Manufacture method for micropore wiredrawing die and manufacture mould

A technology for making molds and wire drawing dies, which is applied in the field of microporous wire drawing dies and its manufacturing method to make molds, to achieve the effects of increased service life, high pass rate, and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

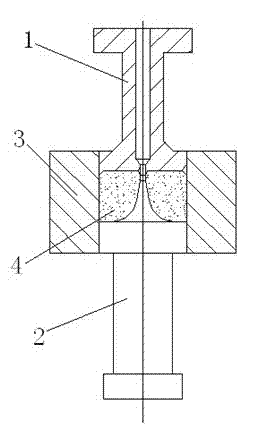

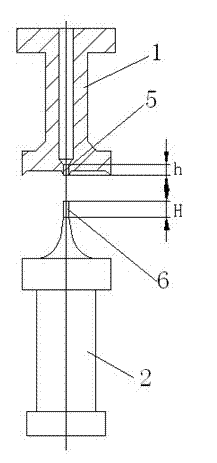

[0032] The present invention will be further described below with reference to the accompanying drawings and embodiments.

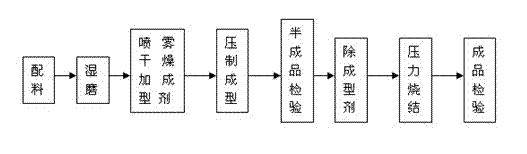

[0033] As can be seen from the accompanying drawings, the present invention relates to a method for making a microporous metal wire drawing die, using tungsten carbide (WC) as the main material, adding appropriate amounts of titanium carbide (TaC) and cobalt (Co), tungsten carbide (WC) and The weight percentage of titanium carbide (TaC) and cobalt (Co) is 93-95%: 1.5-1.8%: 3.5-4.5%; after mixing the above-mentioned raw materials according to the proportion, after wet grinding, the overall grinding particle size of the mixture is less than 2 -3μm powder, then add spray drying molding agent for spray drying, and then send it into a pressing mold for compression molding to make a semi-finished product. After passing the inspection, remove the molding agent, and finally send it into a sintering furnace for sintering and molding to produce a microporous metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com