Hybrid power loop based on machine-hydraulic joint energy regeneration

An energy regeneration, hybrid technology, applied in hybrid vehicles, fluid hybrid vehicles, motor vehicles, etc., can solve the problems affecting the driving performance and comfort of vehicles, the fast release speed of hydraulic energy storage devices, and the ratio of hydraulic energy storage devices. problems such as low energy, to achieve the effect of improving driving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

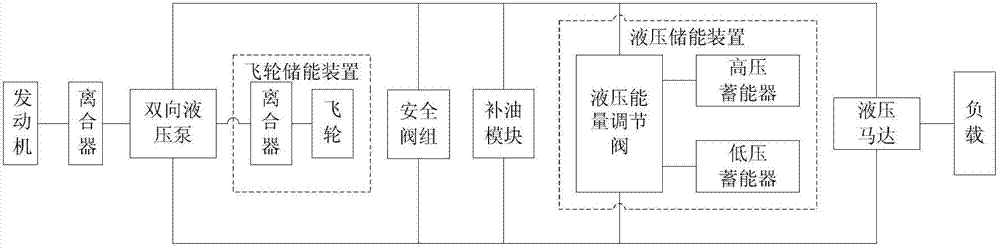

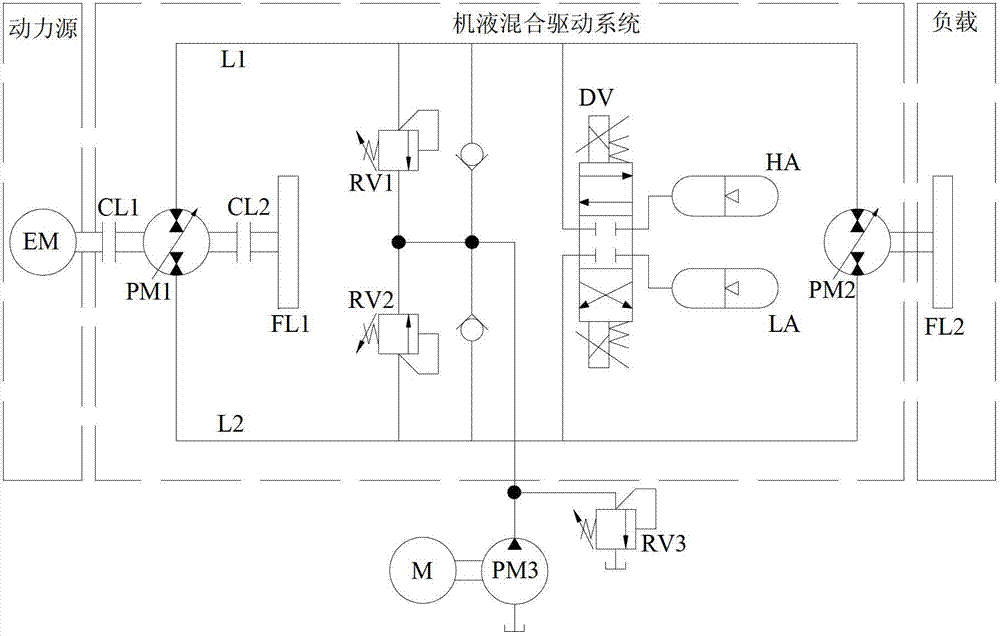

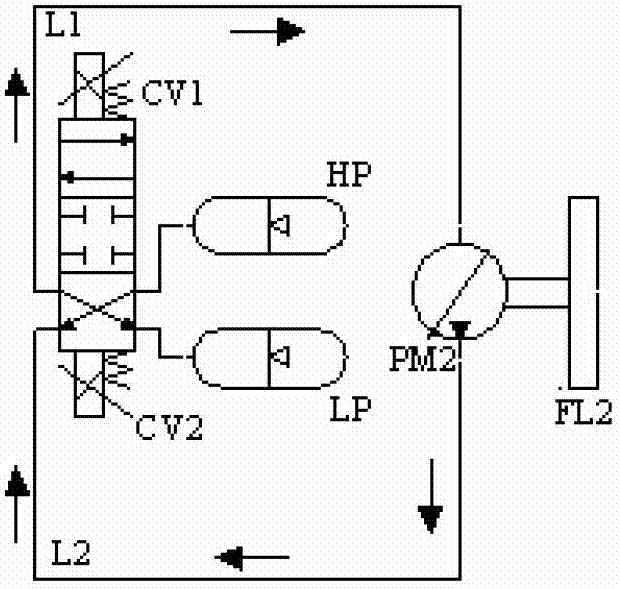

[0023] Such as figure 2 As shown, a hybrid power circuit with machine-hydraulic combined energy regeneration includes an engine EM, a two-way hydraulic pump / motor PM1, a flywheel energy storage device, a safety valve group, an oil supplement module, a hydraulic energy storage device, and a hydraulic motor PM2. The output shaft of the engine EM is connected to the input shaft of the first clutch CL1, the output shaft of the first clutch CL1 is connected to the input shaft of the two-way hydraulic pump / motor PM1, the output shaft of the two-way hydraulic pump / motor PM1 is connected to the input shaft of the second clutch CL2 connection, the output shaft of the second clutch CL2 is connected to the flywheel FL1, the safety valve group, the oil supply module, and the hydraulic motor are connected across the closed circuit, the hydraulic motor PM2 is connected to the load FL2, and the main circuit between the oil supply module and the hydraulic motor Bridge the hydraulic energy st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com