Apparatus and method for hydrogen production through methanol steam reforming

A technology of steam reforming and hydrogen production equipment, which is applied in the field of methanol steam reforming hydrogen production equipment, hydrogen production equipment, and methanol steam reforming hydrogen production, which can solve waste of resources, reduce conversion rate, affect the environment and people Health and other issues to achieve the effect of reducing pollution and improving conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

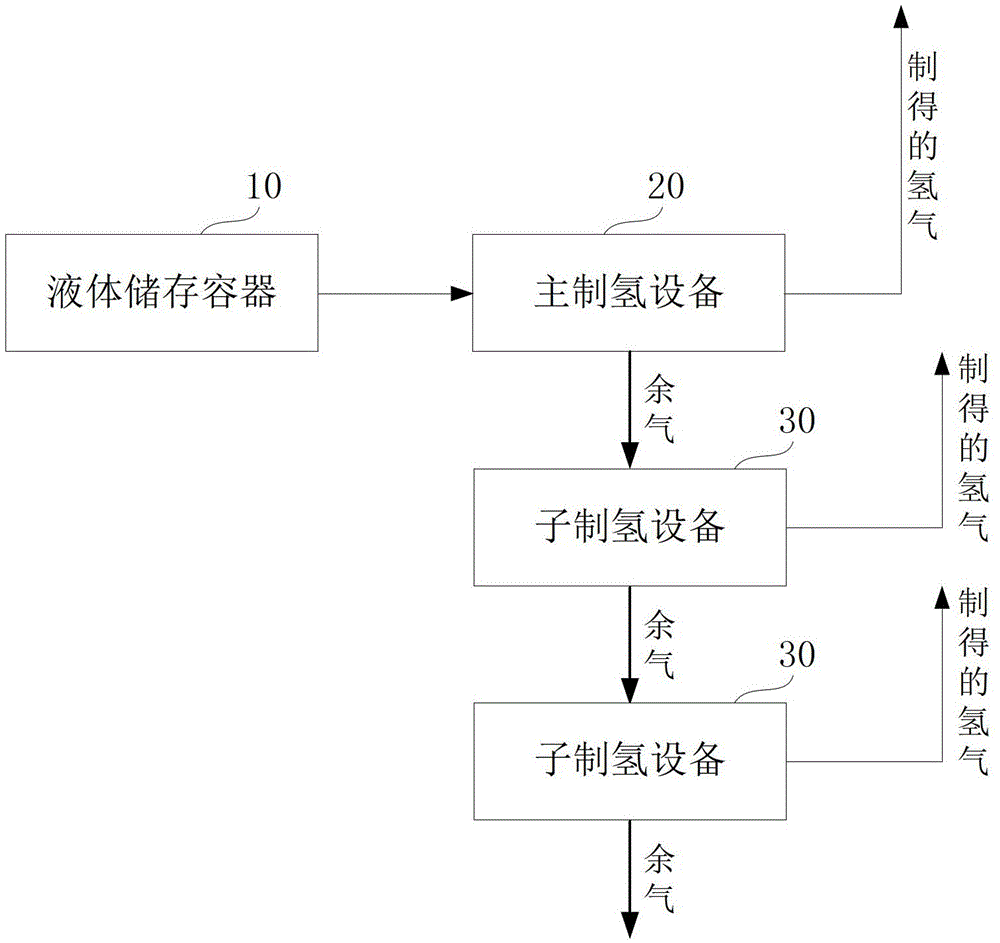

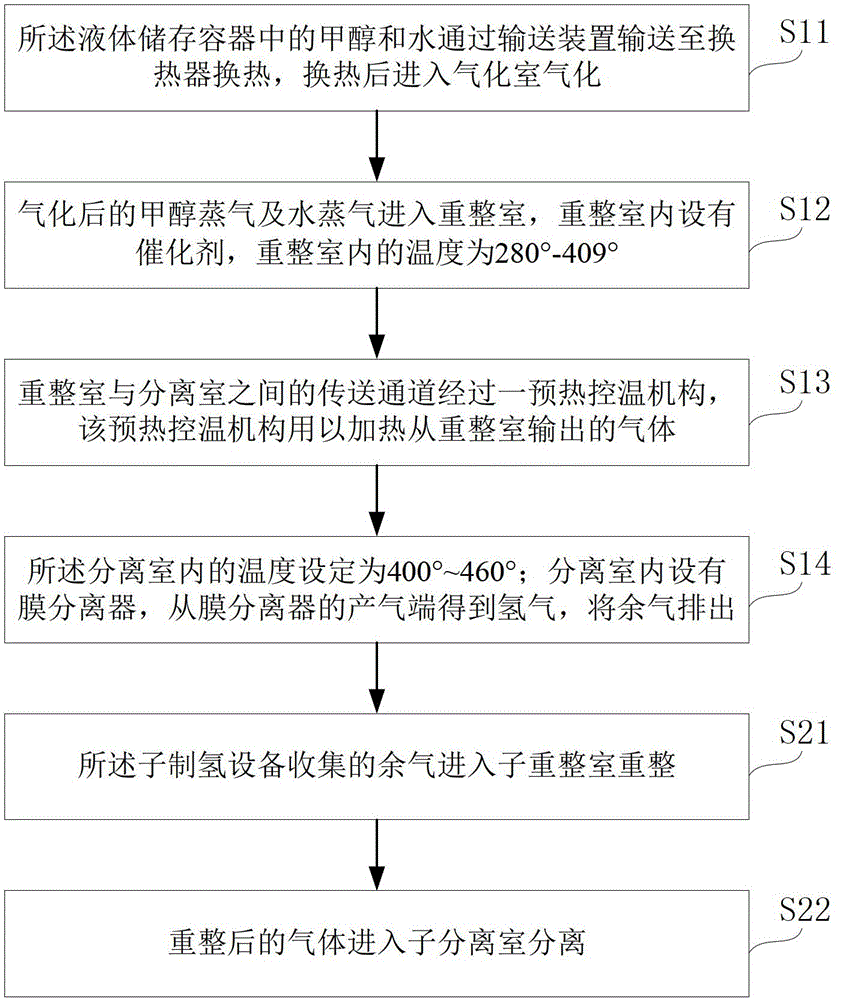

[0066] see figure 1 , the present invention discloses a methanol steam reforming hydrogen production equipment, the hydrogen production equipment includes: a liquid storage container 10, a main hydrogen production equipment 20, one or more sub-hydrogen production equipment 30.

[0067] The main hydrogen production equipment 20 includes: a heat exchanger, a gasification chamber, a reforming chamber, and a separation chamber; the liquid storage container, heat exchanger, vaporization chamber, reforming chamber, and separation chamber are connected in sequence through pipelines.

[0068] The methanol and water in the liquid storage container 10 are transported to the heat exchanger through the conveying device for heat exchange, and then enter the vaporization chamber for vaporization after heat exchange. The vaporized methanol vapor and water vapor enter the reforming chamber, where a catalyst is installed, and the temperature in the reforming chamber is 280°-409°.

[0069] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com