Integrated shale oil separating system

A separation system and shale oil technology, applied in the separation method, filtration separation, liquid separation, etc., can solve the problems of increased production cost, filtration purity to be improved, etc., to achieve improved separation purity, less environmental constraints, and good separation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

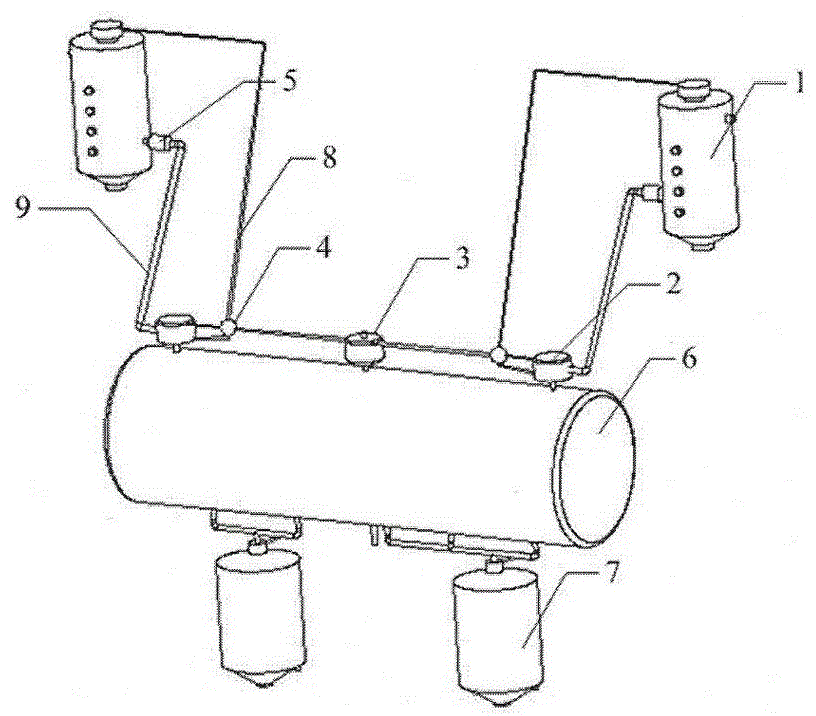

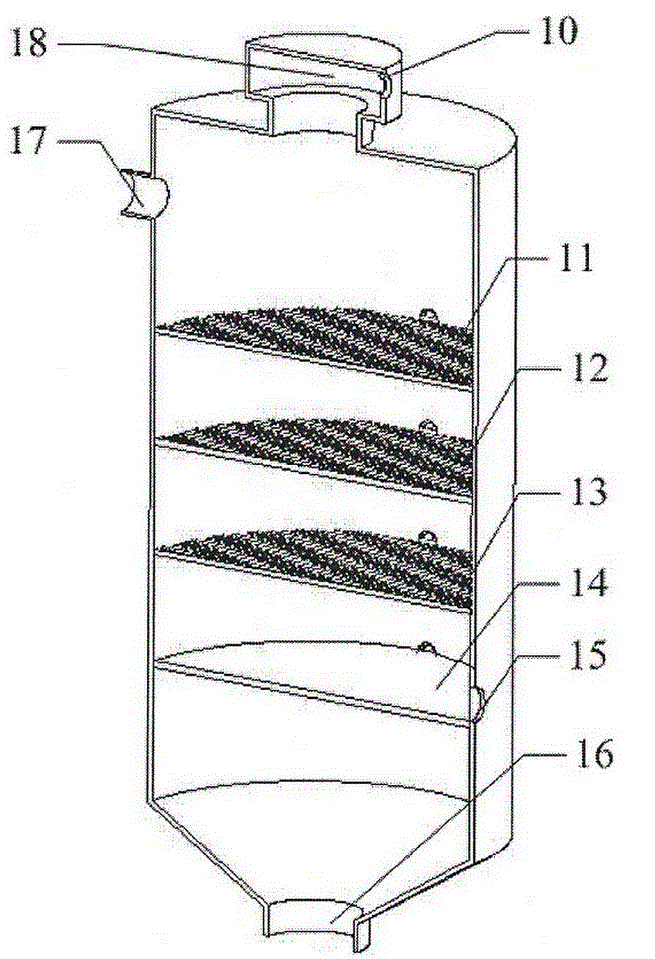

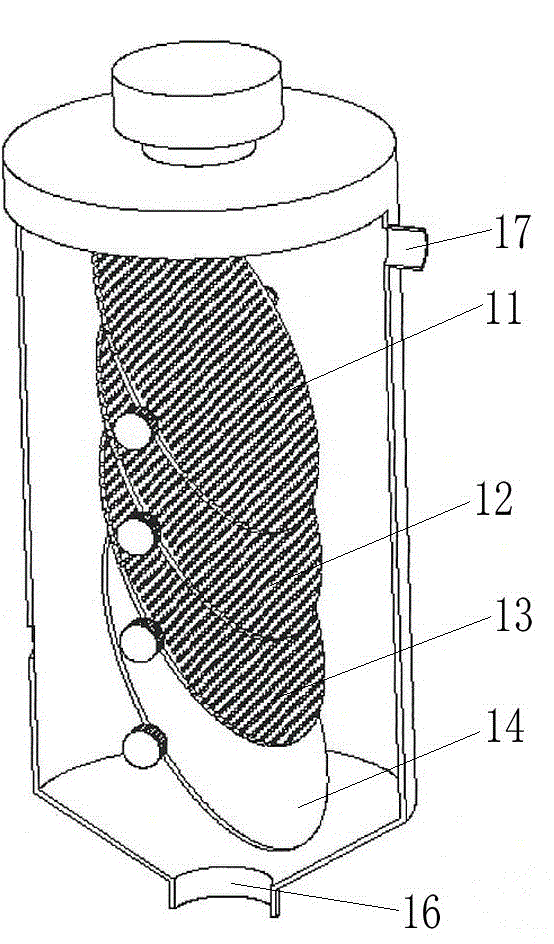

[0028] see figure 1 As shown, the present invention is composed of an automatic sand separator 1, a horizontal secondary sand separator 5, a liquid converter 2, a gas-liquid secondary separator 4, a gas collector 3, an oil-water separator 6 and an oil-water secondary separator 7 Composition; wherein, the automatic sand separator 1 is connected to the horizontal secondary sand separator 5 through the automatic sand separator liquid outlet 15, the horizontal secondary sand separator 5 is connected to the liquid converter 2 through the catheter tube 9, and the automatic sand separator exits The gas port 10 is connected to the gas-liquid secondary separator 4 through the air guide tube 8, the liquid converter 2 is connected to the gas-liquid secondary separator 4 through the liquid converter gas outlet 25, and the gas-liquid secondary separator 4 is connected to the gas collector 3; The liquid converter 2 is connected to the oil-water separator 6 through the liquid outlet 23, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com