Preparation method and preparation system of environment-friendly sterile straw mattress

A preparation system and straw technology, applied in the production of furniture covers, household utensils, loose filling materials, etc., can solve the problems that the glue is prone to mildew, reduces product elasticity, and cannot be recycled, so as to save net laying and carding Process, improve efficiency, good overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the content of the present invention more comprehensible, further description will be made below in conjunction with the accompanying drawings and specific embodiments.

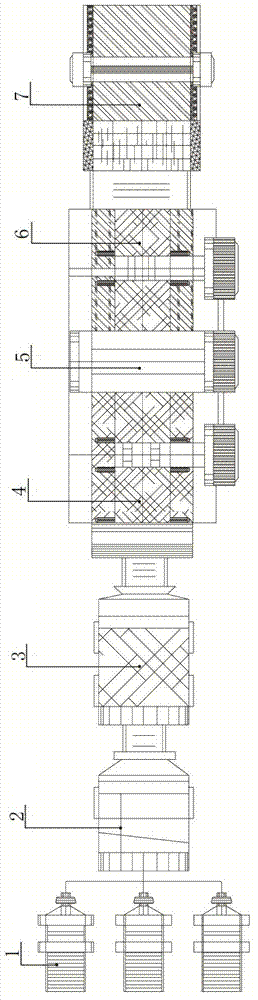

[0024] combine figure 1 The preparation system shown, the preparation method of environment-friendly aseptic straw mattress comprises the following steps:

[0025] 1). Raw material feeding: Feed straw, low-melting point sheath-core fiber and three-dimensional hollow fiber into the opening device; the ratio of each raw material can be set according to needs, and the invention provides a mattress product that can make the final product more comfortable Durable ratio, specifically the ratio of straw, low-melting skin-core fiber and three-dimensional hollow fiber raw material: 4:3:3.

[0026] When the present invention is applied, the raw material enters the preparation system through the raw material feeding device 1, and the quantity of the raw material feeding device 1 can be set to on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com