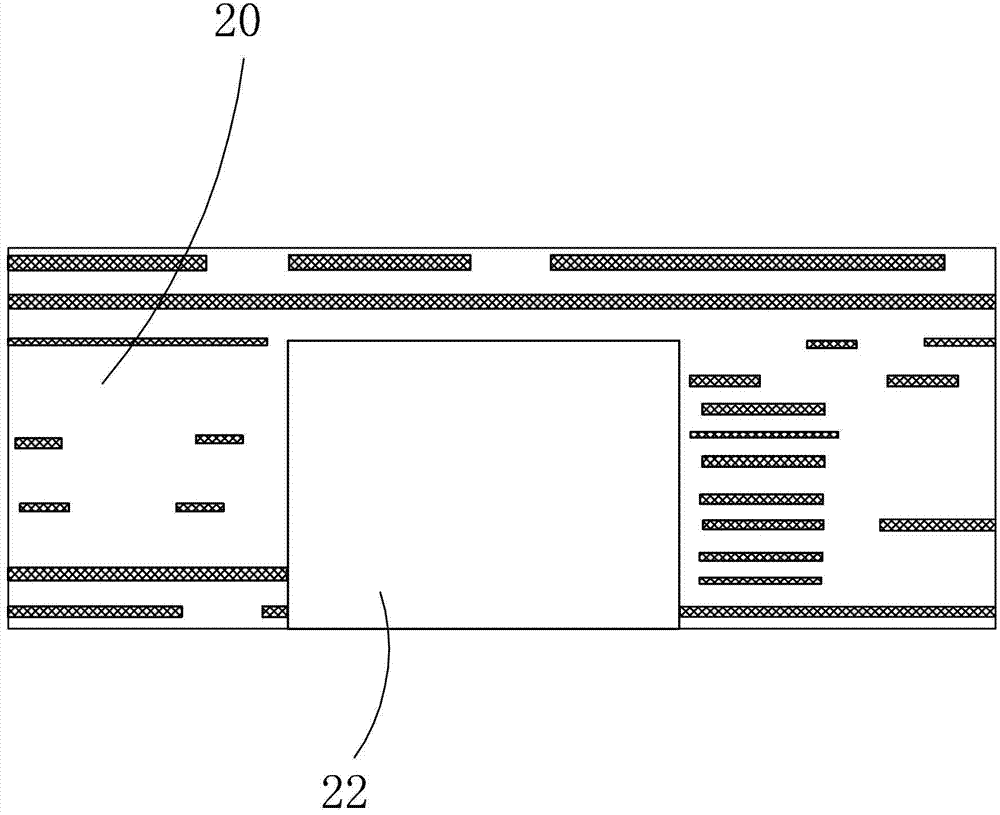

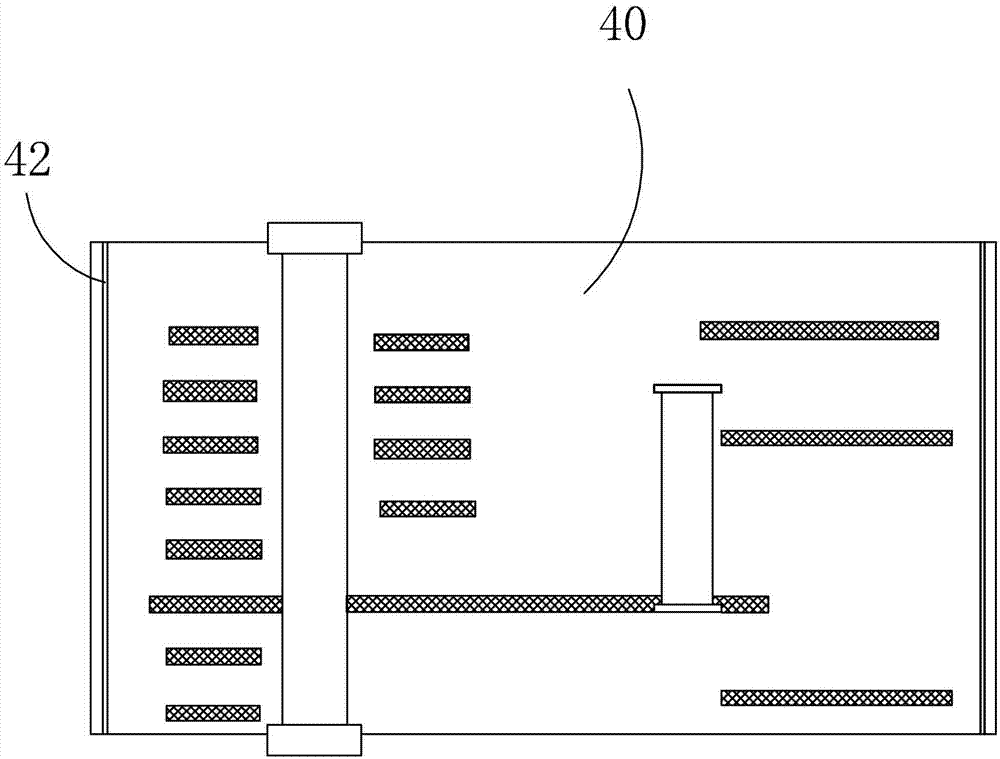

[0029] Step 1. Provide PCB motherboard 20, PCB sub-board 40 to be embedded and high-flow prepreg 60. The PCB motherboard 20 is provided with an embedding groove 22 corresponding to the PCB sub-board 40, and the embedding groove 22 is provided with several positioning holes (not shown), the PCB sub-board 40 is provided with several through holes 42 corresponding to the positioning holes, and the high flow prepreg 60 is provided with several through holes corresponding to the several through holes 42 (not shown in the figure). ), the depth of the buried groove 22 is eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com