Multi-channel compound heat radiating sealing chassis

A compound sealing and multi-channel technology, which is applied in the field of electronic equipment, can solve the problems of large thermal resistance and poor heat dissipation performance, and achieve the effects of increasing heat exchange area, low thermal resistance path, and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

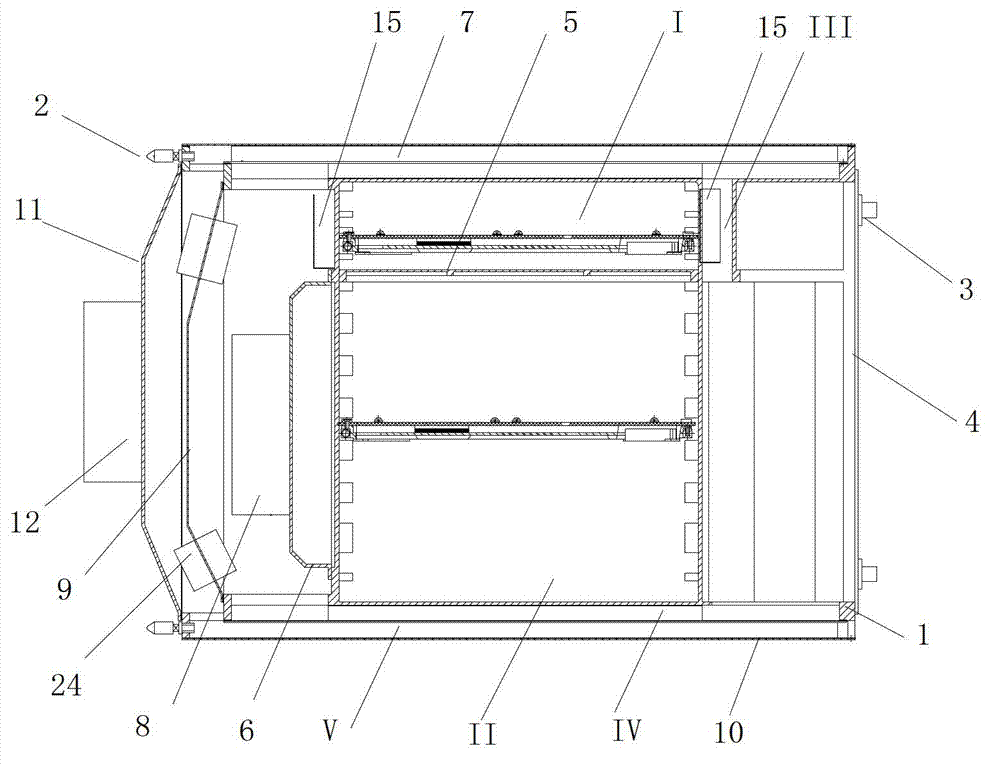

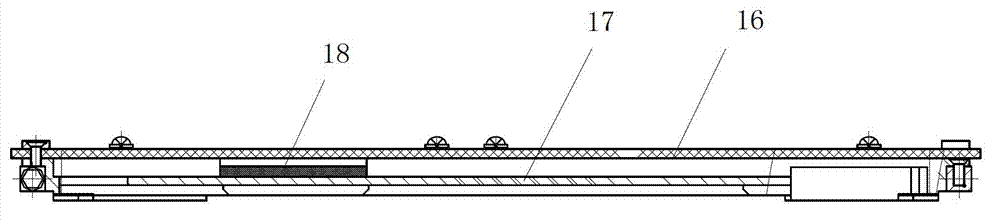

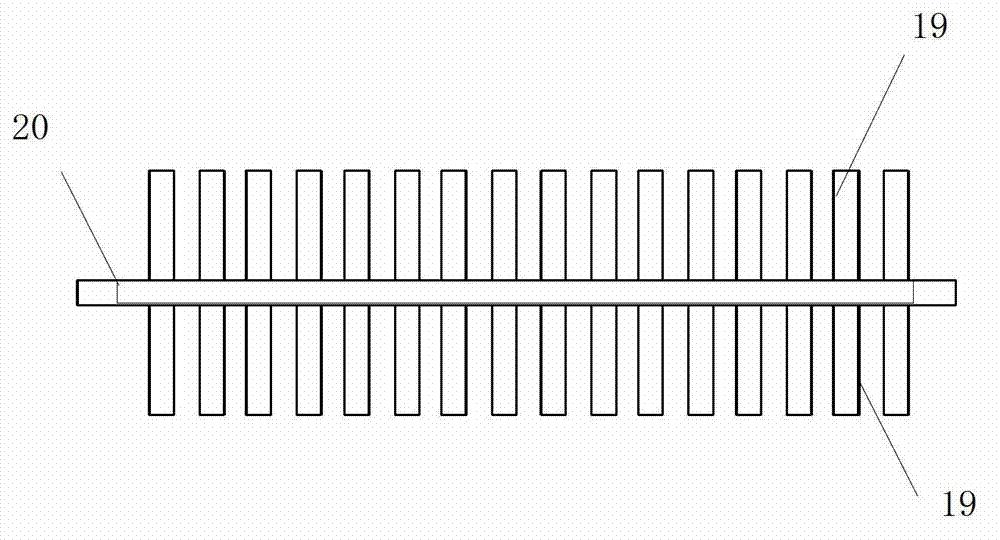

[0023] The working principle of this multi-channel compound heat dissipation sealed chassis is: based on the compound channel heat dissipation mode of the inner and outer double-fin structure, the cooling method combining conduction and forced air cooling is adopted. Both sides of the chassis are double-layered, and the heat of the internal modules is brought into the first channel by means of the inner fan cooling and side wall conduction. Heat away.

[0024] The chassis is mainly composed of chassis frame, side heat exchange plate, inner partition plate, rear end heat exchange plate, outer sealing plate, rear sealing plate, front panel and upper and lower cover plates. When the requirements for electromagnetic compatibility are high, a shielding plate can be installed at the bottom of the chassis to reduce the influence of motherboard and cable radiation on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com