Multifunctional composite sewage purifier

A purifier, multi-functional technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. problems, to achieve the effect of reducing blockage, reducing processing workload, and strong equipment selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

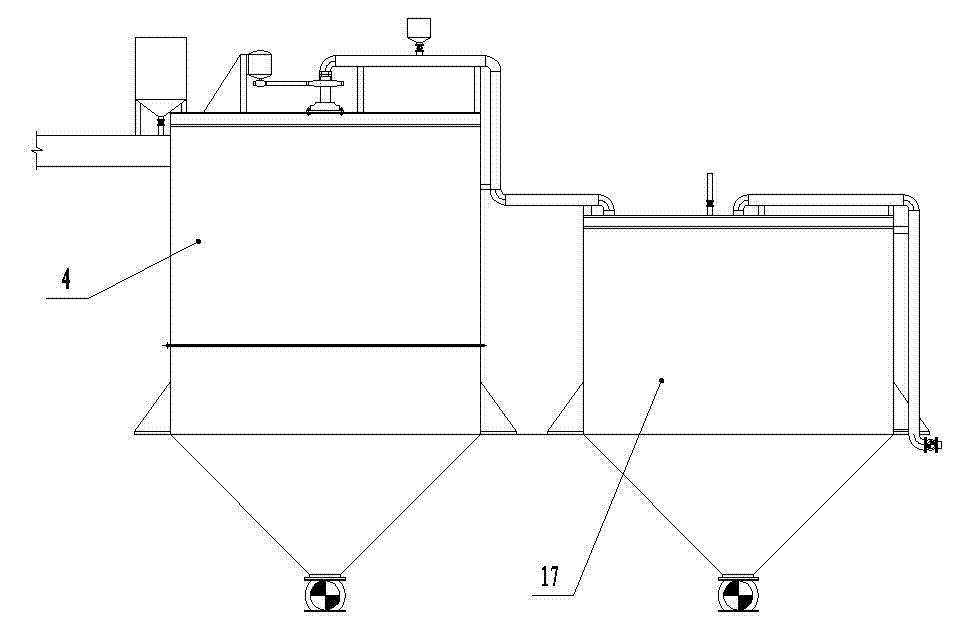

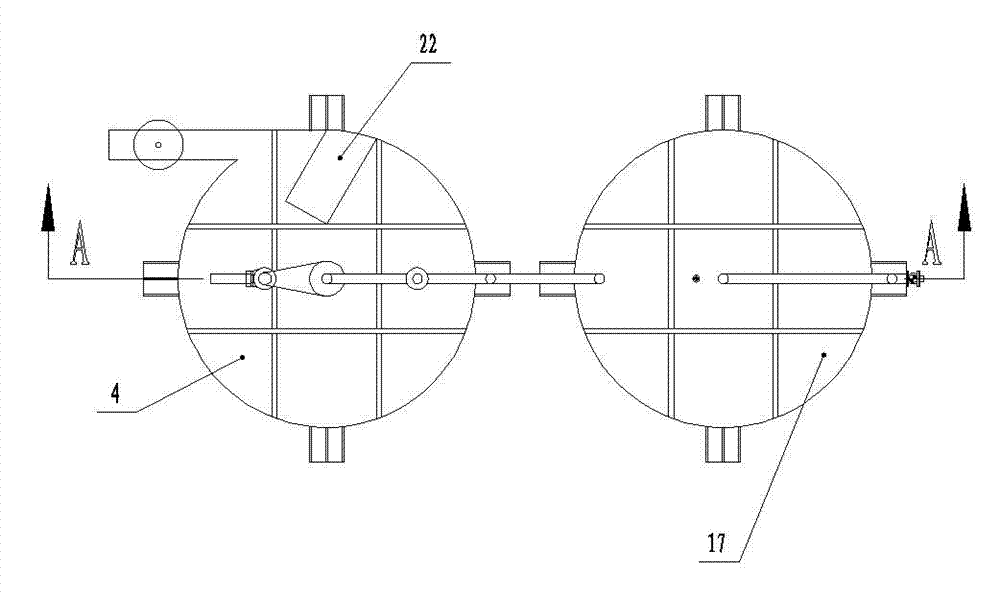

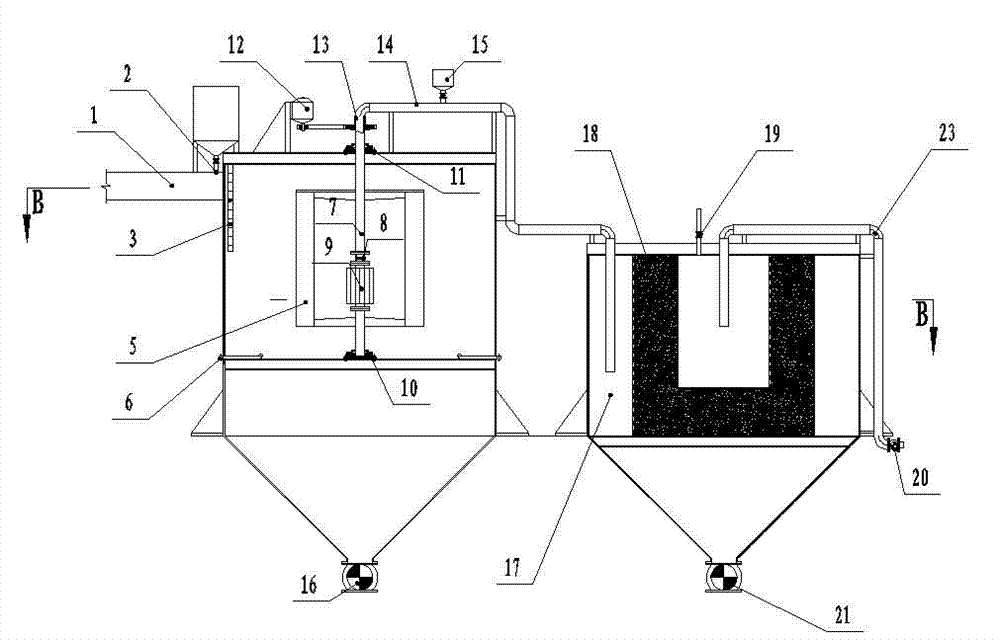

[0029] A kind of multifunctional composite sewage purifier described in present embodiment 1, as figure 1 , figure 2 , image 3 , Figure 4 As shown, it is composed of a centrifugal separation device 4 and a sedimentation filtration separation device 17 connected to the water outlet of the centrifugal separation device. A sewage inlet 1 is provided on the outside of the upper part of the centrifugal separation device. A power transmission group 12 is provided on the top of the centrifugal separation device. The group drives the centrifugal rotor 5 and the aeration device 6 in the centrifugal separation device. The power transmission group is a motor transmission structure; the sedimentation filtration separation device is provided with a U-shaped filter layer 18, an exhaust valve 19, and the top and bottom surfaces of the filter layer Respectively close to the inner top surface and the inner bottom surface of the precipitation filtration separation device, which forms a cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com