Composite foam stabilizer and preparation method thereof

A preparation method and foam stabilizer technology, applied in the field of building materials, can solve the problems of restricting the application and development of foam concrete, low strength and uneven quality of foam concrete, and achieve improved strength and waterproof performance, uniform and fine foam, and high quality stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

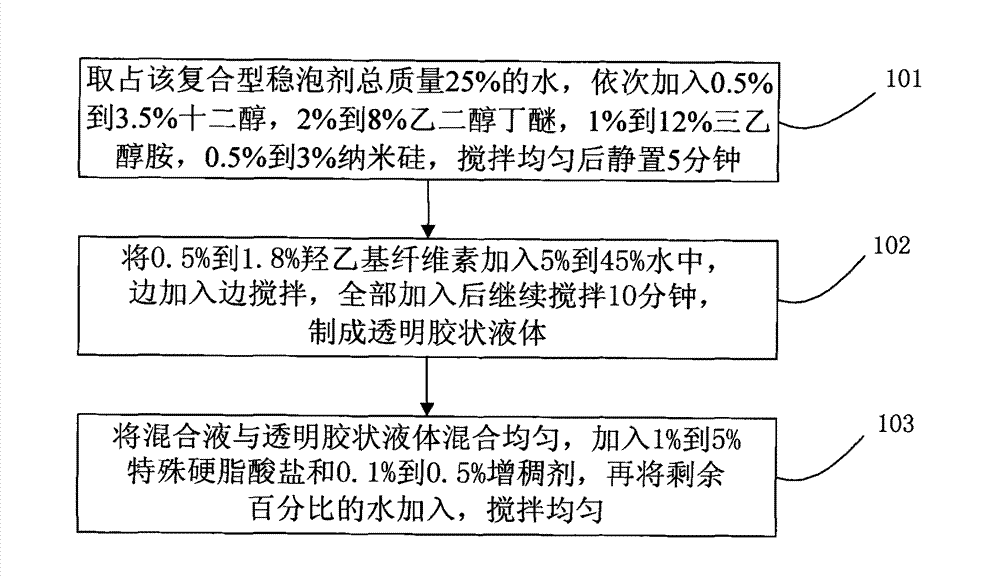

[0021] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0022] In the technical solution of the present invention, the composite foam stabilizer suitable for surfactant foaming agents includes lauryl alcohol, ethylene glycol butyl ether, triethanolamine, hydroxyethyl cellulose, nano silicon, special stearic acid Salt, thickener and water.

[0023] The percentages of lauryl alcohol, butyl glycol ether, triethanolamine, hydroxyethyl cellulose, nano silicon, special stearate, thickener and water to the total mass of the composite foam stabilizer are: lauryl alcohol 0.5% to 3.5%, ethylene glycol butyl ether 2% to 8%, triethanolamine 1% to 12%, hydroxyethyl cellulose 0.5% to 1.8%, nano silicon 0.5% to 3%, special Stearate is 1% to 5%, thickener is 0.1% to 0.5%, and water is the remaining percentage.

[0024] Preferably, the percentages of lauryl alcohol, bu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com